13

Part 2 - Operating Instructions

O. During Operation

1. Check for Gas Leaks

Frequently check the gas pipe and connections for leaks with a

soapy solution. Gas is leaking if air bubbles appear during the test.

Close the gas supply valve and call your gas supplier for inspection.

2. Check Exhaust Vent and Intake Pipe for Proper Ventilation

Ensure there is sufficient ventilation while operating the boiler.

Improper ventilation could result in premature boiler failure. Such

failures ARE NOT covered by boiler warranty.

3. Burn Warning

Take caution when inspecting the boiler and its internal

components, exhaust vent, and/or water pipes. These components

can get extremely hot during operation.

4. Combustibles and Flammable Material Warning

Do not store combustibles or flammable materials in the vicinity of

this boiler. Do not hang anything from the exhaust pipe.

5. Check for Water Leaks

• Do not attempt to clean the heating system. Call a qualified

service technician for service.

• Immediately call a qualified service technician if you notice any

leaks. Leaks in boiler or piping must be repaired at once.

P. General Cautionary Statements

The boiler is protected from malfunctioning by means of internal

checks performed by the electronic microprocessor PCB, which stops

the boiler from operating if necessary. In the event of the boiler being

shut off in this manner, a code appears on the display which refers to

the type of shut-off and the reason behind it.

There are two types of shut-off:

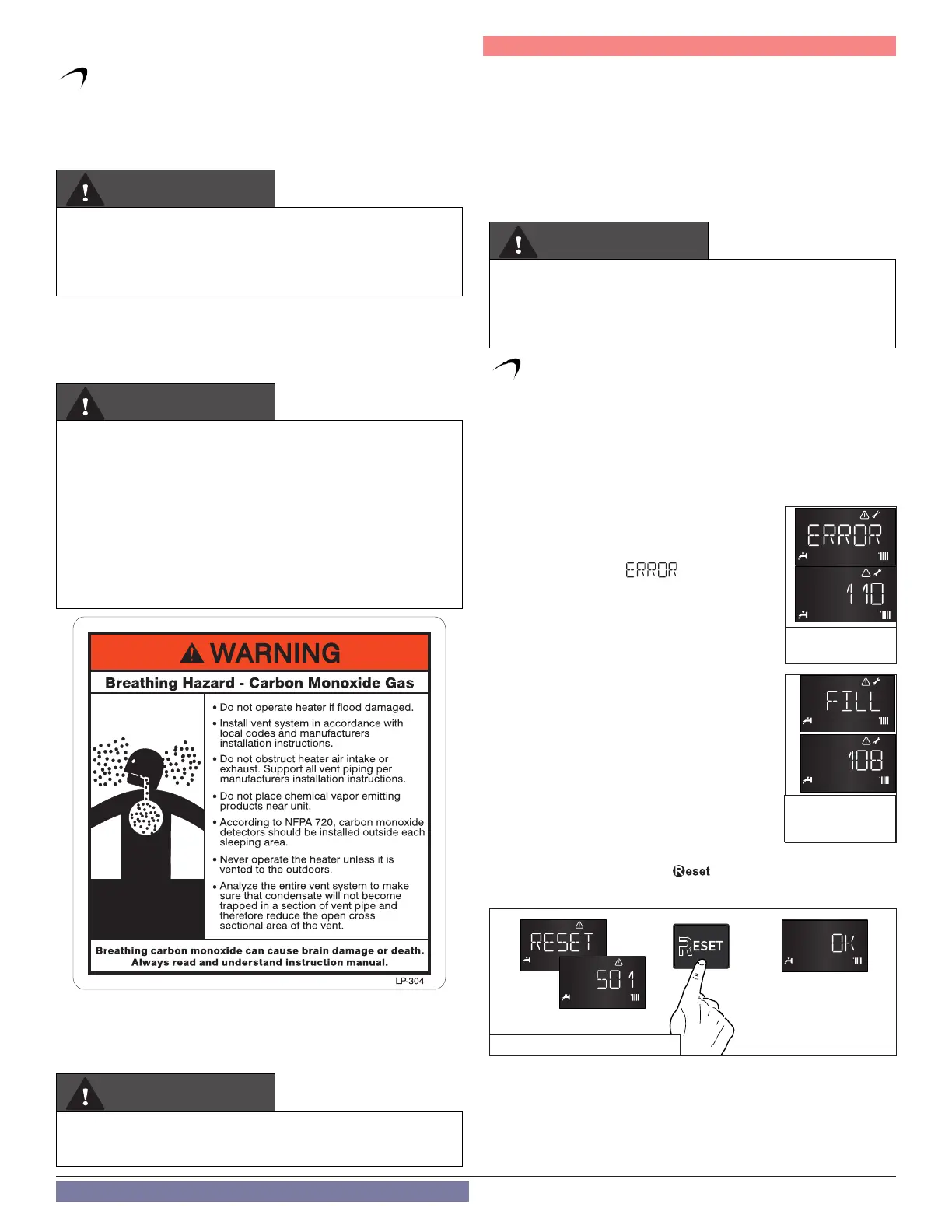

1. Blocking Error

A blocking error means the boiler will restart

automatically as soon as the problem which

caused the error clears or is removed; the error

is indicated by the « » symbol which

appears on the display followed by the error code.

For example, if the boiler indicates a 110 error

code, the error will clear automatically when the

CH temperature decreases. The boiler will restart

and operate normally.

NOTE: Contact a qualified service technician if the

error continues to occur.

