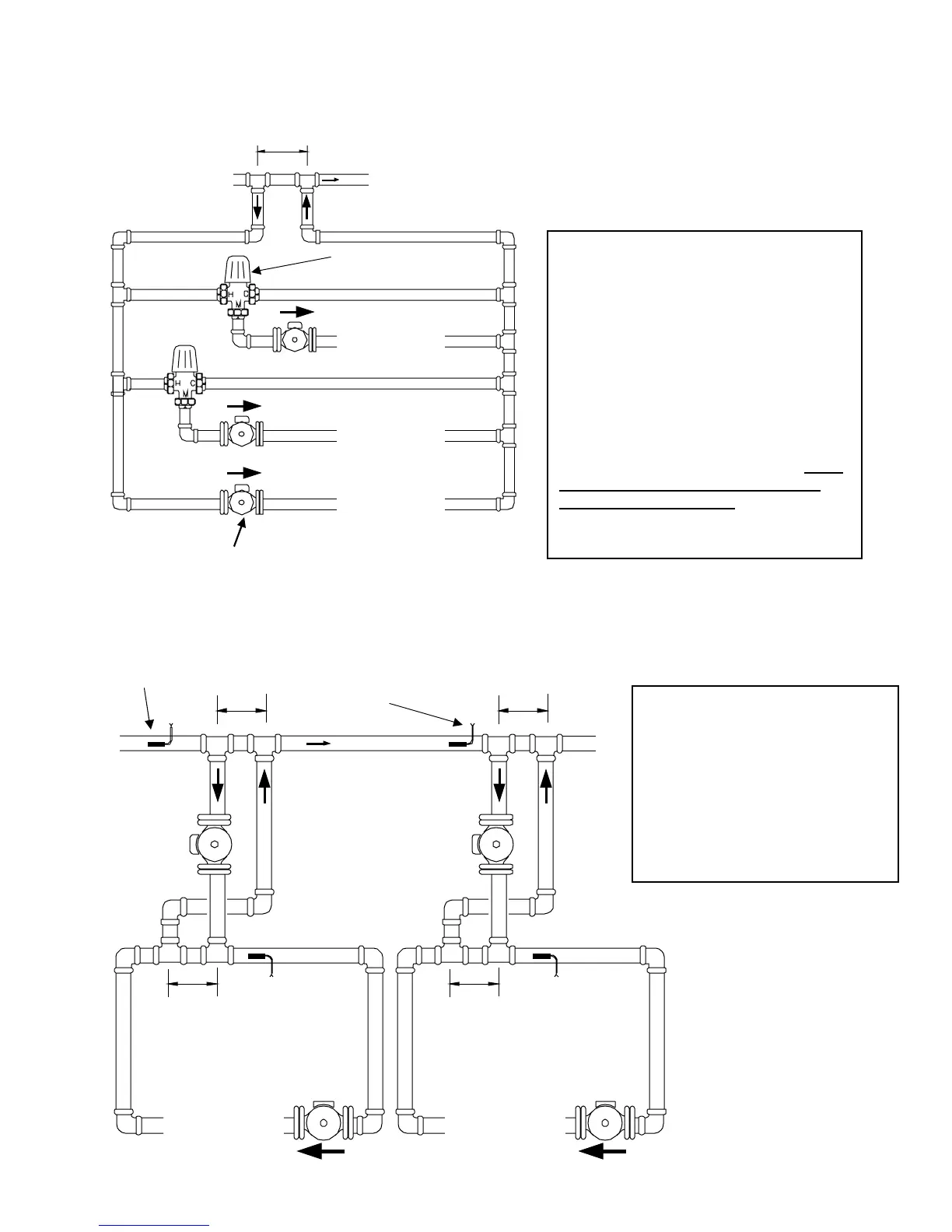

17

Zone 3

High Temp.

Tempering valve

Zone 2

Med. Temp.

Zone 1

Low Temp.

