5

Part 1 - Product and Safety Information

B. Primary Water

• Do not attempt to clean the heating system. Call a qualified

service technician for service.

• If you notice any leaks, immediately call a qualified service

technician. Leaks in boiler or piping must be repaired at once.

Closed loops that use glycol as heat transfer fluid must be serviced

periodically. Glycol can break down over time, become acidic, and

attack gaskets and seals in boilers. This can result in property damage,

severe personal injury, or death.

Each glycol manufacturer has different recommendations for

testing and replacement. Do not test glycol quality yourself. Have

your qualified service technician check glycol quality during annual

servicing. If you are unsure when your glycol was last tested, call a

qualified service technician to test and replace glycol, if necessary.

C. Freeze Protection

DANGER

WARNING

DO NOT shut off the boiler for long periods of time during potentially

freezing conditions. If the boiler must be shut off during potentially

freezing conditions (is not to be used for an extended period of time),

shut down the system and drain it of water. Shut off the gas and cold

water supply valves.

Ensure exposed water pipes are thermally insulated to prevent

damage due to freezing conditions. If the boiler is not to be used for

an extended period of time during freezing conditions, shut down

the system and completely drain the boiler.

If the water pipes should freeze, thaw the pipes with a hair dryer or

other electric heating device. If this does not work, call a qualified

service technician.

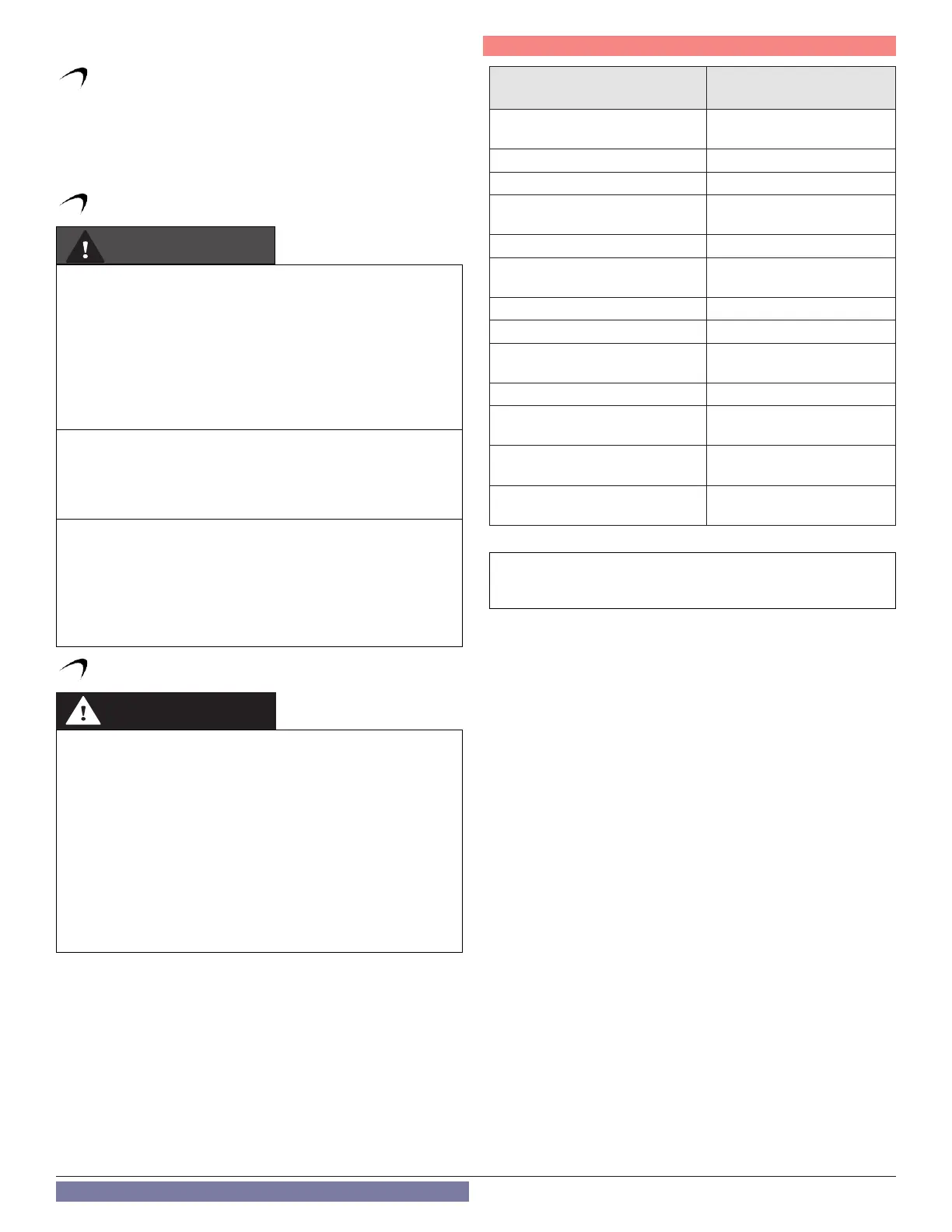

Do not operate the boiler if its combustion air intake is located in or

near one of the areas or in the vicinity of products listed in Table 1.

These areas will always contain hazardous contaminants that can

form strong acids while passing through the burner and vent

system. These acids will corrode the boiler’s heat exchanger, burner

components and vent system, resulting in flue gas spillage and/

or water leakage, possible substantial property damage, severe

personal injury, or death. If the boiler combustion air intake is located

in any area likely to cause or contain contamination, or if products

which would contaminate the air cannot be removed, the intake

must be re-piped and terminated to another location.

DO NOT re-pipe ventilation system on your own. Call a qualified

service provider for assistance.

Products to Avoid

Areas Likely to Have

Contaminants

Spray cans containing

fluorocarbons

Dry cleaning / laundry areas

and establishments

Permanent wave solutions Swimming pools

Chlorinated waxes / cleaners Metal fabrication plants

Chlorine-based swimming pool

chemicals

Beauty shops

Calcium chloride used for thawing Refrigeration repair shops

Sodium chloride used for water

softening

Photo processing plants

Refrigerant leaks Auto body shops

Paint or varnish removers Plastic manufacturing plants

Hydrochloric or Muriatic acid

Furniture refinishing areas

and establishments

Cements and glues New building construction

Antistatic fabric softeners used in

clothes dryers

Remodeling areas

Chlorine-type bleaches, laundry

detergents, and cleaning solvents

Garages and workshops

Adhesives used to fasten building

products

Table 1 - Products and Areas Likely to Have Contaminants

NOTE: DAMAGE TO THE Boiler CAUSED BY EXPOSURE TO

CORROSIVE VAPORS IS NOT COVERED BY WARRANTY.

(Refer to the limited warranty for complete terms and conditions.)

D. Combustion Air Contamination Prevention

Loading...

Loading...