HYDRAULIC INSTALLATION

HYDRAULIC QUICK DISCONNECTS

NPK recommends against the use of non-NPK quick disconnects on hydraulic circuits

operating NPK Products, including Compactor/Drivers for the following reasons:

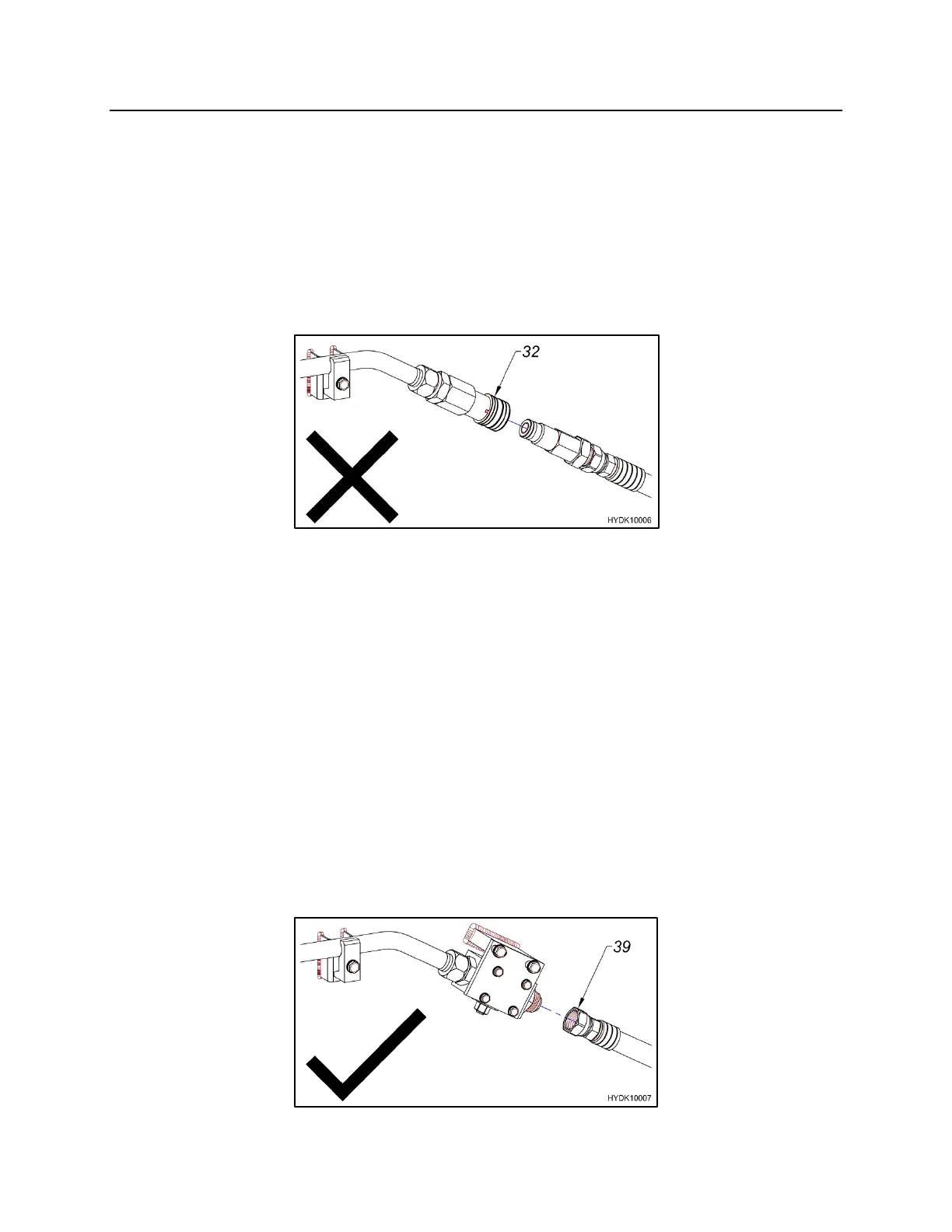

1. Compactor/Driver operation can cause internal pieces of a non-NPK quick

disconnect (32) to disintegrate. These pieces can migrate into the Compactor/Driver

hydraulic motor, causing damage.

2. If quick disconnects are used when the Compactor/Driver is removed from the

carrier, the disconnects should be capped to keep them clean. If this is not done,

contamination in the disconnect will be flushed into the Compactor/Driver when

reconnected, also causing damage.

