Centers – Installing and Removing

Headstock

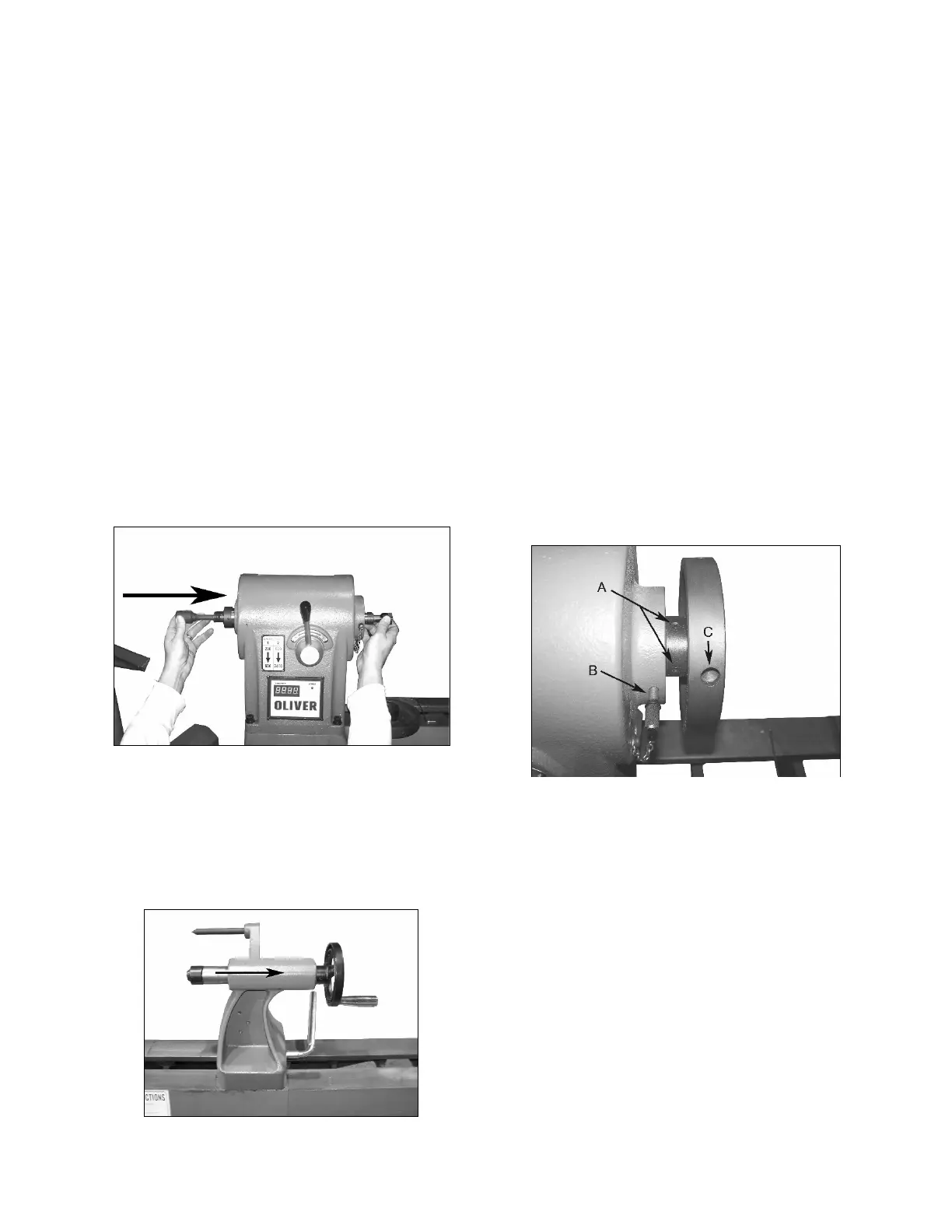

1. T

o install a spur center in the headstock t

he

c

enter should first be mounted to your

workpiece and both should be inserted into

the headstock at the same time. Make sur

e

both the spur center shaft and the headstock

spindle mating surfaces are clean and free of

debris.

W

arning: Do not drive the workpiece into the

spur center while it is in the headstock or

bearing failure will occur.

2. T

o remove the spur center, first remove the

workpiece from the lathe, insert the knockout

rod through the hole in the outboard spindle

then firmly tap the end of the spur center

shaft. See Figure 18a.

N

ote: Make sure to hold onto the spur center

while knocking it out so as to prevent it from

falling on the floor and damaging it.

F

igure 18a

Tailstock

T

o remove the live center from the tailstock

simply turn the handwheel in order to retract the

tailstock spindle into the body as shown by the

arrow in Figure 18b.

