CONNECTING THE BRINE SIDE

• The pipe connections are on the rear of the heat pump.

• Insulate all indoor brine pipes against condensation.

NOTE

Condensation may drip from the expansion

vessel. Position the vessel so that this does

not harm other equipment.

Caution

When necessary you should install venting

valves in the brine system.

• Mark the brine system with the antifreeze that is used.

• Install the supplied safety valve at the expansion ves-

sel as illustrated in the outline diagram. The entire

length of the overflow water pipe from the safety

valves must be inclined to prevent water pockets and

must also be frost-free.

• Install shut off valves as close to the heat pump as

possible so that the flow to individual cooling modules

can be shut off. Extra safety valves between the heat

pump and filterballs (according the outline diagram)

are required.

• Fit the enclosed filterballs on the incoming pipe.

• Fit the supplied non-return valves on the outgoing

pipe.

In the case of connection to an open groundwater sys-

tem, an intermediate frost-protected circuit must be

provided, because of the risk of dirt and freezing in the

evaporator. This requires an extra heat exchanger.

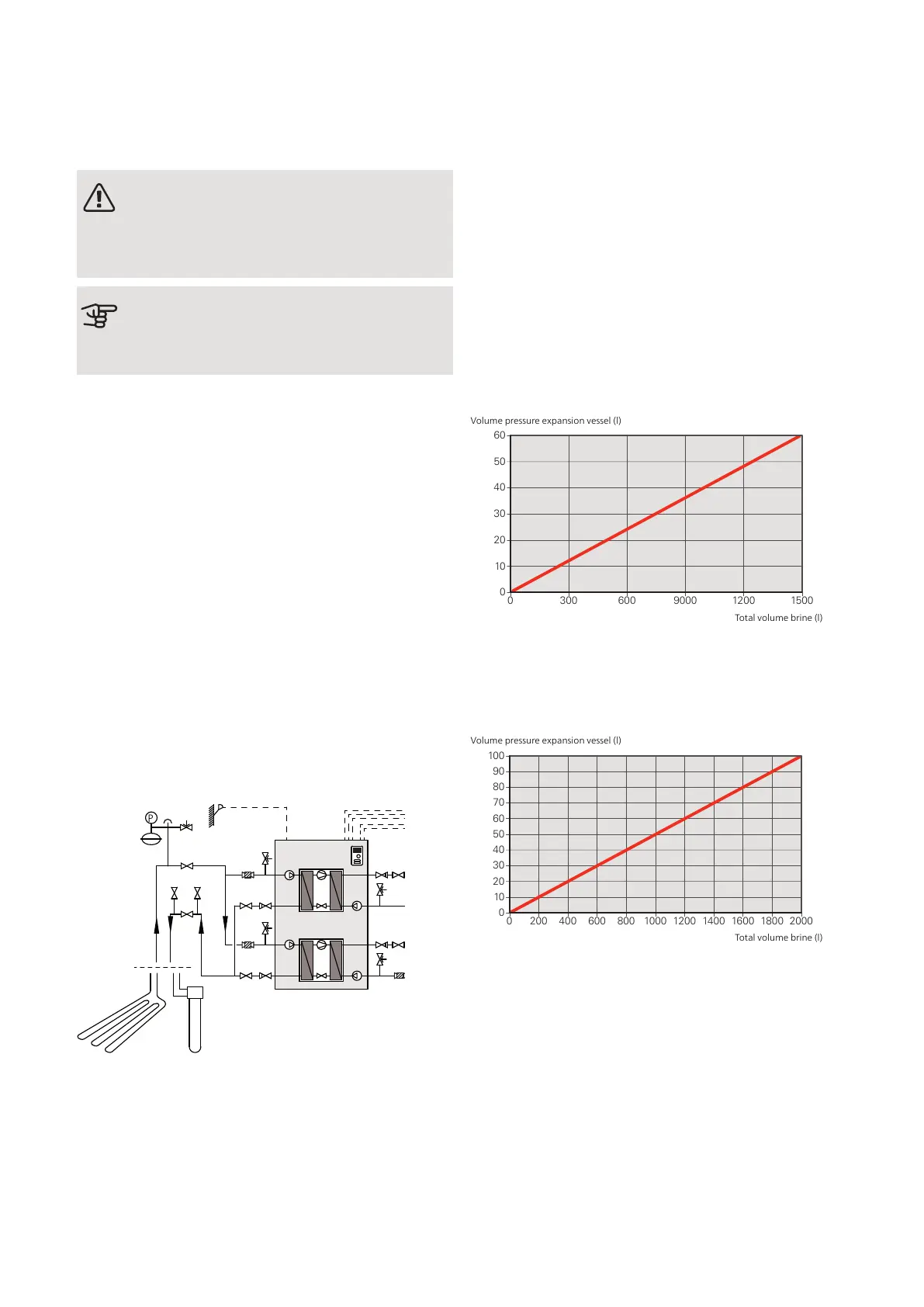

EXPANSION VESSEL

The brine circuit must be supplied with a pressure ex-

pansion vessel.

The brine side must be pressurised to at least 0.05 MPa

(0.5 bar).

