E5jK-T

E5jK-T

39

Precautions

WARNING

Do not touch the terminals while the power is ON.

This may cause an electric shock.

General Precautions

Be

sure to observe these precautions to ensure safe use.

• Do

not use the product in places where explosive or flammable

gases

may be present.

•

Never disassemble, repair or modify the product.

• T

ighten the terminal screws properly

.

•

Use the specified size of solderless terminals for wiring.

•

Use the product within the rated supply voltage.

•

Use the product within the rated load.

• The life expectancy of the output relay varies considerably

according

to its switching capacity and operating conditions. Be

sure

to use the output relay within its rated load and electrical life

expectancy.

If

the output relay is used beyond its life expectancy

,

its

contacts may become fused or burned.

Correct Use

If you remove the Controller from its case, never touch nor apply

shock

to the electronic parts inside.

Do

not cover the E5

jK-T

. (Ensure suf

ficient space around the Con

-

troller

to allow heat radiation.)

Do not use the Controller in the following places:

• Places subject to icing, condensation, dust, corrosive gas

(especially

sulfide gas or ammonia gas).

•

Places subject vibration and large shocks.

•

Places subject to splashing liquid or oil atmosphere.

•

Places subject to intense temperature changes.

•

Places subject to heat radiation from a furnace.

Be sure to wire properly with correct polarity of terminals.

When

wiring input or output lines to the Controller

, keep the follow

-

ing

points in mind to reduce the influence from inductive noise:

• Allow adequate space between the high voltage/current power

lines

and the input/output lines.

• Avoid parallel or common wiring with high voltage sources and

power lines carrying large currents.

• Using

separating pipes, ducts, and shielded line is also useful

in

protecting

the Controller

, and its lines from inductive noise.

Cleaning: Do not use paint thinner or organic solvents. Use stan-

dard

grade alcohol to clean the product.

Use

a voltage (100 to 240 V

AC at 50/60 Hz, or 24 VDC). At power

ON, the prescribed voltage level must be attained within two

seconds.

Allow as much space as possible between the Controller and

devices that generate a powerful high frequency (high-frequency

welders, high-frequency sewing machines, etc.) or surge. These

devices

may cause malfunctions.

If

there is a large power-generating peripheral device and any of its

lines

near the Controller

, attach a surge suppressor or noise filter

to

the

device to stop the noise af

fecting the Controller system. In par

-

ticular,

motors, transformers, solenoids and magnetic coils have

an

inductance component, and therefore can generate very strong

noise.

When

mounting a noise filter on the

power supply to the Controller

,

be sure to first check the filter’s voltage and current capacity, and

then

mount the filter as close as possible to the Controller

.

Use within the following temperature and humidity ranges:

• T

emperature: –10

°

C to 55

°

C (with no icing or condensation)

Humidity: 35% to 85% (with no icing or condensation)

If the Controller is installed inside a control board, the ambient

temperature must be kept to under 55°C, including the

temperature

around the Controller

.

If

the Controller is subjected to heat radiation, use a fan to cool

the surface of the Controller to under 55

°C.

Store within the following temperature and humidity ranges:

• T

emperature: –25

°

C to 65

°

C (with no icing or condensation)

Humidity: 35% to 85% (with no icing or condensation)

Never place heavy objects on, or apply pressure to the Controller

that

may cause it to deform and deteriorate during use or storage.

A

void using the Controller in places near a radio, television set, or

wireless installing. These devices can cause radio disturbances

which adversely af

fect the performance of the Controller

.

Mounting

The dimensions of the Digital Controller conform to DIN 43700.

Recommended

panel thickness is 1

to 8 mm (1 to 5 mm for E5CK).

Mount

the Unit horizontally

.

Connection

To

reduce inductive noise influence, the lead wires connecting the

input

type to the Digital Controller must be separated from the power

lines

and load lines.

Use the specified compensating conductors for thermocouples.

Use lead wires having a small resistance for platinum resistance

thermometers.

