60

420012001500 - 03182024 - Rev. 04

WARNING

WARNING

NOTICE

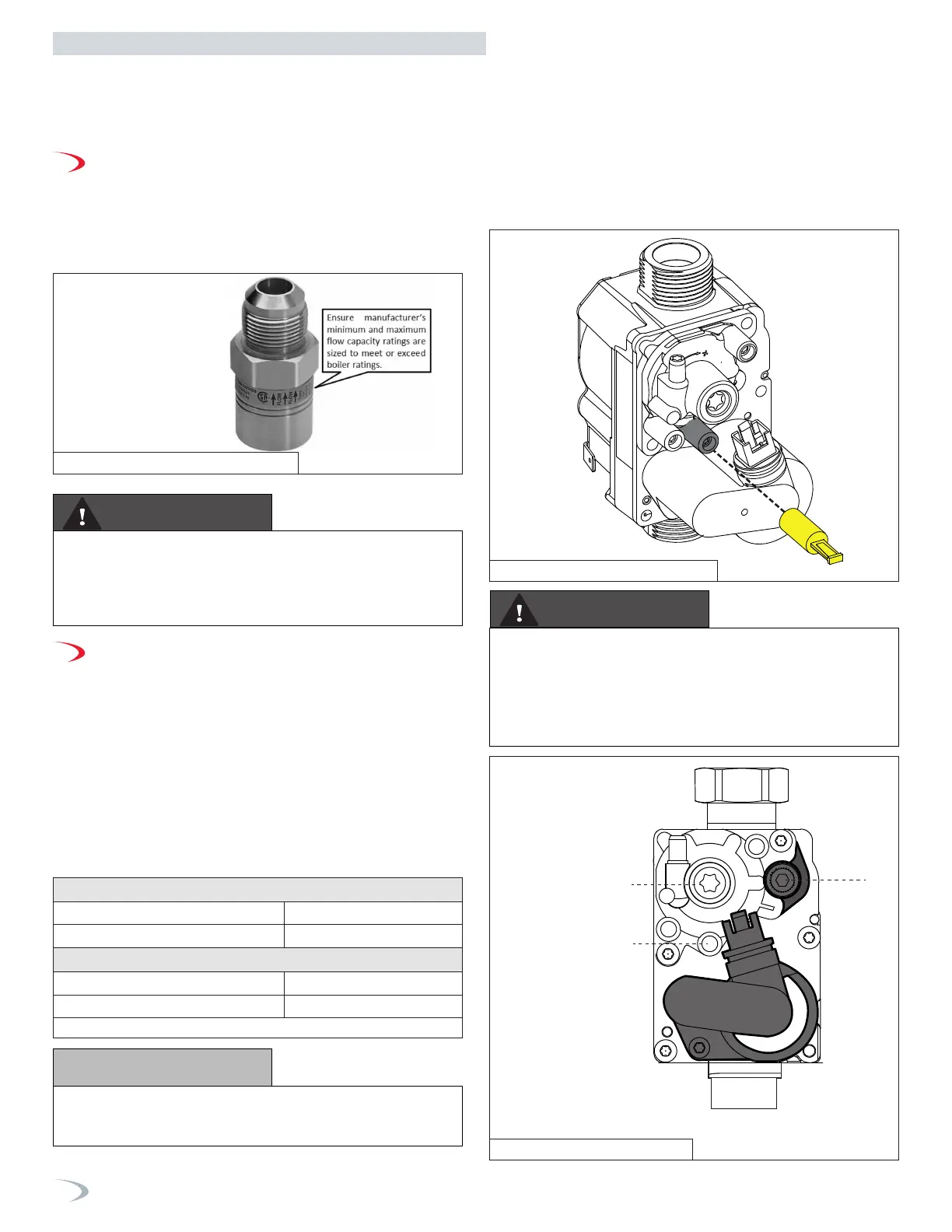

C. Additional Precaution for Excess Flow

Valve (EFV)

If an excess flow valve (EFV) is in the gas line, check the manufacturer’s

minimum and maximum flow capacity ratings. An improperly sized

EFV will not allow for a full flow of gas to the boiler and will cause the

boiler to malfunction. See Figure 73.

