English – 10

English

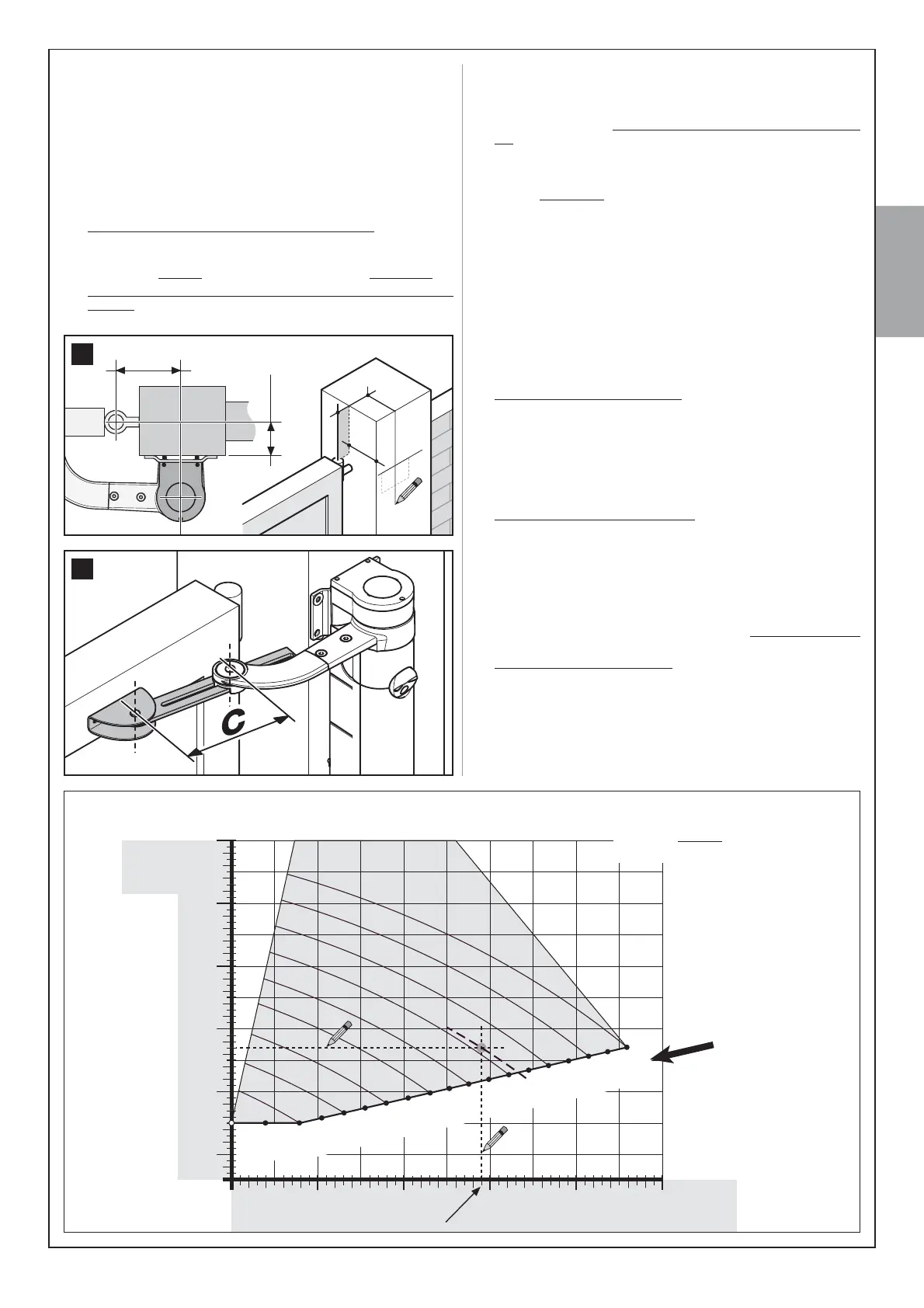

(*) Warning! - If the post surface width is between 80 and 135 mm,

ADENQDOQNBDDCHMFVHSGHMRS@KK@SHNMSGDQD@QFD@QLNSNQjWHMFAQ@BJDS

must be turned through 90°. Then follow the instructions in ƄJ.

b),@QJSGDjWHMFONHMSRCQHKKSGDGNKDRHMSGDONRS@MCHMRDQSSGDOKTFR

then secure the gearmotor using adequate screws and washers.

