Nedap SmartFlow / Installation manual

Version 01.001 / 2021 / EN

35

Dairy Farming

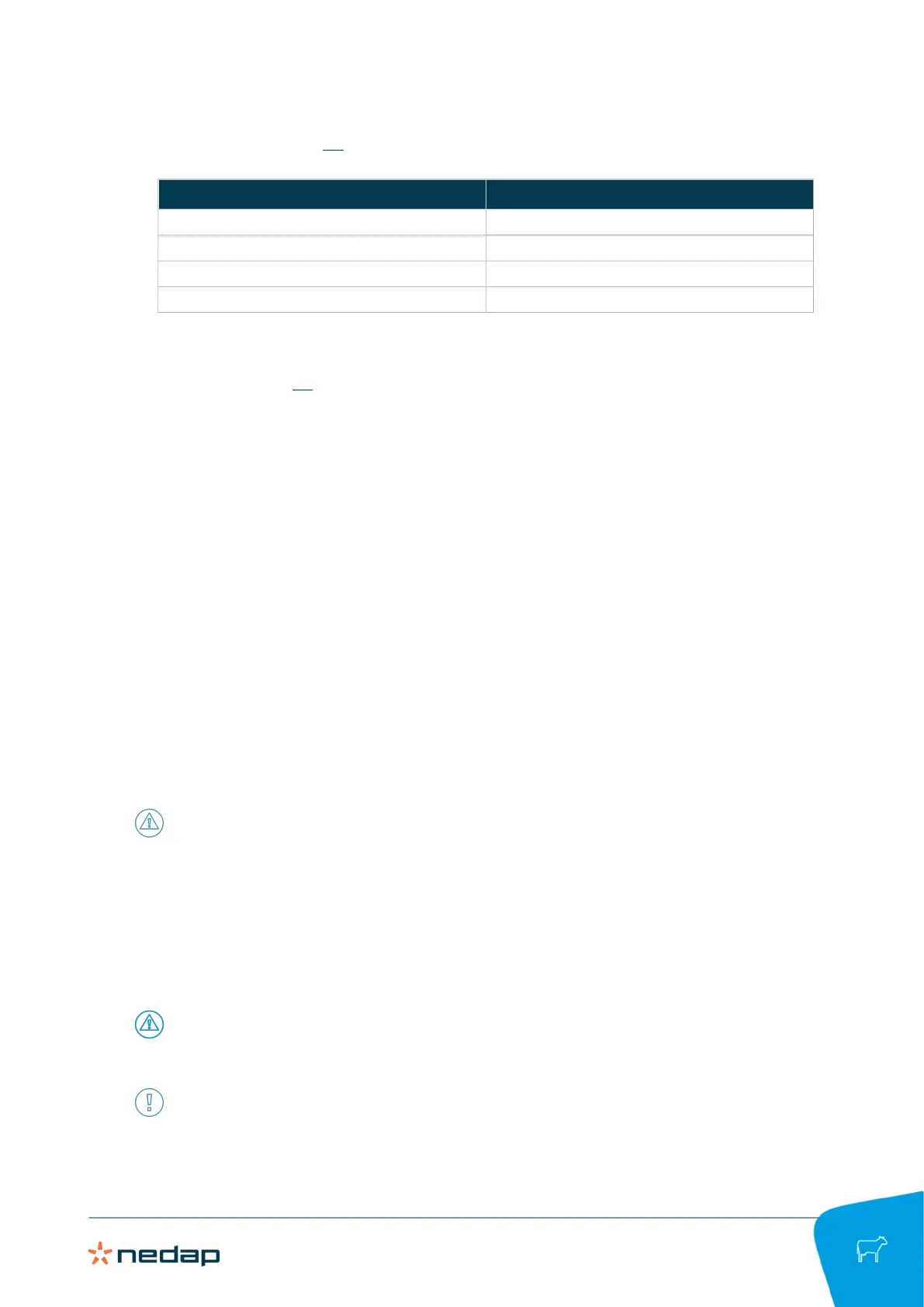

c. When the malfunction did not include replacement of the SmartFlow Float, check if recalibration is

necessary:

Malfunction Recalibration

Housing defect Yes

Housing dirty No

Cleaning valve defect No

Housing is tilted No

1. If recalibration is required: Follow the procedure in Calibrate the SmartFlow (page 30) and proceed

with step 6d.

2. If recalibration is not required: Go to step 6d.

d. In Velos go to Settings > Milking > Smartflows and select the milking parlor.

e. Go to the tab Overview.

f. Enter a remark about the malfunction of the SmartFlow.

g. Click Submit.

h. Go to Reports > Milking > Smartflows.

i. Select the range of milking points and click Ok.

j. Go to step 7.

7. Send the SmartFlow report to the certifying organization.

6.2 Check the Zero Point test

The Zero Point test can be used for the annual validation check of the SmartFlow milk meters.

Start the zero-point test:

1. In Velos, go to Settings > Milking > Smartflow settings.

2. Select the milking parlor.

3. Go to the tab Zero Point Test.

4. Click on the Start all Zero Point Tests button.

Caution

All SmartFlow milk meters must be tested annually!

The message Zero Point Test in progress .. is displayed for all milking points that are under test. The

progress of the 5 runs of the Zero Point test is shown between brackets (x/5).

5. If the test needs to be stopped while running, click on the Cancel button.

Execute the Zero Point test in the milking parlor:

1. Decouple the milk inlet tube from the milk claw.

2. Install an air compressor on the vacuum inlet (max. 300 mbar).

Warning

Do not exceed this pressure to avoid damage to your installation!

3. Pour drinking water in the milk inlet tube (minimum flow of 5 L/min and for at least 5 seconds)

The temperature of the drinking water must be ca. 10 °C (50 °F)

Loading...

Loading...