The pressure expansion vessel should be dimensioned

as set out in the following diagram, to prevent malfunc-

tions. The diagrams cover the temperature range from

10 °C to +20 °C at pre-pressure 0.05 MPa (0.5 bar) and

the safety valve's opening pressure of 0.3 MPa (3.0

bar).

Ethanol 28% (volume percent)

In installations with ethanol (28% volume percent) as

the brine the pressure expansion vessel must be dimen-

sioned according to the following diagram.

0

0 300 600 12009000 1500

10

20

30

40

50

60

Volym tryckexpansionskärl

(l)

Totalvolym köldbärere i system

(l)

Volume pressure expansion vessel (l)

Total volume brine (l)

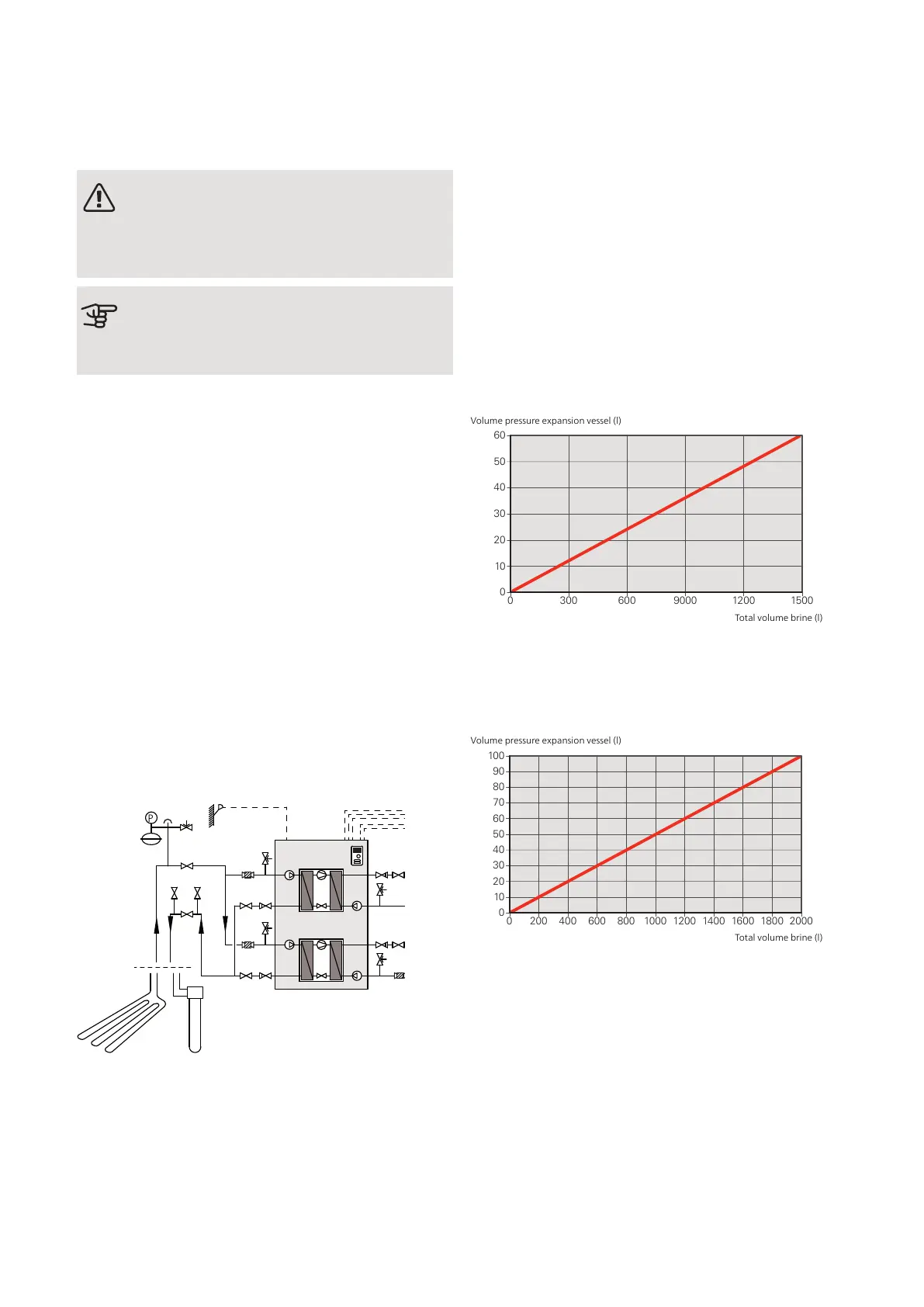

Ethylene glycol 40% (volume percent)

In installations with ethylene glycol (40% volume per-

cent) as the brine the pressure expansion vessel must

be dimensioned according to the following diagram.

0

0 200 400 600 800 1000 1200 1400 1600 1800 2000

10

20

30

40

60

70

50

80

90

100

Volym tryckexpansionskärl

(l)

Total volym köldbärare i system

(l)

Volume pressure expansion vessel (l)

Total volume brine (l)

17Chapter 4 | Pipe connectionsNIBE F1355

Loading...

Loading...