Note 7KHVFUHZVDUHQRWLQFOXGHGLQWKHNLWDVWKHLUW\SHGHSHQGV

RQWKHPDWHULDODQGWKLFNQHVVRIWKHSRVWLQZKLFKWKH\DUHƄ[HG

c) - For increased stability of the gearmotor, adjust its rear feet so that

they are placed against the post. This adjustment can be made later,

VGDMSGDBNMSQNKTMHSHRQDLNUDCEQNLHSRRD@SENQSGDjQRSSHLDO@Q@-

graph 5.4).

6KRUWHQLQJWKHOHQJWKRIWKHVORWWHGDUPƄJ

a) - Loosen the nut of the slotted arm, remove the stop and move the two

pins apart, checking that the distance between them is the same as

the obtained value C. Then tighten the nut, but only provisionally.

05. &KHFNLQJWKDWWKHOHQJWKRIWKHVORWWHGDUPLVVXIƄFLHQWƄJ

and 18).

a) - Move the gate leaf to the maximum leaf closing position against the

travel limit stop.

b)$WSDMCSGD@QL@MCLNUDHSTOSNV@QCRSGDKD@EOK@BHMFSGDjWHMF

bracket on the arm. Then, ƄUPO\SUHVVWKHFXUYHGDUPDJDLQVW

WKHOHDIƄJDuntil the two arms are completely extend-

ed;DSSO\IRUFHDWWKHMRLQLQJSRLQWHOERZƄWWLQJ&DXWLRQ

the arms are completely extended only when the elbow blocks

against its stop.

c) - Ensure that the gearmotor arm is level (ƄJE) and use a pencil

to mark the centre of the slots on the bracket (ƄJ), to enable

RTARDPTDMSjMD@CITRSLDMSRNEKD@EBKNRTQD

d)3GDMOQNUHRHNM@KKXjWSGDAQ@BJDSNMSGDKD@EVHSG@BK@LONQ@CGDRHUD

tape and move the leaf to the maximum opening position, against the

kNNQLNTMSDCSQ@UDKRSNO

e) - With the leaf in this position, check the gate as shown in ƄJ:

stretch a piece of string passing exactly above the two pins of

the slotted arm through to the leaf hinge pin. If the string is found

between the hinge pin and post in the area of the hinge pin (posi-

tion “BB” in ƄJ), extend the slotted arm by a few millimetres

(value “C”) and repeat the check. Repeat the procedure several times

HEMDBDRR@QXTMSHKSGDRSQHMFHRKNB@SDCADSVDDMSGDF@SDSQ@MRHSYNMD

and the leaf hinge pin (position “AA” in ƄJ), and until the arm no

KNMFDQBNLDRHMSNBNMS@BSVHSGSGDjWDCNARS@BKDADGHMCSGDONRS

06. &XWWLQJWKHVORWWHGDUPƄJ

After ensuring correct operation of the entire arm, cut the excessive

part of the slotted arm as described below.

a) 3Q@BD@KHMDNMSGDRKNSSDC@QLHMSGDDW@BSONRHSHNMRODBHjDCHMOG@RD

1 in ƄJ Then remove the arm from the bracket and cut the

excess section of the arm.

b) - After removing any burrs found after cutting, re-assemble the arm

components with reference to ƄJ.

07. )L[LQJWKHDUPRQWKHOHDIƄJ

a) - Drill the leaf at the marked points; remove the bracket from the arm

@MCjWHSSNSGDF@SDKD@EVHSG@CDPT@SDRBQDVRNote 7KHVFUHZV

DUHQRWLQFOXGHGLQWKHNLWDVWKHLUW\SHGHSHQGVRQWKHPDWHULDODQG

WKLFNQHVVRIWKHSRVWLQZKLFKWKH\DUHƄ[HG

b)%HWSGD@QLSNSGDAQ@BJDSHMRDQSHMFSGDOHM@MCRSNOADMYHMFImpor-

tant - Check that the bracket and arm are perfectly level. If neces-

sary, loosen the bracket screws and level as required.

c) /DQL@MDMSKX@MBGNQSGDSQ@UDKRSNORSNSGDkNNQ in the same position

as established at the beginning of paragraph 3.4.

