Step 3 – Install the AC Branch Circuit Junc�on Box

1. Install an appropriate juncon box on to the mounng plate.

2. Mount the adapter plate at a suitable locaon on the racking or frame. This

is typically near the end of a row of modules.

3. Feed the open wire end of the tail cable into the juncon box and secure with

an appropriate cord grip or strain relief ng. The AC tail cable requires a

strain relief connector with an opening of 3/8” in diameter.

4. Feed the connecng wires from either the main se

rvice panel or subpanel (if

mulple branch circuits are deployed) into the juncon box. This is most likely

via metal conduit.

5. Connect L1, L2 and Ground from the branch circuit to their corresponding

connecons from the electrical panel with wire nuts. NEP recommends the

applying sealant to the inside cavity of the wire nuts. Seal the juncon box.

Step 4 – Ground the System

Each BDM-600 has an integrated ground protecon circuit. The grounding wire is

through the trunk cable, and should be securely connected to the ground

connector in the juncon box.

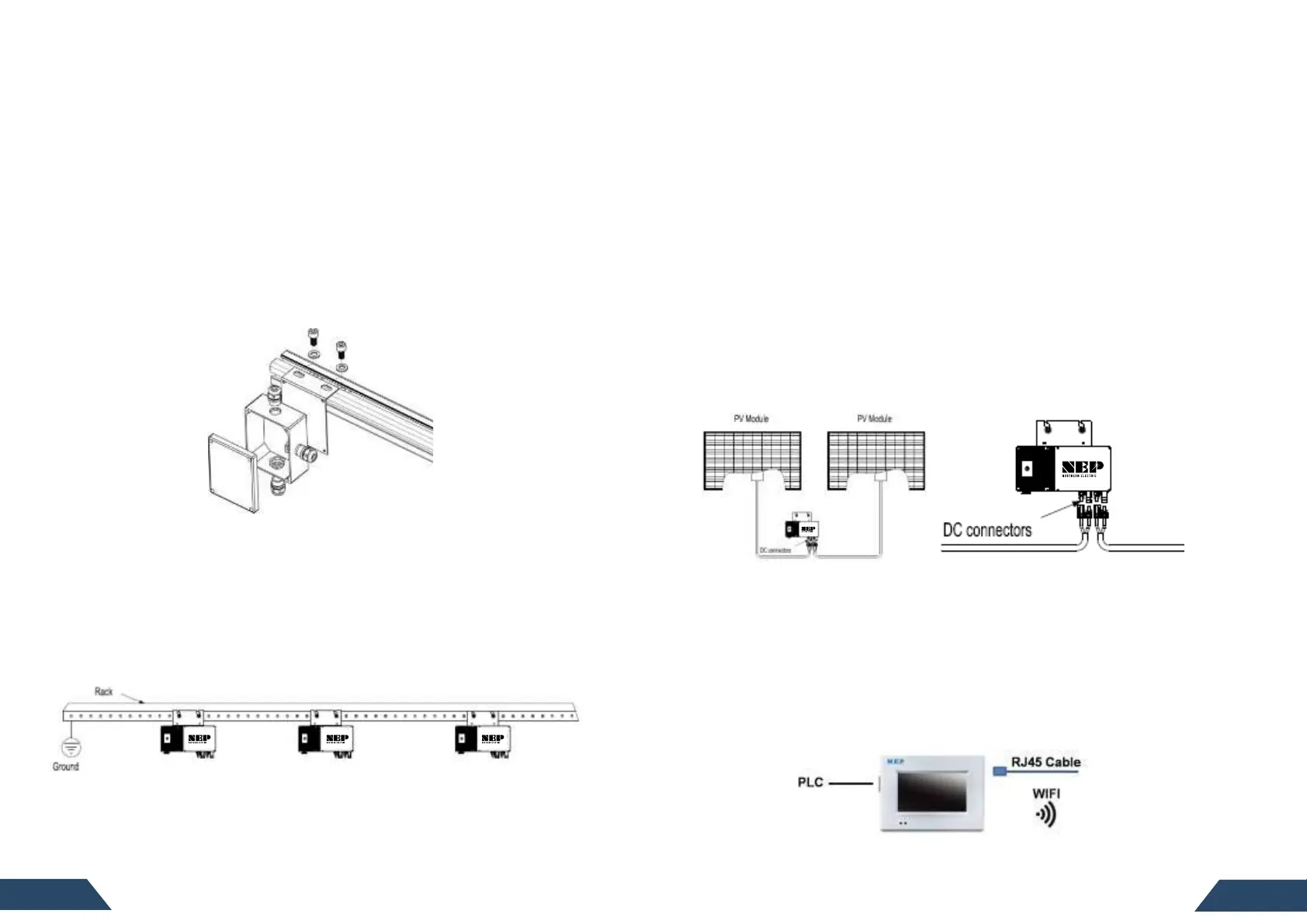

Ground the System Through Racking (Op�on)

BDM-600 may also be grounded through the racking as shown below.

Step 5 – Complete the Connec�on Map

Each BDM-600 has a removable serial number label located on the mounng plate

as well as addional sckers included in the microinverter’s protecve bag.

Remove one and ax it to the corresponding locaon on the layout map. Aer

entering this data, the BDM-256 will create a virtual array from the map you create.