3. Quick disconnects create a restriction in the hydraulic circuit. NPK

Compactor/Drivers are back pressure sensitive. Restrictions can cause damage to

the hydraulic motor.

4. The pressure required to operate the Compactor/Driver, plus the restriction of the

quick disconnects may push older, low pressure carriers to the limit of their hydraulic

system, interfering with Compactor/Driver Operation.

5. Quick disconnect restrictions can cause unnecessary heating of the carrier’s

hydraulic system.

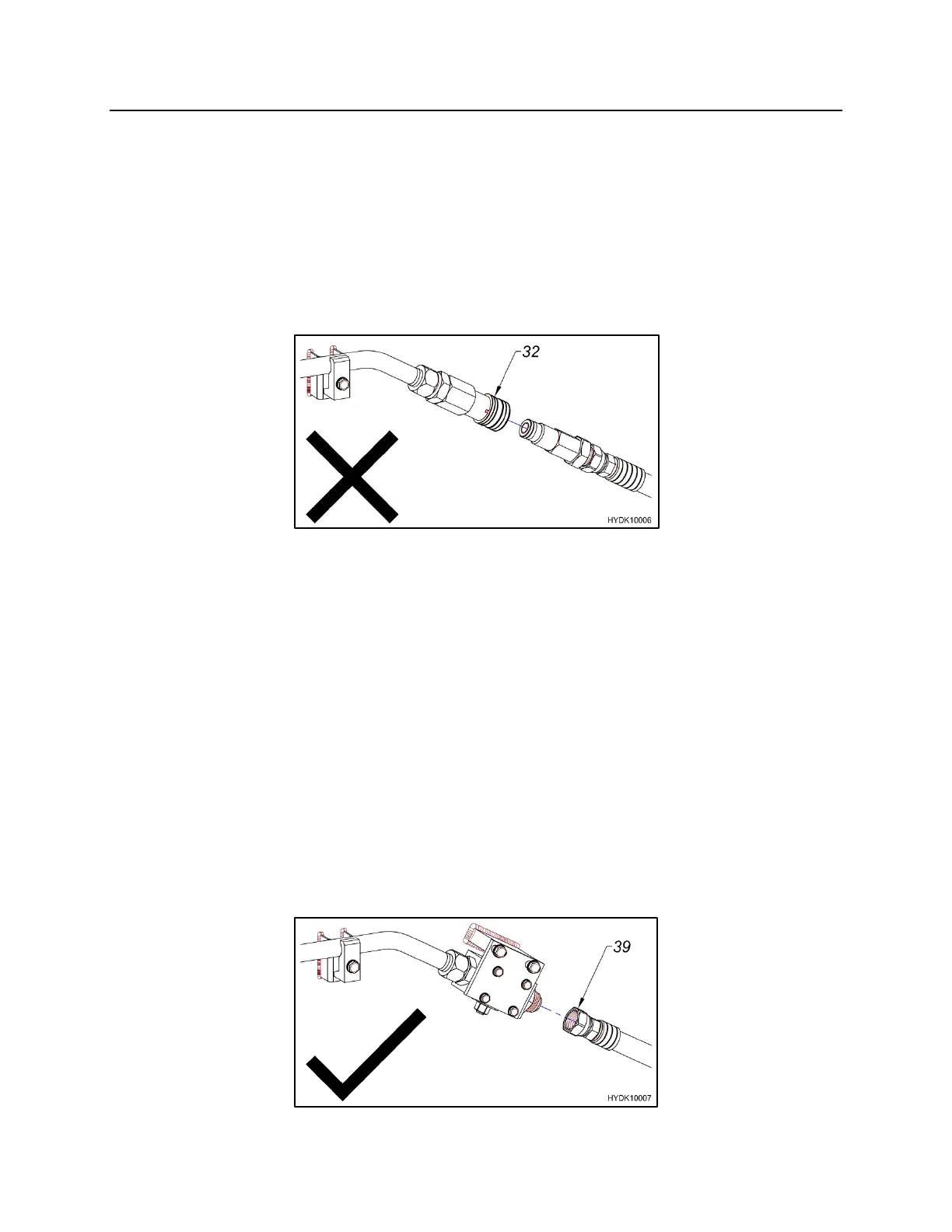

NPK encourages the use of a standard hose and fitting connection (39). It is

recommended that when the Compactor/Driver is removed from the carrier, the tube

ends and hose fittings should be capped and plugged to keep them clean.

Loading...

Loading...