13

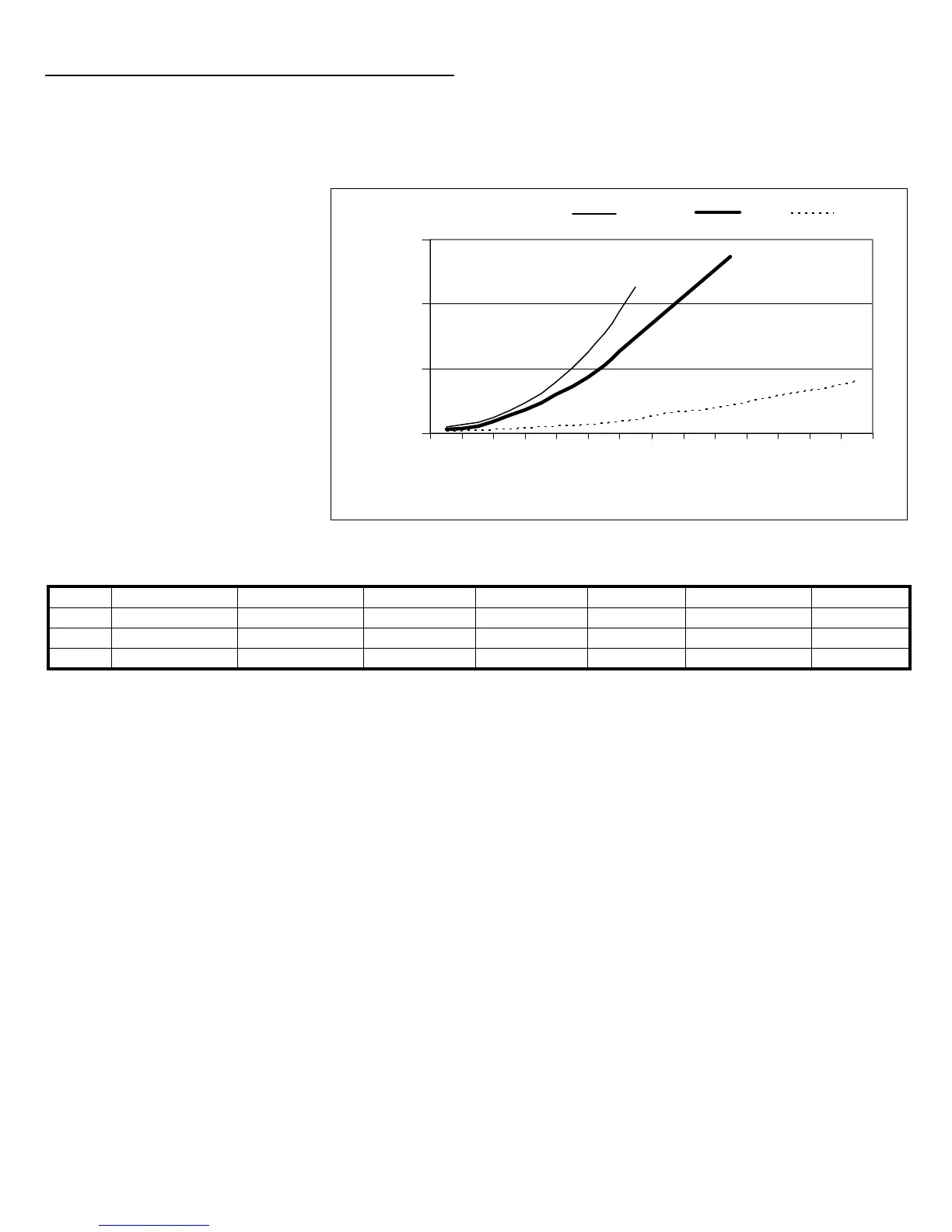

Trinity Head Loss

0

20

40

60

2 4 6 8 10 12 14 16 18 20 22 24 26 27

GPM us

Feet of Head

Ti100-150 Ti200 Ti400

The Trinity boiler comes in two versions, Heating and Combi.

Heating Version – The standard heating version is designed to operate in a hydronic heating system and can operate with an indirect

water heater.

Combi Version – This special version is equipped with internal components to provide hydronic heating and domestic hot water heating.

See Sections 6.1 and 6.3. (Not available on Ti100 & Ti400 Models)

6.1 Primary Loop Plumbing

Circulating Pump Due to the Trinity

design, the boiler is more restrictive than a

conventional boiler, thus greater

consideration must be given to the

capabilities of the circulating pump(s) in

the primary-loop (including the Indirect

Hot Water heater loop-pump).

The following is a listing of the

recommended circulators.

