Usermanual NIMOS Micro-Trac Page 15

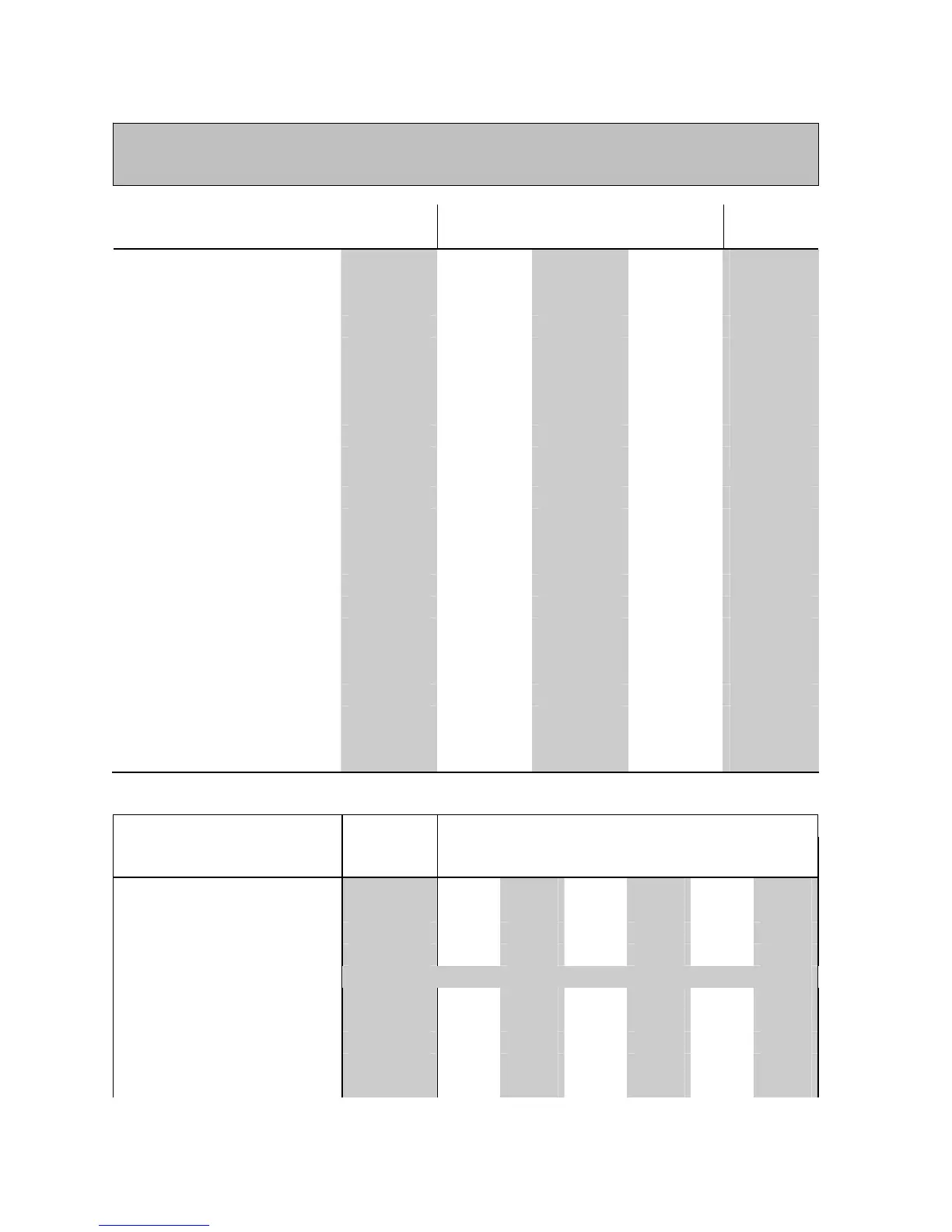

6.4 Maintenance diagram

First Every Every

Frequency

10 hours 50

M

hours 250 hours 500

Y

hours 5 years

fuel tank C

hydraulic oil tank / level V V

Battery liquid V V

parking brake V V

Neutral position transmission V V

lighting V V

instrument panel V V

tire pressure V V

hydraulic hoses (damage/leakage) V V R

clearance pivot frame (under steering

platform) and wheel bearings

V

Tighten wheel nuts

V

hydraulic system V

Suction filter hydrostatic transmission R

Y

Suction filter gear pump

e

C R

return flow filter element R

filling cap hydraulic tank R

hydraulic oil R

Driving pedal (1) G

propel shaft (1) G

ball joints tipping platform (4) G

Tipping cylinder mounting (5)

