4307 & 4310 Blower | 25

The time intervals between the various maintenance procedures depends

greatly on such factors as:

• Type of product being pumped

• Actual pumping time

• Idle equipment (periods of non use)

• Set up perimeters (rpm and working vacuum and pressure)

• Working climate and conditions

It is therefore up to the operator to adjust the following schedule accordingly.

Lubrication:

Unlike a typical rotary vane vacuum pump, the Challenger Series 4307 high

vacuum blower does not use oil in it’s operation. Therefore it is important to

periodically lubricate the internal parts in the blower to keep it free of rust and

corrosion, which can cause seizing or catastrophic failure.

Main Pump Housing – Diesel ush;

At least weekly.

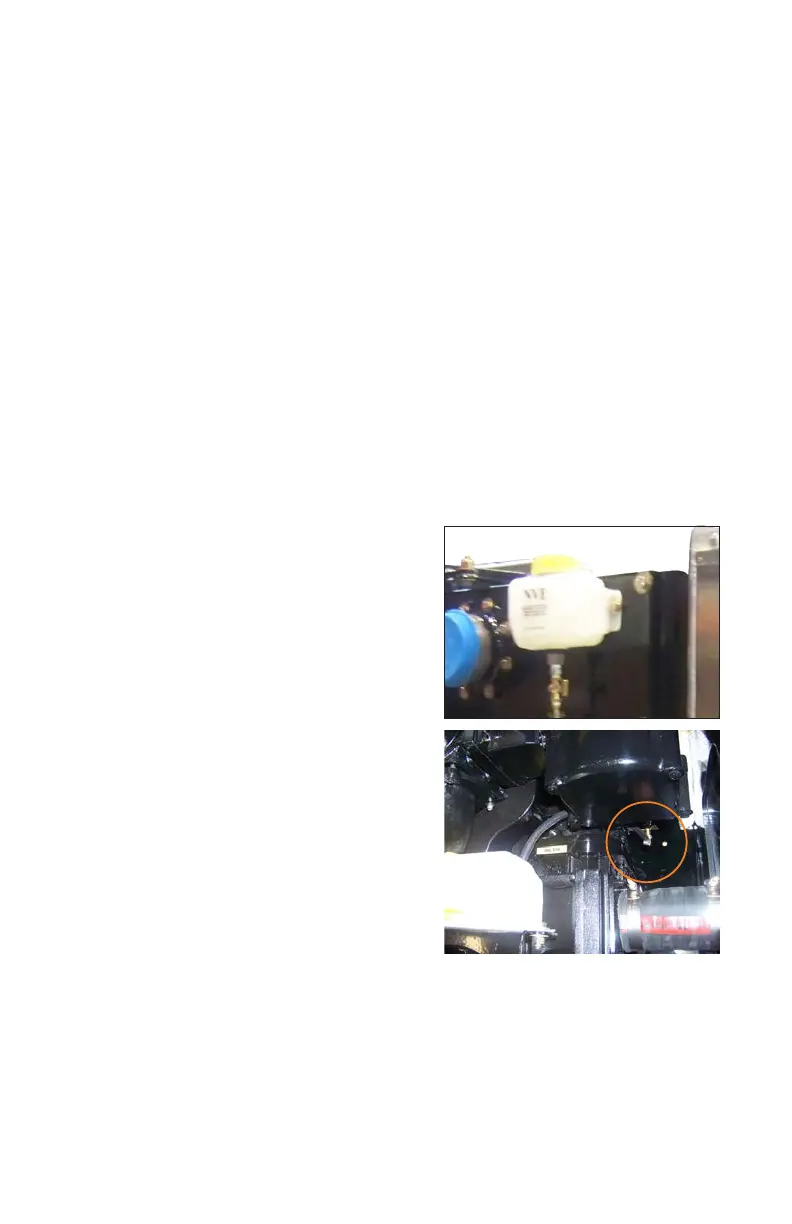

• Your blower comes standard with a die-

sel ush kit installed. This is used to in-

troduce small amounts of diesel into the

machine to clean out debris and inhibit

rust. Note this procedure is also followed

daily in cold climates to help keep any

moisture that may be in the blower from

freezing up.