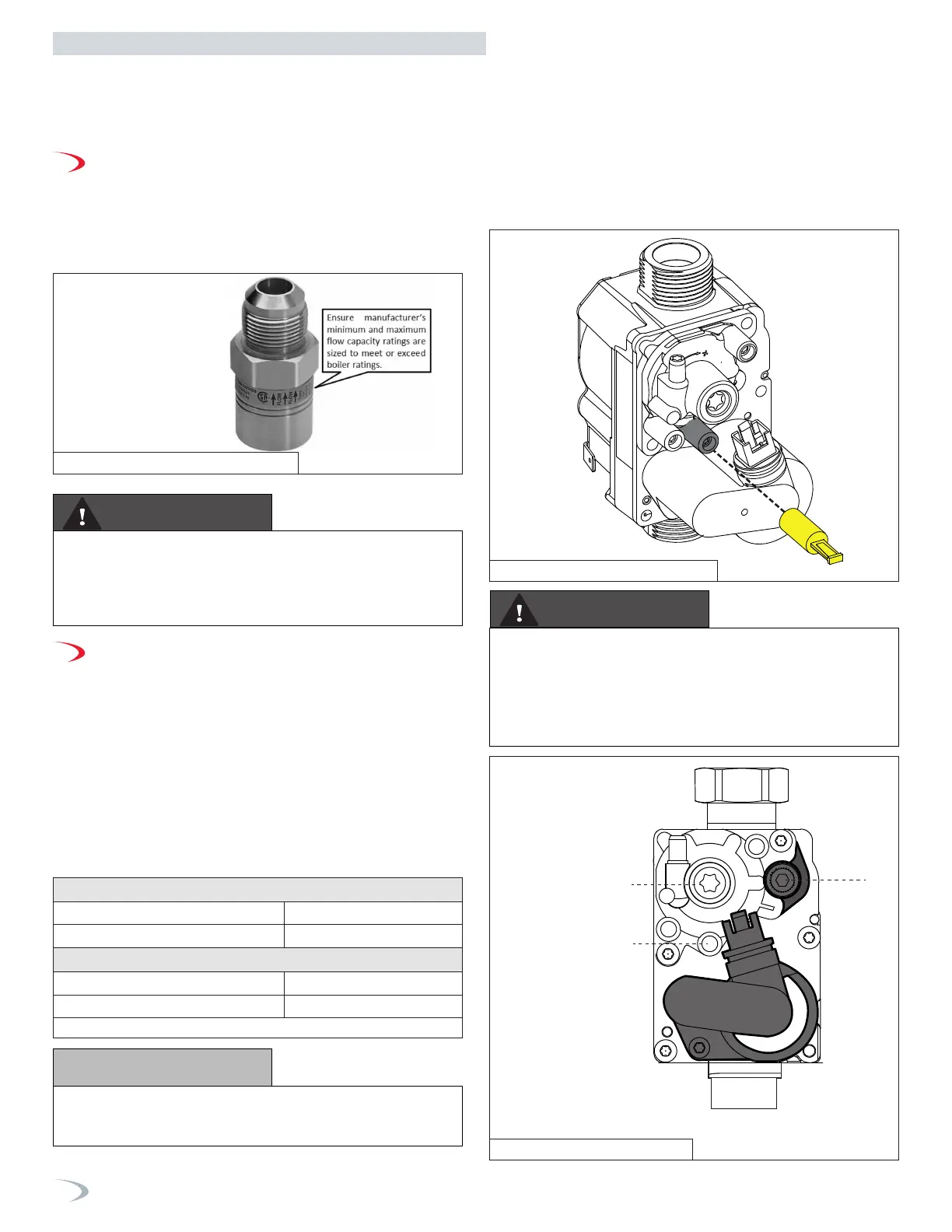

D. Checking Gas Pressure at the Boiler for

Proper Operation

NOTE: Refer to Figure 74 when checking gas pressure. Loosen the

bolts before checking the gas inlet pressure.

1. The boiler and its individual shutoff valve must be disconnected

from the gas supply piping system during any pressure testing of

the system at test pressures greater than ½ psi (3.5 kPa).

2. The boiler must be isolated from the gas supply piping system by

closing its individual manual shutoff valve during any pressure

testing of the gas supply piping system at test pressures equal to or

less than ½ psi (3.5 kPa).

The minimum and maximum inlet gas line pressures must meet the

requirements shown in Table 23.

To check inlet gas pressure:

1. Remove yellow cap from line pressure test point. See Figure 74.

2. Unscrew “P in” screw.

3. Connect the manometer to the test point.

4. Check the inlet gas pressure.

5. Disconnect the manometer from the test point.

6. Tighten the “P in” screw (1 N/m).

7. Check for and repair any gas leaks.

8. Replace the yellow cap.

Natural Gas

Minimum Pressure 3.5” WC

Maximum Pressure 10.5”WC

LP Gas

Minimum Pressure 8” WC

Maximum Pressure 13”WC

4

2

1

IN

Gas Inlet

1. Line pressure Test point

2. OFFSET Adjustment Screw

4. Throttle Adjustment Screw

Figure 72 - Excess Flow Valve (EFV)

Figure 73 - Remove Yellow Cap

Figure 74 - Gas Valve Detail

When performing a pressure test on the gas line pipng, be sure the

boiler is disconnected or isolated if the test pressure is expected to

exceed 1/2 PSI (14” WC), as damage to the gas valve could occur.

Such damage could result in fire, property damage, serious personal

injury, or death.

DO NOT REMOVE OR ATTEMPT TO MAKE AN

ADJUSTMENT TO SCREWS 2 and 4 WITHOUT A

CALIBRATED COMBUSTION ANALYZER. DOING SO

COULD RESULT IN FIRE, PROPERTY DAMAGE, SERIOUS

PERSONAL INJURY, OR DEATH.

Do not fire (operate) the boiler until all connections have been

completed and the heat exchanger is filled with water. Doing so will

damage the boiler and void the warranty.

8. Leak test the gas line pipe before placing the boiler in operation.

Only use approved leak detector liquid solutions to check for leaks.

9. Do not operate the boiler until all connections have been

completed and the heat exchanger is filled with water.

Part 8 - Gas Connections

Table 23 - Gas Pressure Requirements

Loading...

Loading...