Pumps sized to each

zones flow and head

requirements

Primary

Loo

Max. 12” apart

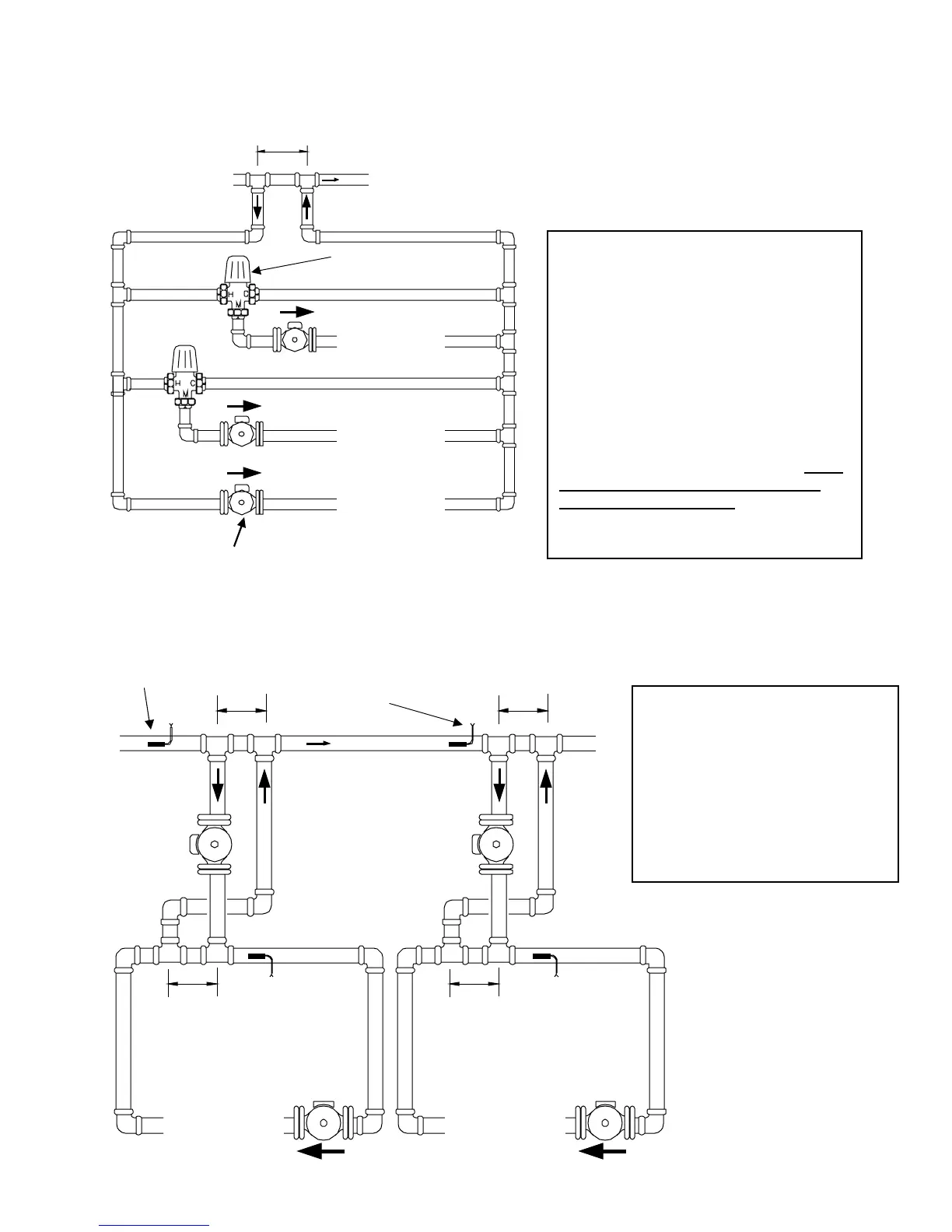

6.2.3 Multiple Zones with Different Temperatures

Using pumps and tempering valves

Using Injection pumps

Loop 1

High

Temp.

Injection

Pump

Primar

loo

Max. 12” apart

Max. 12” apart

Max. 12”

apart

Max. 12”

a

art

Loop 2

Low

Temp.

Injection

Pump

Loop Pumps sized to each loops flow and head requirements

Boiler sensor #2

(Lo Temp.)

Boiler sensor #1

(Hi Temp.)

Mix sensor #1

(Hi Temp.)

Mix sensor #2

Lo Temp.)

See figure

7.2.3 “Multiple Zones using pumps,

and pump controller”

By setting the tempering valves to different

settings, multiple temperatures can be

obtained.

Installer may require throttling and check

valves to correctly regulate the system.

Other configurations may work, but under

no circumstances can a mixing valve be

placed in the primary loop as overheating

of the boiler could occur.

See figure

7.2.4 “Multiple temperature Zones

using injection pump”

Installer may require throttling and

check valves to correctly regulate

the system

Loading...

Loading...