In the event of Error 108 - Shut-off due to

insufficient water pressure inside the heating

circuit - turn the boiler off. Turn the external

electric power to the OFF position. Shut off the

main gas valve and contact a qualified service

technician to check for any leaks of water.

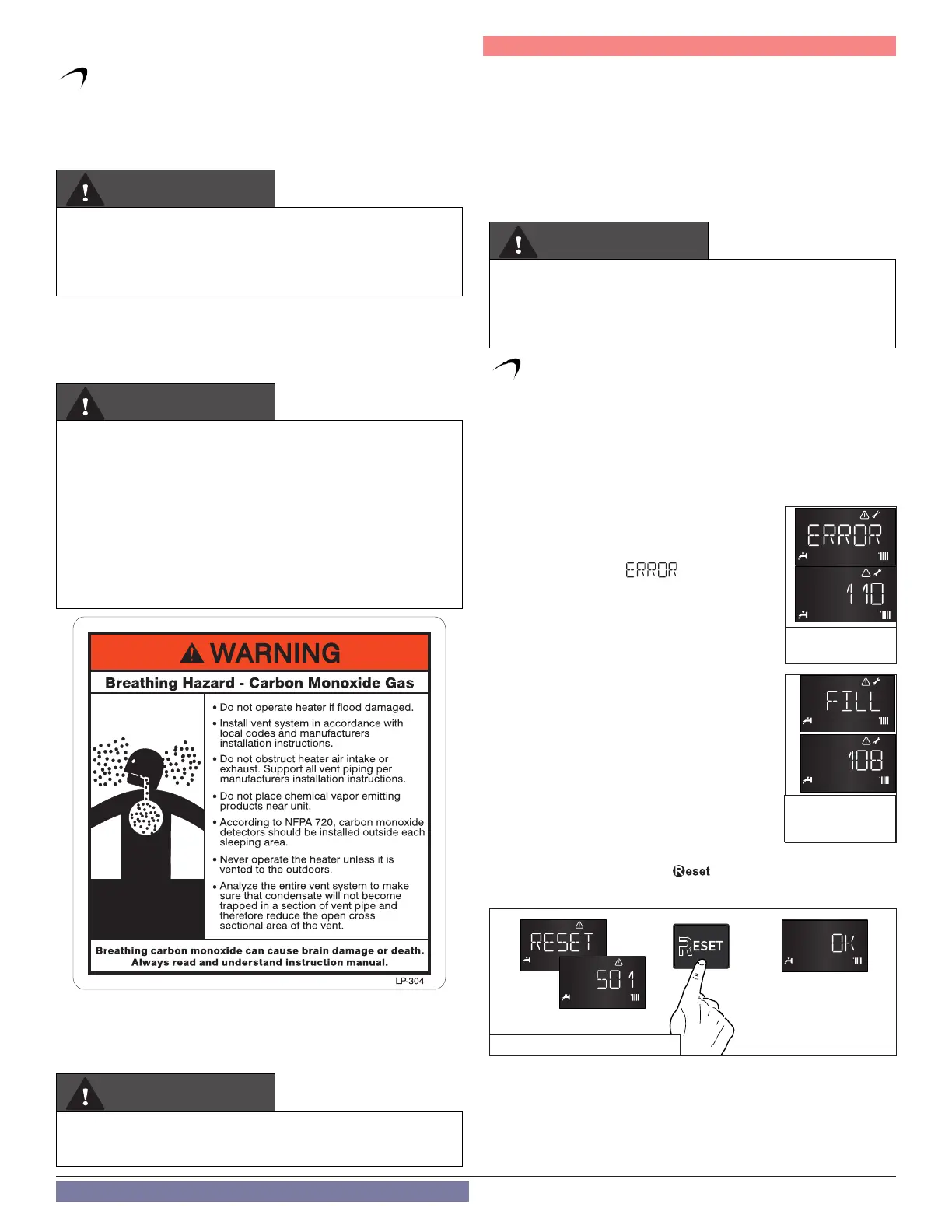

2. Lockout Error

A lockout error means the boiler does not return to operation after the

error condition goes away. The button must be pressed on the

control panel to restore boiler operation.

If the error condition occurs often contact a qualified service technician.

WARNING

WARNING

WARNING

After any repair of the gas pipeline or replacement of the gas

regulator, call a qualified service technician to observe the installation

and replacement before restoring power to the boiler. Failure to do

so could result in a fire or explosion, substantial property damage,

severe personal injury, or death.

DO NOT use this boiler for any purposes other than those specifically

described by NTI (to provide central heating and domestic hot water).

Using this boiler for unapproved purposes WILL VOID the warranty,

and could result in substantial property damage, serious personal

injury, or death.

Exhaust gas entering the living space can cause carbon monoxide

poisoning. If exhaust gas should leak into the living space:

• Shut down the boiler.

• Close the gas valve.

• Open windows for ventilation.

• Ensure the CO detectors are operating properly.

Immediately call a qualied service technician to inspect the boiler

and exhaust vent pipe. Any damages to the exhaust vent pipe should

be repaired immediately. Failure to do so could result in a re or

explosion, substantial property damage, severe personal injury, or

death.

WARNING

Storing flammable or combustible materials near this boiler could

result in a fire or explosion, substantial property damage, severe

personal injury, or death.

Figure 10 - Blocking

Error Example

Figure 11 -

Shut-Off

Error for Low Water

Pressure

Figure 12 - Lockout Error Example

Loading...

Loading...