43

Determining PID Constants (AT, ST, Manual Setup) Section 3-8

3-8 Determining PID Constants (AT, ST, Manual Setup)

3-8-1 AT (Auto-tuning)

• When AT is executed, the optimum PID constants for the set point at that

time are set automatically. A method (called the limit cycle method) for

forcibly changing the manipulated variable and finding the characteristics

of the control object is employed.

• To execute AT, specify on (AT execute), and to cancel AT, specify off

(AT cancel).

• AT cannot be executed when control has stopped or during ON/OFF con-

trol.

• The results of AT are reflected in the “proportional band” (P), “integral

time” (I), and “derivative time” (D) parameters in the adjustment level.

AT Operations AT is started when the “AT execute/cancel” parameter is set to ON. During

execution, the “AT execute/cancel” parameter on the No. 1 display flashes.

When AT ends, the “AT execute/cancel” parameter turns OFF, and the No. 1

display stops flashing.

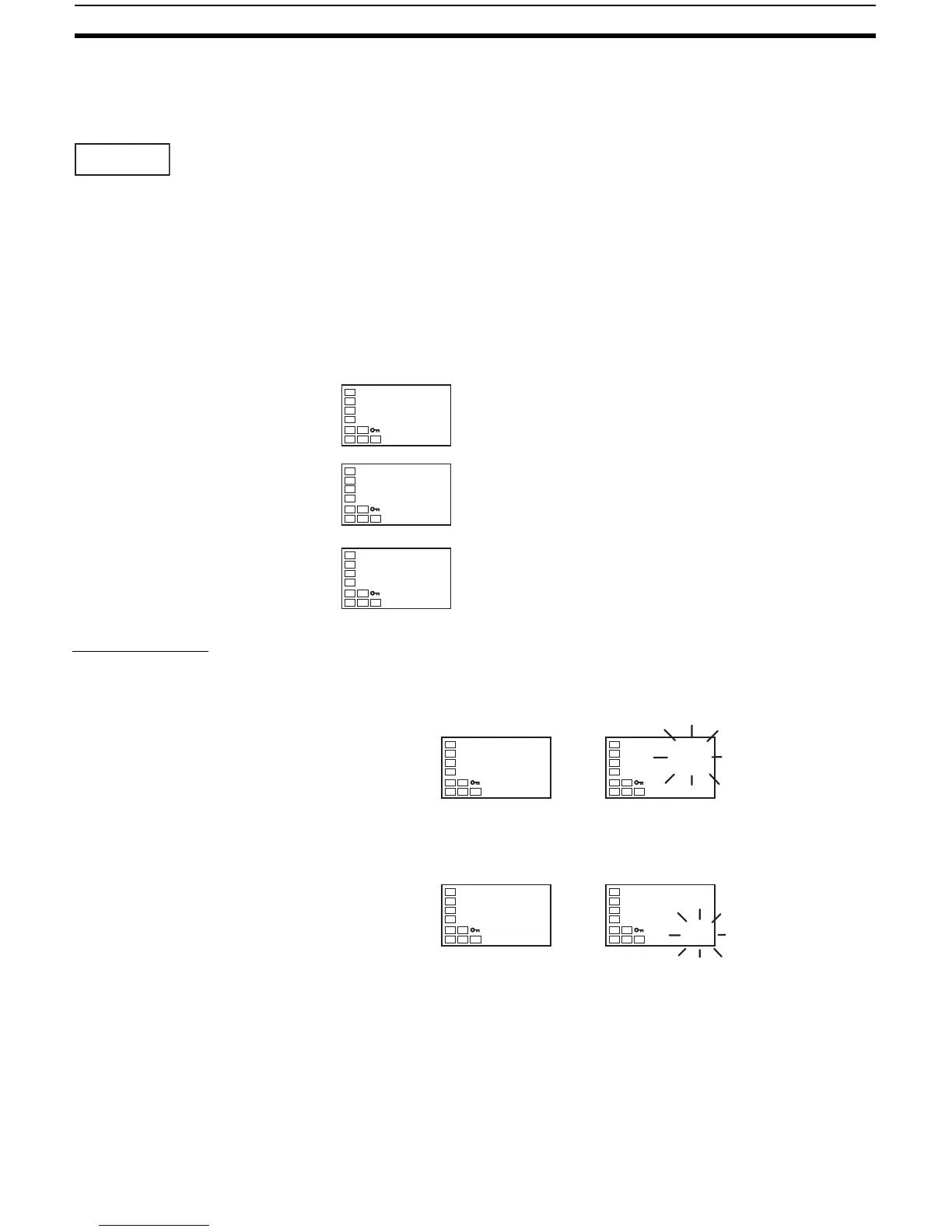

If you move to the operation level during AT execution, the No. 2 display

flashes to indicate that AT is being executed.

Only the “communications writing,” “RUN/STOP,” and “AT execution/cancel”

parameters can be changed during AT execution. Other parameters cannot

be changed.

at

i

233

C

p

(0

d

40

Adjustment Level

Proportional band

Integral time

Derivative time

at

off

at

on

AT execute/cancel

No. 1 displa

AT execution in progress

C

25

100

C

25

100

PV/SP

AT execution in progress

No. 2 display

Loading...

Loading...