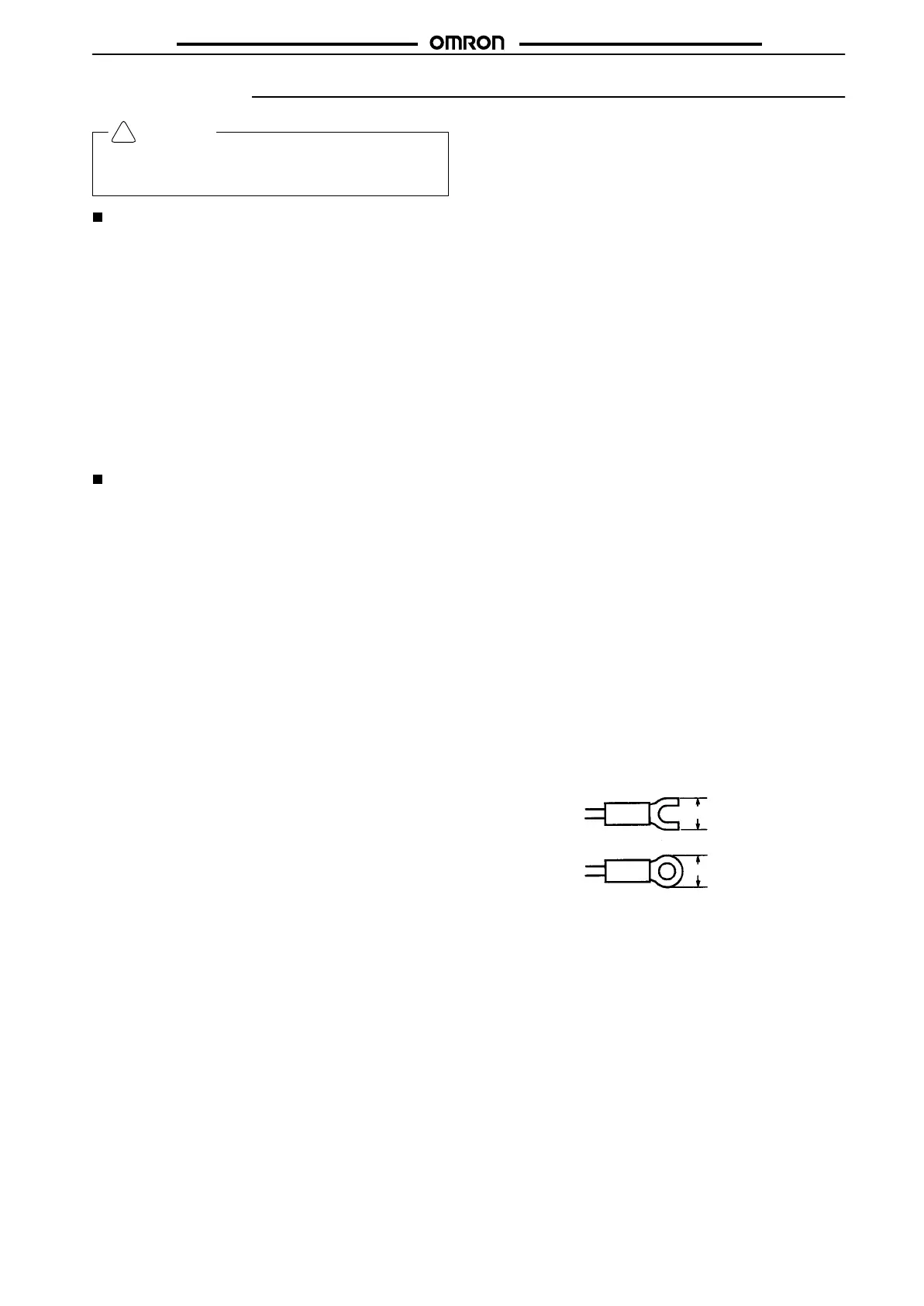

Connection Example

Wire

the terminals of the Unit using solderless terminals.

The

tightening torque applied to the terminal screws of the Unit must

be

approximately 0.78 N

S

m or 8 kgf

S cm.

Use the following type of solderless terminals for M3.5 screws.

7.2

mm max.

7.2 mm max.

!

Loading...

Loading...