20

Exhaust

Chimney Kit (3 in.): IFCK03xx,

Flexible Pipe PP (3 in.): IFVL03xxx

Intake

Termination**: ISELL0387UV, ISTT0320,

Bird Screen: IASPP03

Exhaust

&

Intake*

Single Wall Pipe (3 in.): ISVL03xx(UV),

ISEP03xx

Elbow (3 in.): ISELL0387UV, ISELL0345UV,

ISEL0387, ISEL0345,

Increaser: ISIA0203

- Centrotherm - lnnoFlue® PP

* Recommended items.

** Applicable vent termination are “87° elbow” or

“Tee type”.

Concentric vent termination of polypropylene

are prohibited.

Exhaust

Flex Chimney Lining Kit (3 in.): 3PPS-FKL,

Flex Length (3 in.): 3PPS-FLEXxx

Intake

Aluminum Flex Length (3 in.): 3DFA-xx,

Coupler (3 in.): 3DFA-FCP

Exhaust

&

Intake*

Elbow (3 in.): 3PPS-E45L, 3PPS-E90L,

Single-Wall Pipe (3 in.): 3PPS-xxL

Appliance Adapter for PVC Coupler (2 in.):

2PPS-ADL,

Increaser: 2PPS-X3L

- DuraVent® - Flex Through Chimney w/ Air Intake

For flexible pipe for chimney

• During the installation, ambient temperatures

must be greater than 40 °F (5 °C). Afterwards,

installation site ambient temperature must

be greater than -4 °F (-20 °C). Flexible vent

pipe breakage may occur if these temperature

requirements are not observed.

• Only listed manufacture specified vent parts

may be used for this appliance. Refer to the

manufacture’s literature for detailed information.

NOTE

Covering non-metallic vent pipe and

fittings with thermal insulation is

prohibited.

• Use only solid PVC / CPVC (schedule 40) or PP

pipe.

• 2 in. or 3 in. schedule 80 pipe may also be used

on this Combi Boiler, however the Btu/h input of

the Combi Boiler will be reduced by up to 9%.

• Maintain the same vent pipe diameter from the

Combi Boiler flue to the termination.

• In Canada, plastic vent systems must be certified

to ULC S636. The components of the certified

vent system must not be interchanged with other

vent systems or unlisted pipe/fittings.

• In Canada, specified primers and glues of the ULC

S636 certified vent system must be from a single

system manufacturer and not intermixed with

other system manufacturer’s vent system parts.

6.2.2 Installation Instructions

• Follow all general venting guidelines as outlined in

this manual.

• Clearance described in this document is the

minimum recommendation/required distance.

Take appropriate clearance according to the

situations of the site.

• Make sure the vent system is gas tight and will

not leak.

• Support the vent pipe with hangers at regular

intervals as specified by these instructions or the

instructions of the vent manufacturer.

• All piping must be fully supported. Use pipe

hangers at a minimum of 3 ft (0.9 m) intervals.

CARBON MONOXIDE POISONING

• Failure to properly seal the vent system could

cause flue products to enter the living space.

• (For flexible pipe for chimney)

Handle the flexible vent carefully.

Dropping, Crushing and Stacking may cause

damage, and may result in fires, property

damage or exposure to Carbon Monoxide.

