1-1 Cyclic Servo Assembly

Servo Swashplate (× 3)

Servo Arm (× 3)

Socket cap screw

M2x4mm ( × 3)

Ball Joint Screw - L4.65 (× 3)

M2 Nylon locknut (× 3)

Servo Arm (× 3)

Socket cap screw

M2x4mm ( × 3)

Ball Joint Screw - L4.65 (× 3)

M2 Nylon locknut (× 3)

Socket cap screw

M2x4mm ( × 6)

M4X-101

M4X-102

Servo Rack ( × 1)

Servo Rack ( × 1)

Socket cap screw

M2x4mm ( × 6)

1-2 Servo Rack Assembly

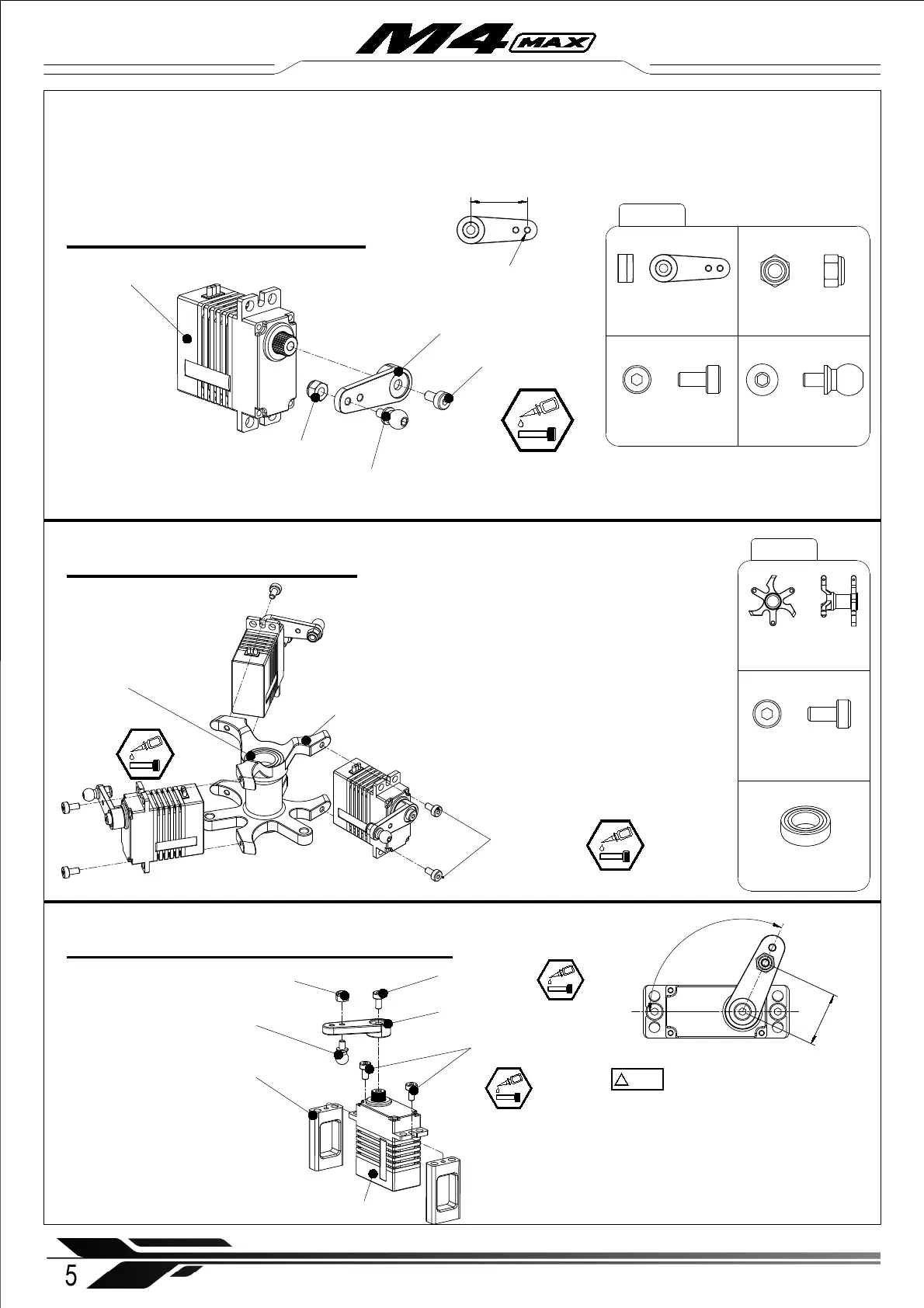

1-3 Tail servo (Micro servo ) assembly

※

The ball joint screw should be screwed

into the outer hole of the servo arm.

5

WWW.OMPHOBBY.COM

Installation steps 安装步骤

Bearing ∅ 8x ∅ 14x4mm ( × 2)

Bearing ∅ 8x ∅ 14x4mm ( × 2)

※ Note: All servo wires shou ld exit the servo rack

in one position , which should be aligned with the

rear of the frame .

Partially pre-assembled parts are loosely screwed together without thread locker/glue

Recommendation: Loctite 243 for screws, Loctite 648 for bearing seats.

※ Note: In a crash, the servo arm spline can strip.

※ The servo wires can be wrapped around the

core of the servo rack to shorten them neatly.

16mm

115°

M2 Nylon locknut (× 1)

Tail servo (× 1)

Tail servo mount set (× 2)

Servo Arm (× 1)

Socket cap screw

M2x4mm ( × 2)

Socket cap screw

M2x4mm ( × 1)

Ball Joint Screw - L4.65 (× 1)

!

注意

CAUTION

The maximum height of the tail servo, including servo

arm, must be less than 40. 0mm. When the tail servo

arm is in the middle position, the angle relative to the

tail servo should be 115°, as shown above.

※ The M4 Max can be equipped with the

DS2312T micro servo, and the ball head screw

should be installed in the outer hole of the servo

arm. The manual will provide an illustrative

installation diagram for the mini servo, and the

installation method for the micro servo is the

same as that for the mini servo.

12.5mm

Loading...

Loading...