23

6 Maintenance

6.1 Instrument maintenance

• To clean the instrument, use only mild soap solution and rinse with water.

• Do not use detergents or high pressure washing equipment.

• At least once a year, check all your connections and apply additional silicon paste at

each connection point.

• When the instrument is not in use, always fit the instrument cover for protection

• Storing of instruments when not in use for longer periods: It is advisable to remove the

instruments and transducers and store them inside the boat or at home preferably at

room temperature.

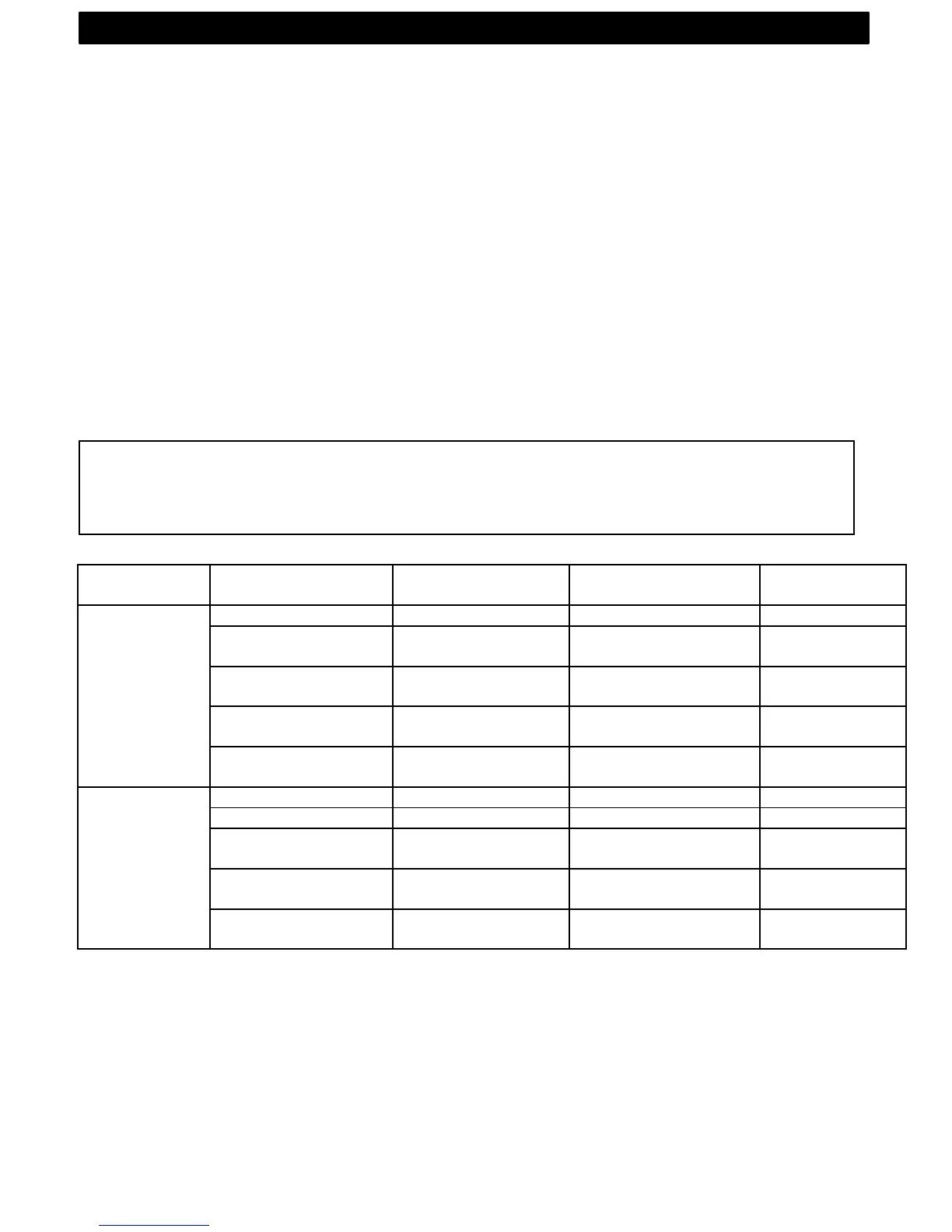

6.2 Drive unit maintenance and inspection schedule

If the boat does not accumulate below hours within 3 months, the frequency is every 3:rd

month.

Warning!

Failure to rectify any faulty conditions discovered as a result of the inspection could cause

sudden loss of Autopilot control, with consequential danger. It is recommended that all

items referenced in the following table be inspected before commencing any cruise.

Type Equipment Checks Remedy Inspection

frequency

Hydraulic Oil reservoir level Correct Fill 200 hrs

Oil condition Discoloration

Contamination

Flush system and

replace the oil

1000 hrs

1000 hrs

Hydraulic piping Damage

Leaks & Corrosion

Replace 1000 hrs

Hydraulic fittings Damage

Leaks & Loosening

Replace

Tighten

500 hrs

Piston rod seals

on pumpset

Leaking Replace 1000 hrs

Mechanical Linear drive Corrosion Replace or Repair 2000 hrs

Tiller arm Corrosion Replace 2000 hrs

Tiller bolts Corrosion

Loosening

Replace

Tighten

2000 hrs

500 hrs

Rod end bolt

on linear drive

Corrosion

Loosening

Replace

Tighten

2000 hrs

500 hrs

Trunnion bolts

on linear drive

Corrosion

Loosening

Replace

Tighten

2000 hrs

500 hrs

MAINTENANCE

Loading...

Loading...