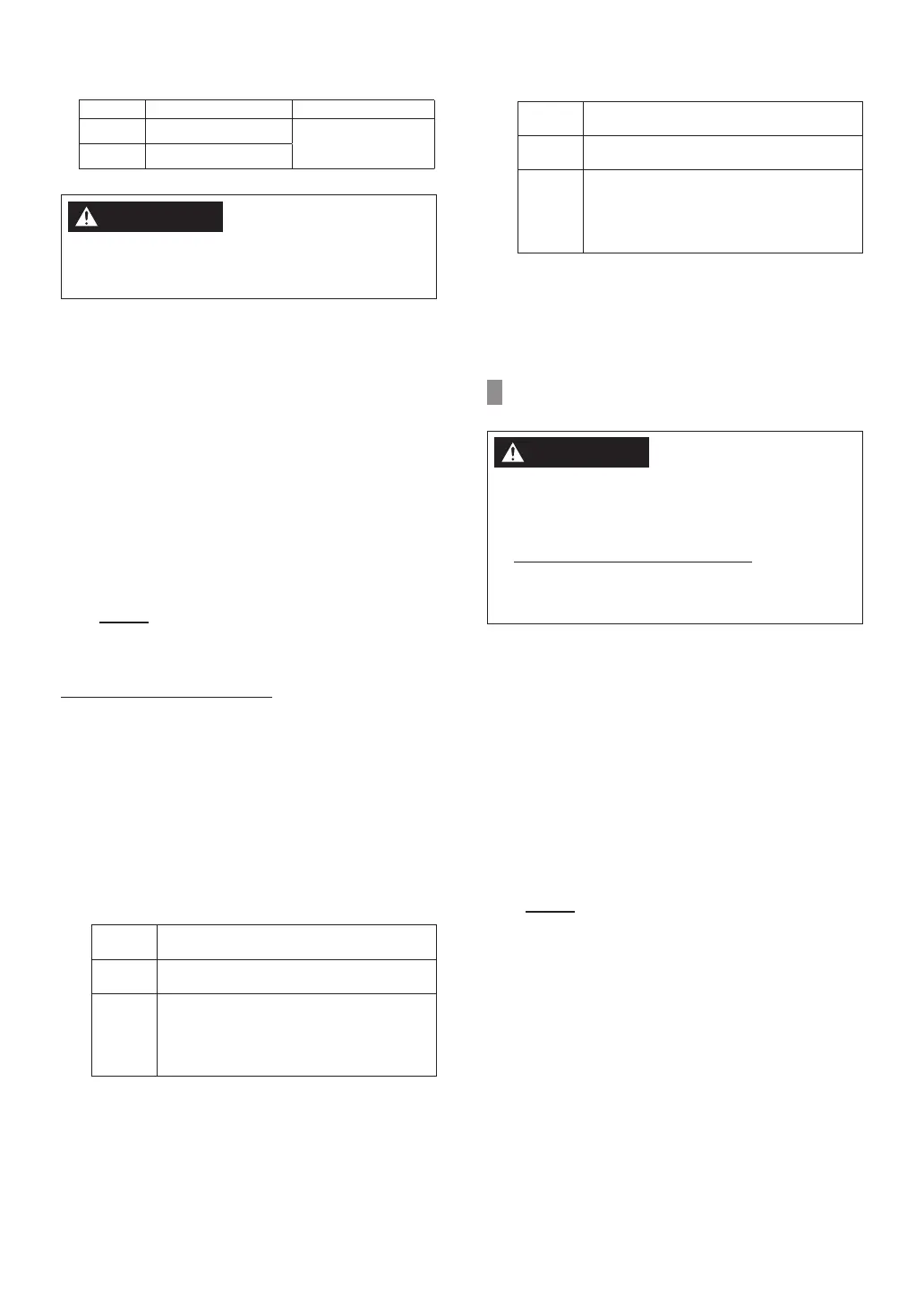

WARNING

NOTE

• Do not use the Combi Boiler to

support the vent piping.

• Do not common vent or connect

more than one appliance to this

venting system.

