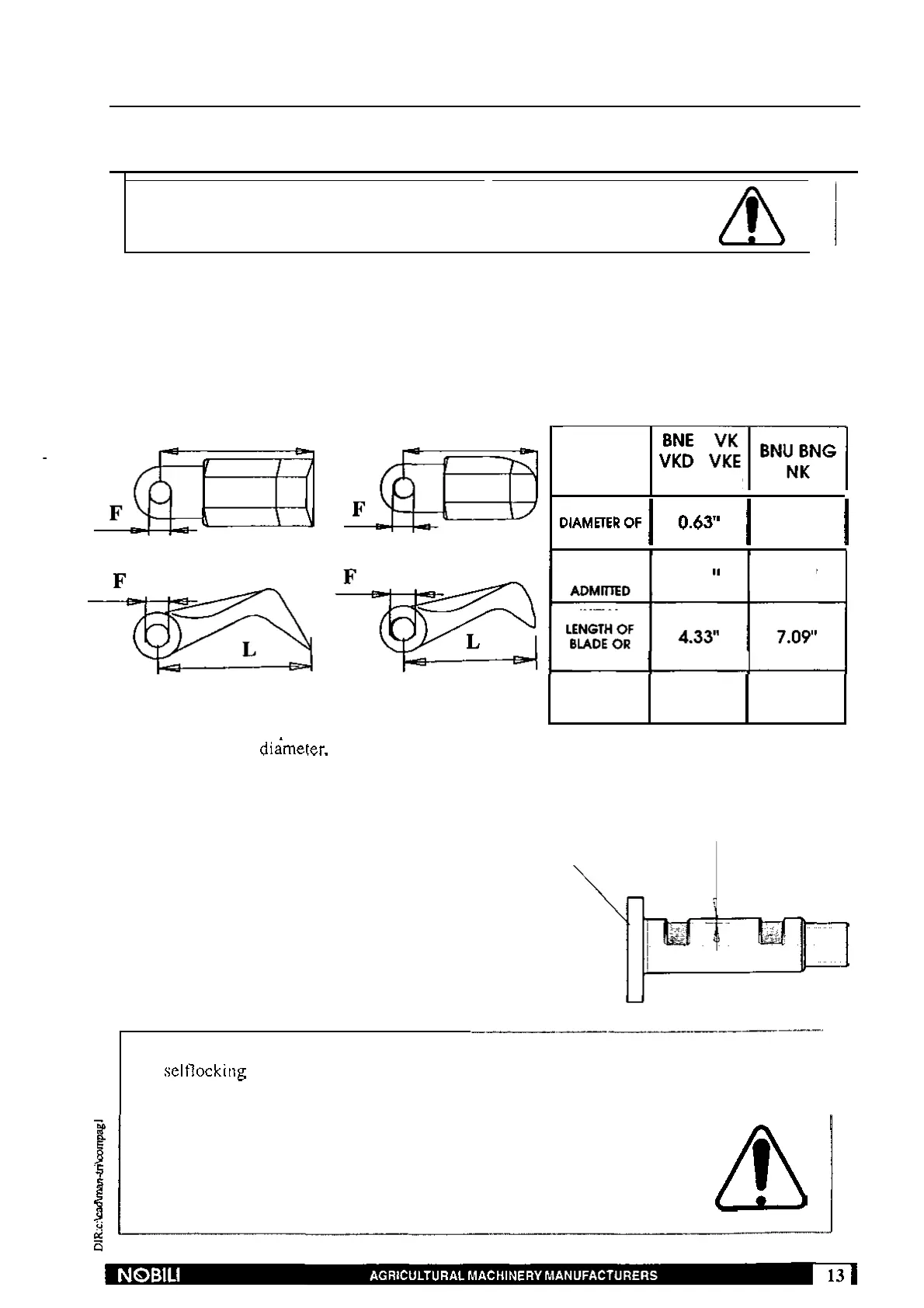

CHECK BLADES

OR

RAMS

AND THEIR FASTENING ELEMENTS

I

Worn blades

or

rams:

Blades or rams: to be checked always before using the machine

:

to

be

checked immediately after

an

obstacle

MINIMUM

ACCEPTABLE

LENGTH

3.54

"

5.92

"

Shreddingquality,machine

integrity

andsafety

depend

on

the care which will

be

devoted to these elements.

They must

be

replaced immediately

if

damaged.

Normal

wear(special1yrapid on sandy grounds or working with

the

machinetoo low) and bumps against

obstaclescan cause distortions or cracks

in

the blades

or

rams, which can lead

to:

Worsening

in

the work quality

Increase

in

vibrations and consequent mechanical damages

in

the

machine

Total or partial break of

the

blades and rams with consequent

projection

of

fragments at high speed.

