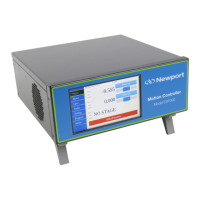

ESP302 Controller Start-Up Manual

5 A1270B1 - EDH0411En1021 – 02/20

2.0 System Overview

2.1 Specifications

•

1 to 3 axes of stepper or DC brush motors using internal drives

Communication Interfaces

• COMM. port (RS232)

• Front panel touchscreen interface

• Ethernet TCP/IP 10/100/1000 Base-T:

– One RJ45 connector with fixed IP address and DHCP server for local communication

– One RJ45 connector for networking, static or dynamic addressing with DHCP and DNS

Firmware Features

• Native user defined units (no need to program in encoder counts)

• Real time execution of custom tasks using program mode

• Multi-user capability

• Concept of sockets for parallel processes

• Data gathering at up to 10 kHz rate

Motion

• Jogging mode including on-the fly changes of speed and acceleration

• Line and arc modes for two axes trajectory motions

•

Master-slave including single master-multiple slaves and custom gear ratio

Compensation

• Backlash

•

Linear (All corrections are taken into account on the servo loop)

• 16 TTL 5 V configurable as inputs or outputs

Control Loop

• Open loop, PI position, PIDFF velocity, PIDDualFF voltage

• Integration limit and integration time

• Derivative cut-off filter

• GPIO configurable to start/inhibit motion, jog or program execution

Dedicated Inputs Per Axis

• RS-422 differential inputs for A, B and I, Max. 25 MHz

• Mechanical zero and limits

Drive Capability

• Voltage, velocity (for DC brush motor control).

• Position (for stepper motor control)

• 2x3A RMS @ 48V per axis

• 150 W (@ 230 VAC) maximum available power for all axes

AC Power Requirements

• 100–240 VAC 60/50 Hz 4.8 A–2.1 A.

The controller should be connected to a power

installation that incorporates appropriate pr

otection devices. Refer to the installation

requirements of your facility and local applicable Standards

Environmental

• Internal use

• Category II (2500 V max transient surges)

• 85% R.H. at 40 °C (Non-condensing)

•

• -20 °C to +55 °C (Non-condensing)

• Pollution Degree 2, exempt of conducting dust

• -20 °C to +70 °C (Non-condensing)

Loading...

Loading...