Nordson Asymtek

Mini and micro dispensing solutions for fluids and pastes

page 14 off 20

4.2 Dismantling (for cleaning or after wear)

Should your aCCura show irregular dispensing results and a recalibration does not help, then

possible wear of the stator may be the reason for inaccurate results. On top. leakage of fluids

thru the nozzle and increasing pulsation may be indications of wear of the stator.

Start dismantling the pump in the opposite way of 4.1 but skip H. Do only dismantle the

motor with driver in case you fear the motor and/or driver are malfunctioning.

Please be aware, that the motor might be hot!

Notices: Should the dispensing material not be black but you can see black residual

parts on the rotor, then this may be an indication for incompatibility of the material

with the stator elastomer. Ask your dealer!

Never smell the product to check the compatibility consistency!

Do not touch the material with bare hands!

Clean only with a soft cloth. Only use solvents compatible with POM. Do not use any hard or

metal brush to clean out the threads or any parts; this may destroy the parts.

Use protective gloves!

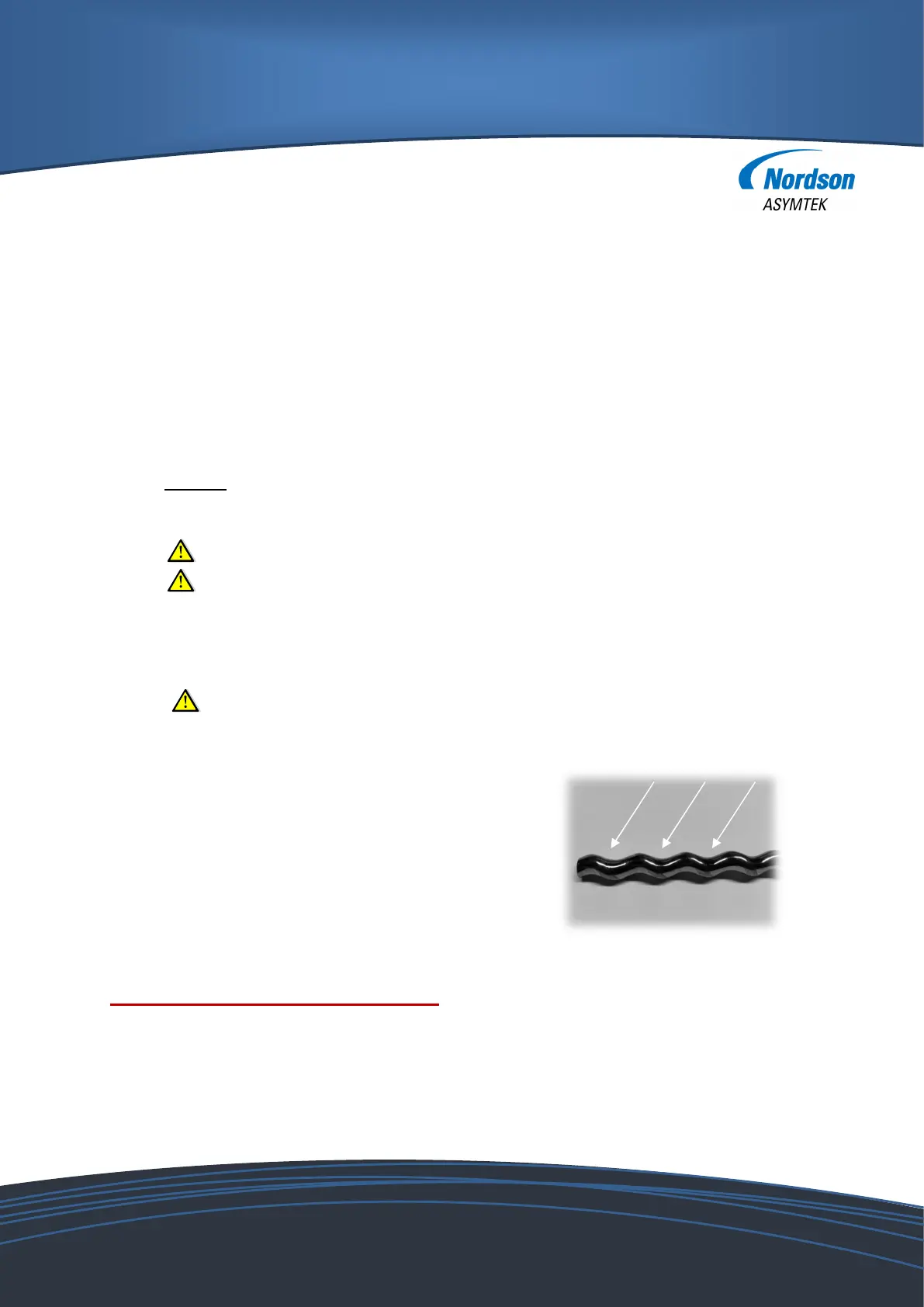

Clean the visible part of the rotor and check if you can detect any wear.

If you can see and feel wear like in the picture

then you will have to exchange the rotor-drive-shaft.

Generally, the stator (10) needs exchange in that case.

Only in little cases, the wear shown in the picture does not

result in refurbishement.

If only the stator (10) needs to be exchanged, please refer to point 4.1.1.1 for assembly.

Important notice about the seal:

Avoid the seals getting damaged by assembly and dismantling. Only use gentle force by

hand and no tools to release the seal(s).

Loading...

Loading...