Nordson Asymtek

Mini and micro dispensing solutions for fluids and pastes

page 11 off 20

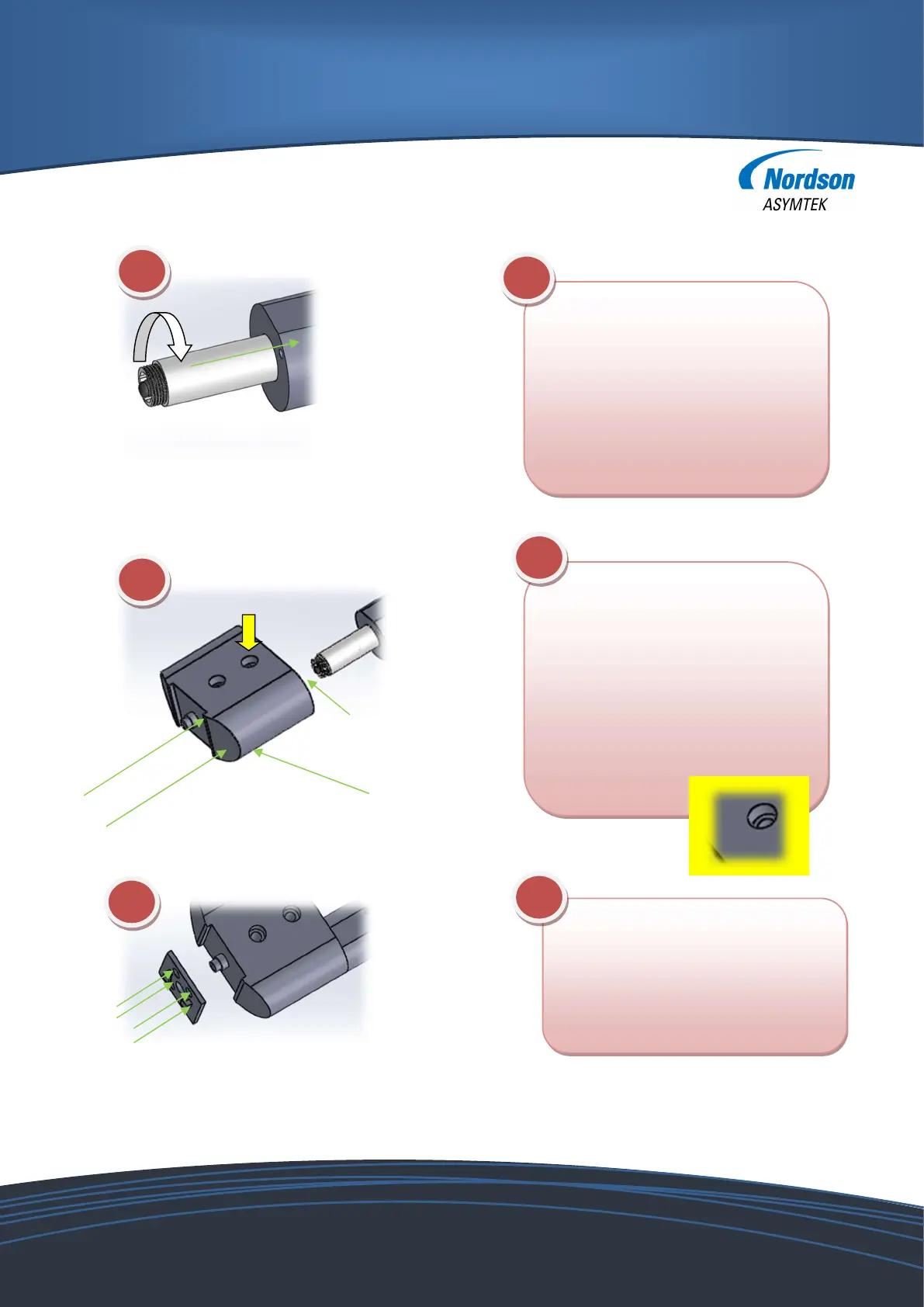

gently onto the rotor (3).

Please note, that the pump housing

(9) may be made of POM. Do not use

high force. Use Teflon on the threads

to seal better.