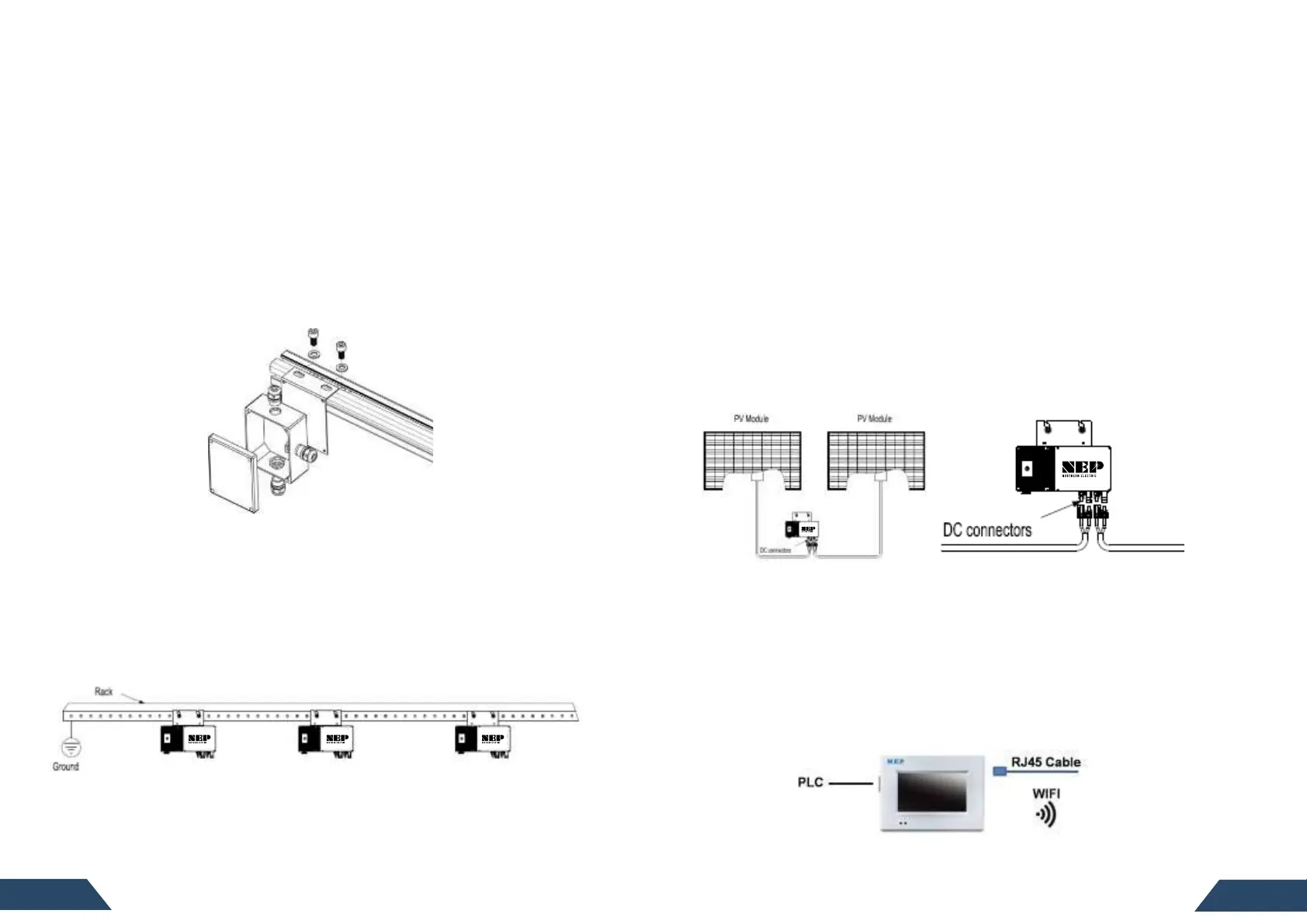

Step 6 – Connect the PV Modules

Connect all AC all system inter-wiring connecons prior to installing the PV

modules.

1. Mount the PV modules in the posio

ns corresponding to their associated

BDM-600 microinverter. Each BDM-600 comes with two sets of oppositely sexed

DC connectors.

2. Connect the posive DC wire from the rst PV module to the negavely marked

DC connector (male pin)on the BDM-600. Then connect the negave DC wire

from the PV module to the positively marked DC connector (female socket) of

the BDM-600. Next, do the same for the second set of DC connectors from the

second module. Repeat for all re

maining PV modules using one BDM-600 for

each set of modules. If the system contains an odd number of modules, it is

acceptable to connect only one PV module to the BDM-600.

Step 7 – Install the Monitoring Gateway

The BDG-256 (or BDG-256P3) is a versale gateway that connects each of the

BDM-600 microinverter to the NEP server via the cloud, allowing for collecon of

producon and other data useful in system monitoring and trouble shoong. It is

easily insta

lled either by plugging into an exisng 120V AC interior outlet or by

hardwiring into the 240V service in a suitable protecve enclosure. Connecng to

240V will maximize the strength of the PLC signal, thereby improving

communicaon. The BDG-256P3 is designed to support commercial three phase

systems and should only be located in a protecve enclosure. The gateway then

will connect to the server via either WiFi or direct Ethernet connecon.

Follow the instrucons in the NEP Gateway BDM-256/256P3 Installaon and

Operaons Manual for specidetails on registering the individual microinverters

in the PV system.

Loading...

Loading...