12 Commander C200/C300 Step By Step Guide

Issue Number: 2

The drive must be connected to the system ground of the AC supply. The ground wiring must

conform to local regulations and codes of practice.

Table 6-2 Protective ground cable ratings

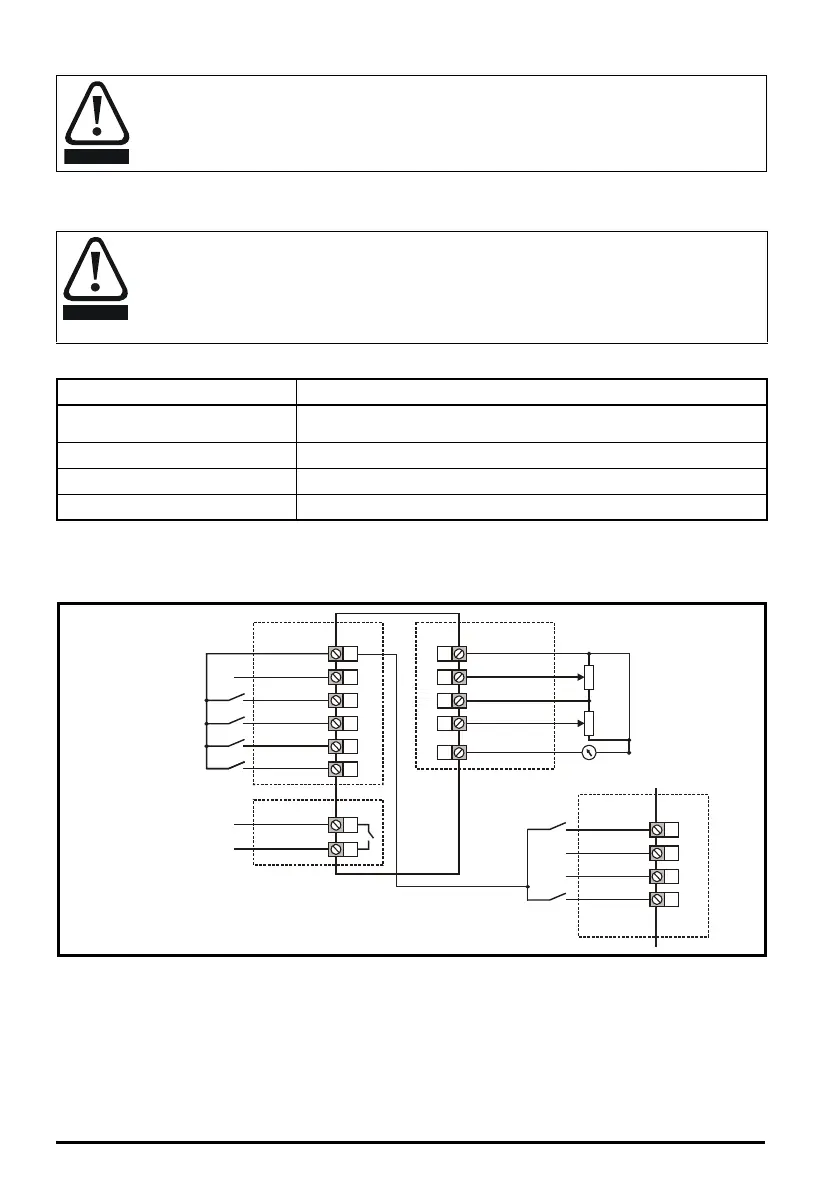

Control connections

The control terminals are configured by default for the arrangement shown below:

Figure 6-5 Commander C200/C300 control terminal connections

* 250 Vac maximum (UL class1)

** Commander C300 uses ‘Safe Torque Off’ so terminal 11 is unassigned on the Commander C300. When using a

Commander C300 refer to the 'Safe Torque Off' wiring instructions above.

After completing step 6 re-fit the terminal cover (refer to step 5).

Electrochemical corrosion of grounding terminals

Ensure that grounding terminals are protected against corrosion i.e. as could be caused

by condensation.

The ground loop impedance must conform to the requirements of local safety regulations.

The drive must be grounded by a connection capable of carrying the prospective fault

current until the protective device (fuse, etc.) disconnects the AC supply.

The ground connections must be inspected and tested at appropriate intervals.

Input phase conductor size Minimum ground conductor size

≤ 10 mm²

Either 10 mm² or two conductors of the same cross-sectional area as the

input phase conductor

> 10 mm² and ≤ 16 mm²

The same cross-sectional area as the input phase conductor

> 16 mm² and ≤ 35 mm² 16 mm²

> 35 mm²

Half of the cross-sectional area of the input phase conductor

9

10

11

12

13

14

41

42

1

2

7

4

5

31

32

35

36

24 V user

Zero frequency

Drive enable**

Run forward

Run reverse

Analog input 1/

Analog input 2 select

10 kΩ

10 kΩ

Frequency

reference 1

Frequency

reference 2

Frequency output

Digital I/O

24 V user

Digital I/O1

Digital Input 2

Digital input 3

Digital input 4

Digital input 5

Analog I/O

0V

Analog input 1

10 V user

Analog input 2

Analog output 1

Drive ok

Relay 1*

Safe Torque

Off

ST01

0V

STO1

0VSTO2

ST02

** C300 only

Loading...

Loading...