G

hinge bonnet (2) G

hinge cabin doors (4) G

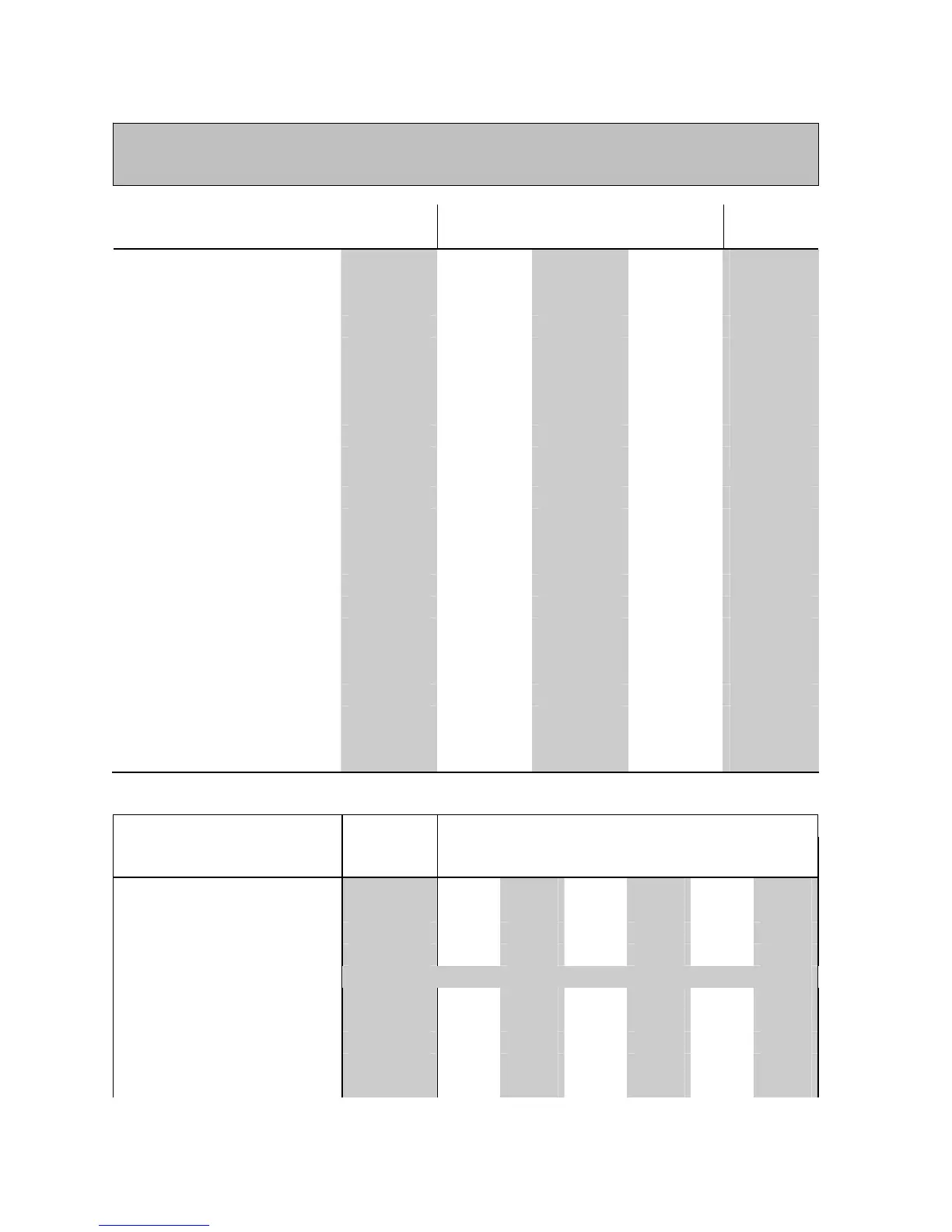

DIESELMOTOR Yanmar 3TNE68 (Always use manual of manufacturer)

1st Service

Frequency

50 our 100

3M

our

200

6M

our

400

J

our

500 our 800 our 1000

our

Motor oil V V

V-belt C C V

oil filter V V

Fuel filter V

Air filter Clean with every service interval

Radiator R

cooling system C C

Valve clearance C

Nozzles C

Radiator hoses and fuel hoses V

Note! Maintenance can be carried out by: Driver 50 our interval

Other interval by authorised NIMOS dealer

Loading...

Loading...