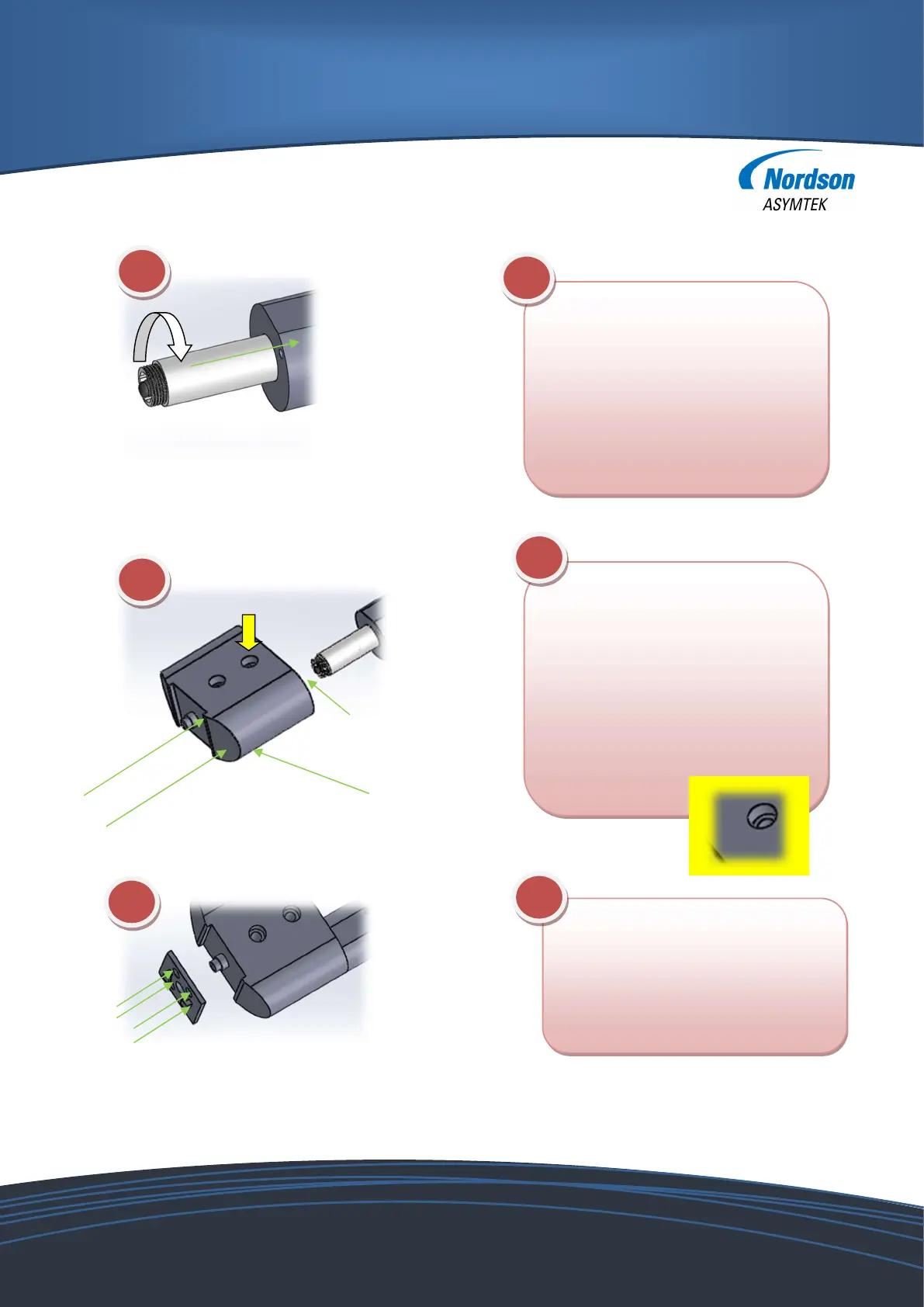

the mixer support plate (27) with the

mixing block (26). Do not use high

force!

3 Rotor

assembly

connect the pumps (9) with the

mixing block (26). There may be a

seal (37) needed before you enter

the stator (10) into the block.

Do not use high force!

Check the correct position of the

mixing block (26). The 2 holes can be

used for mounting

Loading...

Loading...