• Make sure the reservoir contains diesel

fuel.

• While the blower is running at it’s lowest

rpm setting with the vacuum/pressure

change over valve in the neutral position,

open the brass valve at the base of the

diesel ush reservoir and close it after 2

seconds.

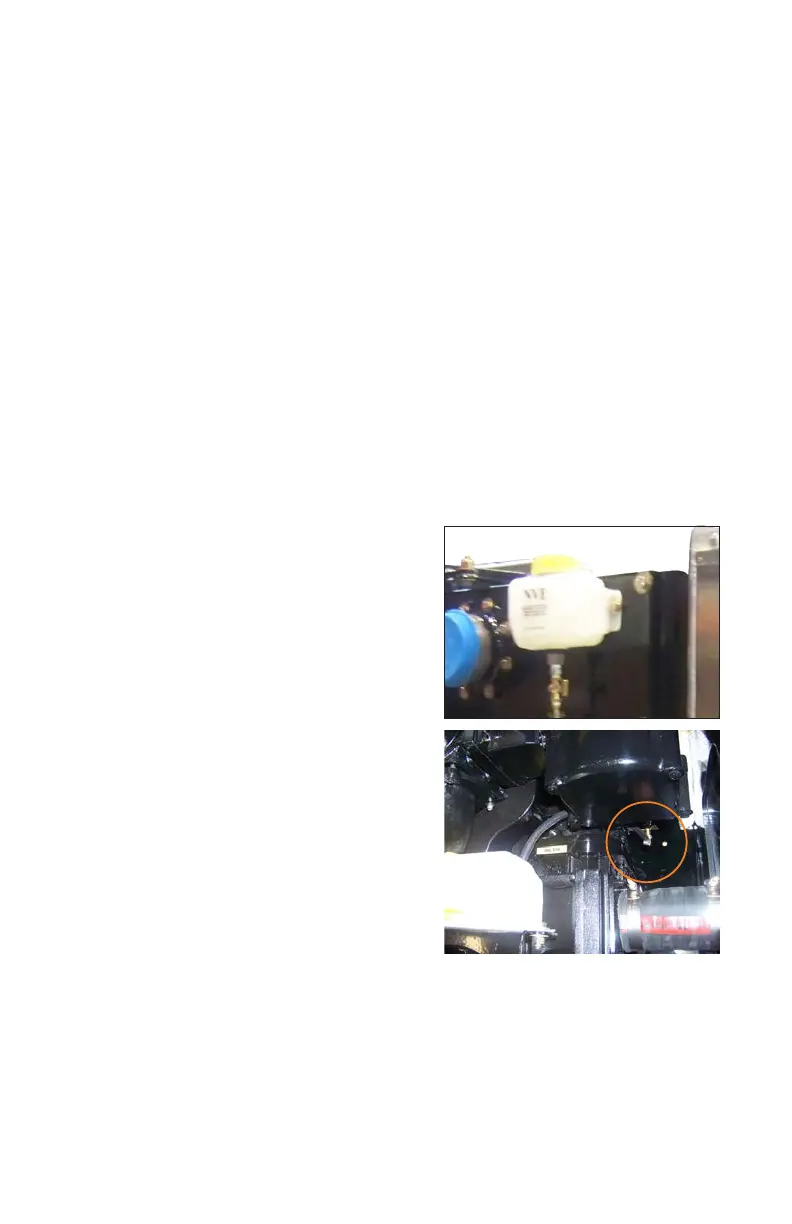

• In instances where there is signicant water or product in the blower

this process can be repeated as necessary. In that case the drains

in the bottom of the silencers should be left open until the process is

complete.

4307 Blower Maintenance

nvesalesrep.com | 888.814.9191

Loading...

Loading...