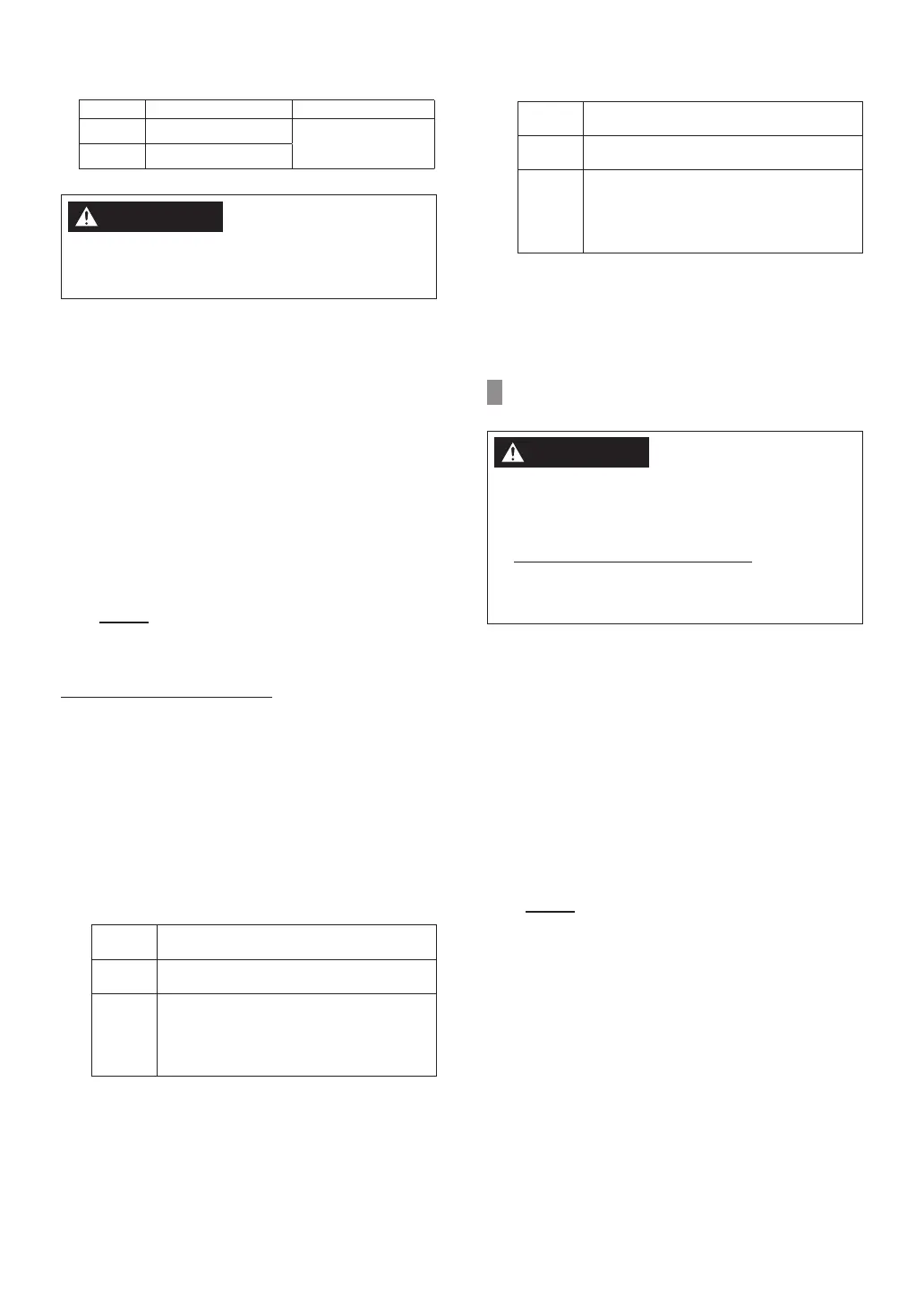

[Pipe Cement / Primer]

Material United States Canada

PVC ANSI/ASTM D2564

ULC S636

Certified Materials

Only

CPVC ANSI/ASTM F493

Use of cellular core PVC (ASTM F891), cellular

core CPVC, or Radel® (polyphenylsulfone) in

non-metallic venting system is prohibited.

WARNING

Venting the Combi Boiler

Loading...

Loading...