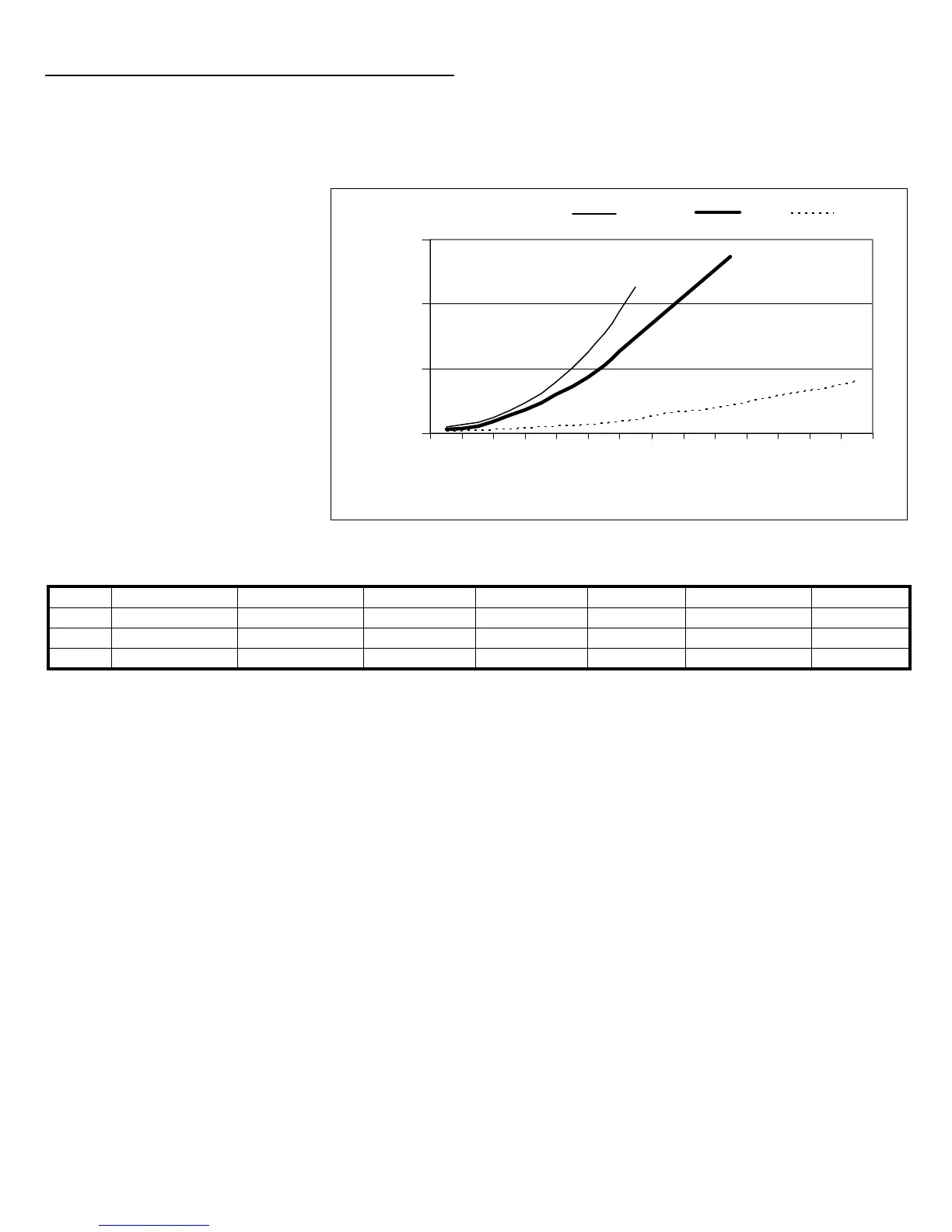

Model

Restriction

Head Loss

Recommended

Pipe Size

Minimum

Flow (us

GPM)

Max. Temp.

Rise

Minimum Primary Pump Size

B&G Grundfos Taco

100 7’ at 6 GPM 1” 4.5

45°F

NRF-22* UP 15-58* 008*

150 7’ at 6 GPM 1” 6

45°F

PL-30 UP 26-64 009**

200 10’ at 8 GPM 1-1/4” 8

45°F

PL-36 UP 26-99 0011

400 10’ at 20 GPM 1-1/2” 13

57°F

PL-36 UP 26-99 0011***

Notes:

*Must use at least minimum pump size specified for Ti150 if installation requires the use of a flow switch.

**The Taco 009 circulator will flow more through the Ti100-150 boilers than the Taco 0010 circulator.

***Recommend using a Taco 0013 for indirect circulator on Ti400.

Relief Valve: A 30PSI Relief Valve is provided with the system, and it is to be mounted as shown in the diagram. Ensure that the

discharge of the pressure relief is piped to a location were steam or water won’t cause personal injury or appliance and property damage.

The Ti100-150ASME and Ti400 have a maximum operating pressure of 80PSI (145PSI on some models, check the ASME plate affixed

to the heat exchanger), therefore a relief valve with a higher relief setting can be used.

Boiler Venting: Hot water boilers are designed to operate with airless water in the system. An Air Scoop, installed as shown in the

following diagrams, must be installed to remove air as it circulates through the boiler. It is recommended that an additional Air Scoop be

used in the secondary plumbing. If air continues to be a problem an air scrubber must be used (recommend Spirovent # VJR 100TM for

Ti100-150, VJR 125TM for Ti200, and VJR 150TM for Ti400. Use a minimum 1-1/4” primary-loop plumbing with model VJR 125TM

and 1-1/2” primary-loop plumbing with model VJR 150TM).

Loading...

Loading...