L

L

MACHINE

WMU

VKR

INITIAL

THE

HOLE

1"

MAXIMUM

DIAMETER

0.7

1

1.07

"

INITIAL

HAMMER

I

from the original

The length

(L)

of

the

blade or ram should

not

be reduced

over

0.8

"

.

H

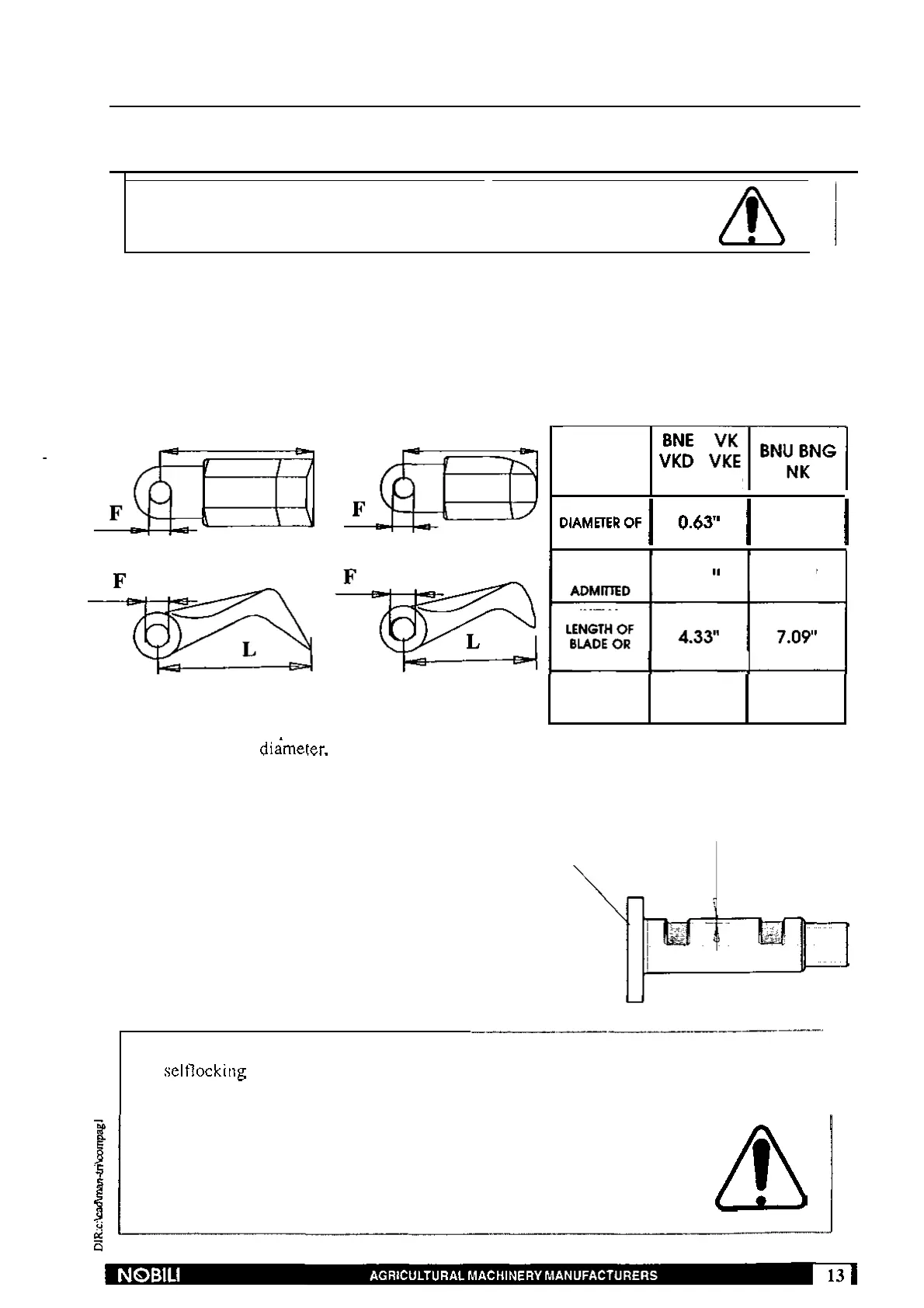

The pin fixing can be carried out with split pins or

nuts, according to the model

of

the machine.

Pins should be replaced if:

They

are

clearly

bent

or damaged

in

the thread:

in

particular

check

(if

welded) the welding integrity

of

the

plate

(S).

The

tracking made by the wear of the blade or ram

(H)

is

greater of

0.08

".

S

I

I

,

During

assembly:

The split

pins

or

nuts

shouId

be

changed

every time.

Torque wrench setting for

MI

6

nut:

75

Ib-ft

Torque wrench setting for

M20

nut:

180

Ib-ft

Check

that

the

pin

with tooth

or

the pin with hexagonal head,

CANNOT rotate

in

their seat on

the

support,

because this

could cause

an

abnormal

consumption.

Loading...

Loading...