08. Checking perfect leaf closure.

a) - Close the leaf completely and ensure that it is placed against the trav-

el stop; then shake by hand to check and ensure that the gearmo-

SNQQDL@HMRjQLKXHMONRHSHNM(ESGHRHRMNSRNOQNBDDC@RCDRBQHADC

below; otherwise skip to phase 09:

1.QDLNUDSGDRKNSSDC@QLEQNLSGDjWHMFAQ@BJDSNMSGDKD@E

2. loosen the bracket screws and move it by a few millimetres in the

direction of the gearmotor;

A

0

50 100 150 200 250

B

C

300

250

200

150

10 0

50

80

100

120

140

160

180

200

220

240

260

mm

B = 145

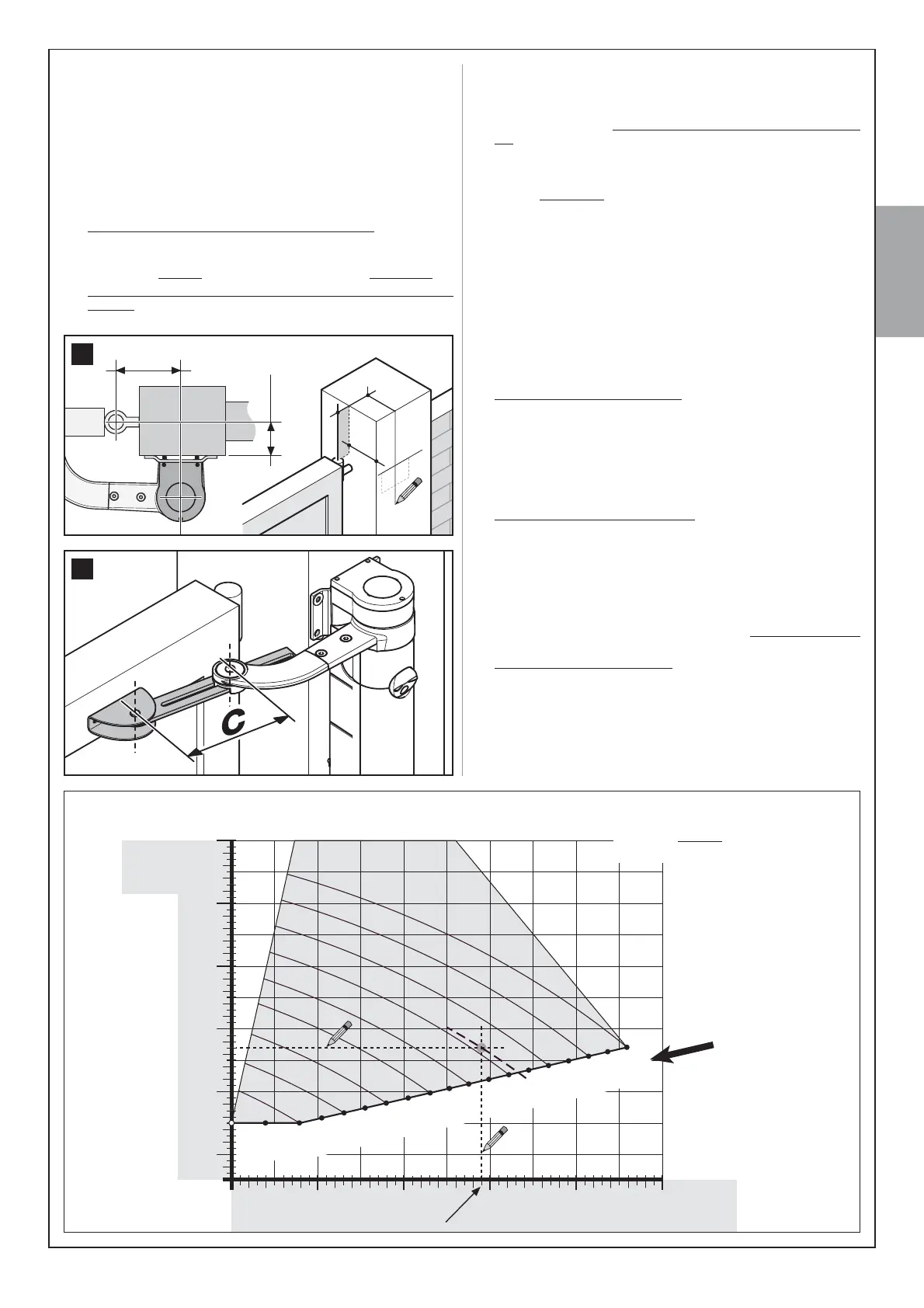

*5$3+(see paragraph 4.1B)

EXAMPLE: if value B on the gate post

is measured at mm and value A is

135 mm value C will be 210 mm

1

A

B

A

B

11

Loading...

Loading...