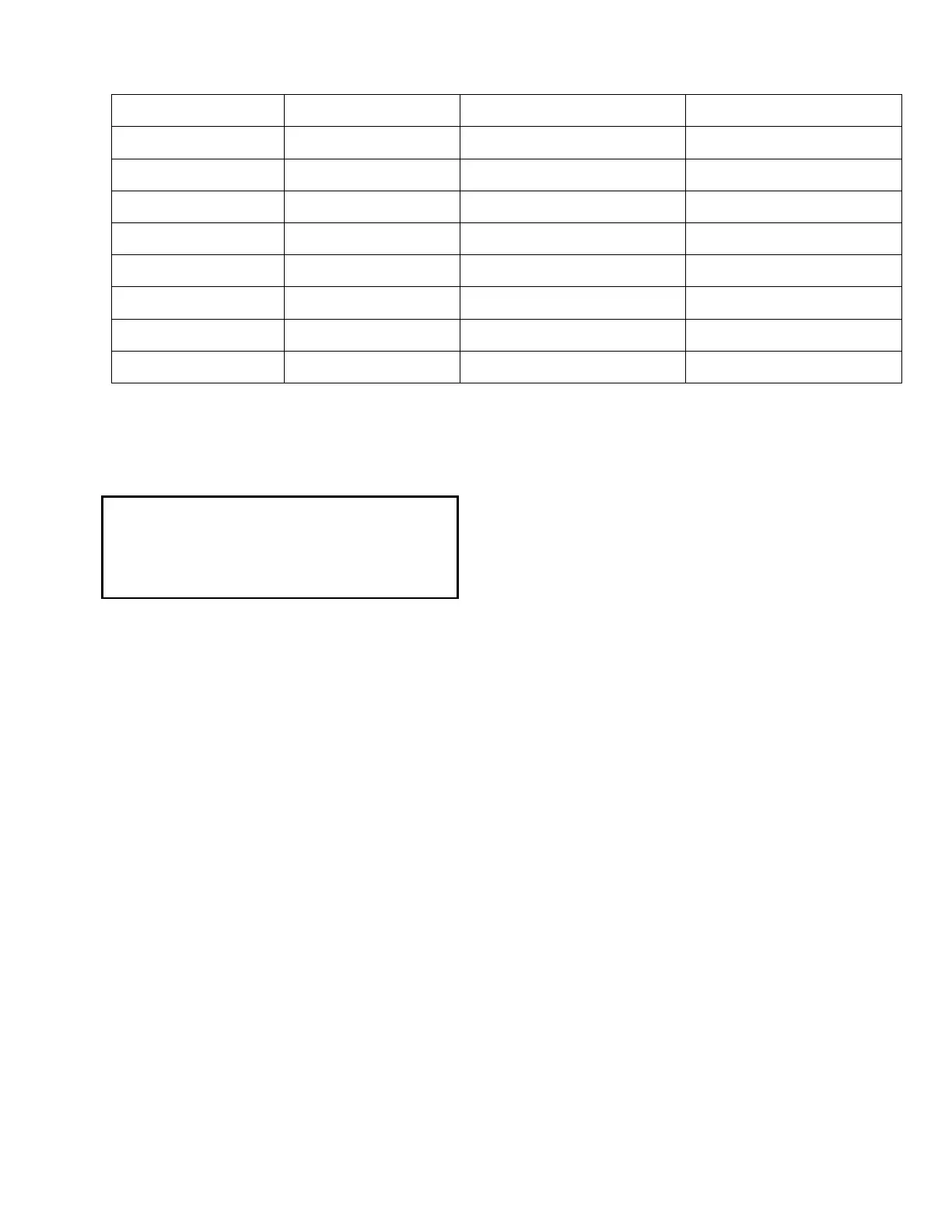

Recommended Lathe Speeds

Maintenance

WARNING!

Before doing maintenance on the lathe,

disconnect the lathe from its power source.

Failure to do so could result in serious injury!

Mai

ntenance on your Oliver lathe should be done at

periodic intervals to ensure that the machine is in

good working order. Inspection and maintenance

should be performed at least twice a year but more

often if the lathe receives constant use.

1. C

heck all fasteners to make sure they are tight

and check all adjustments that they are in order.

2. Clean and oil the late beds so that the headstock,

tailstock and tool support base will slide easily.

Clean any rust spots that may develop on the be

d

w

ith a commercial rust remover.

3. Use compressed air to blow out the interior of the

headstock in order to keep chips and sawdust

from accumulating on the belts and pulleys.

4. C

lean out the morse tapers on both the

headstock and tailstock. Commercially available

cleaners may be acquired form tool stores.

5. Check the drive belt for tightness. It should be

snug but not overly tight.

6. Use a mill file to remove any nicks or dings from

the tool rests.

7. Clean and lubricate the tailstock ram and locki

ng

m

echanism.

Loading...

Loading...