F

igure 18b

Face Plates – Removal and Installation

Inboard

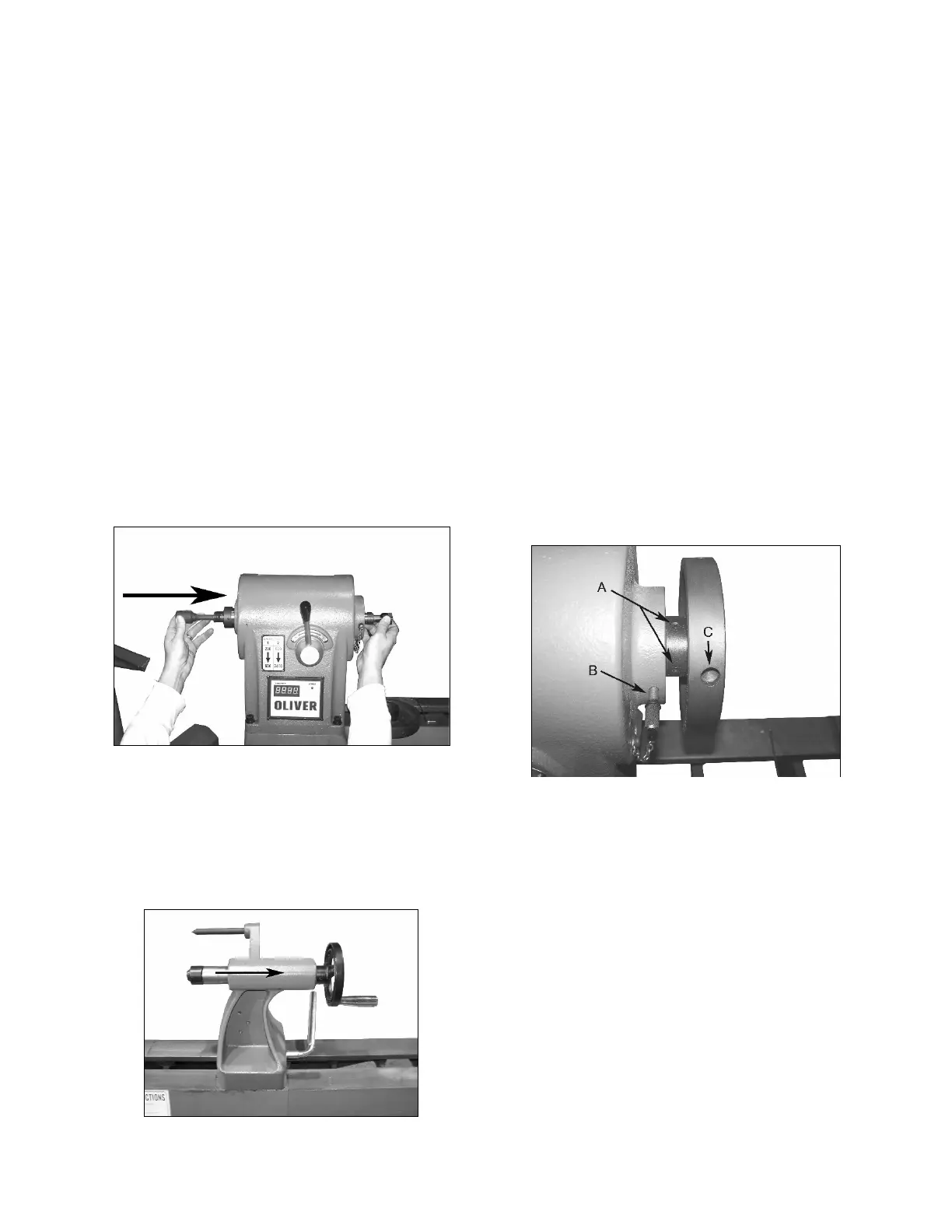

1. T

o remove the face plate first loosen the

two set screws ‘A’ of Figure 19. Insert the

indexing pin ‘B’ into one of the three

holes and screw it in until it fully engages

one of the indexing holes in the spindle.

You may have to turn the face plate by

hand until you can feel the pin engage

the hole. The spindle should now be

locked. The face plate can now be

unscrewed counterclockwise off the

spindle. If more leverage is needed

insert the knock out rod into hole ‘C’.

2. Use the reverse procedure to install the

face plate back onto the spindle.

N

ote: Do not use the knock out rod to

tighten the face plate or thread damage

can occur. Hand tighten only.

F

igure 19

Loading...

Loading...