F3SJ-A

18

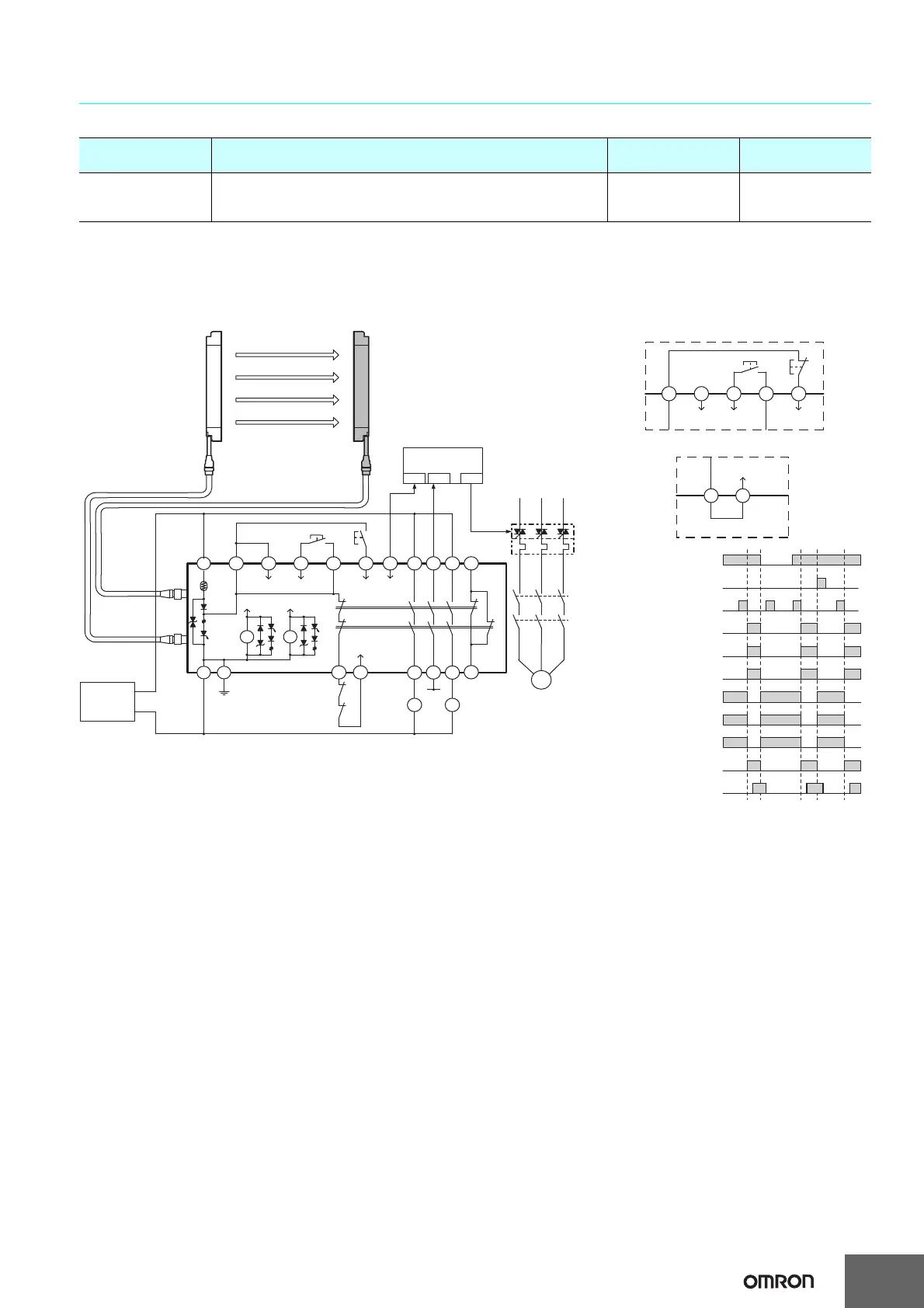

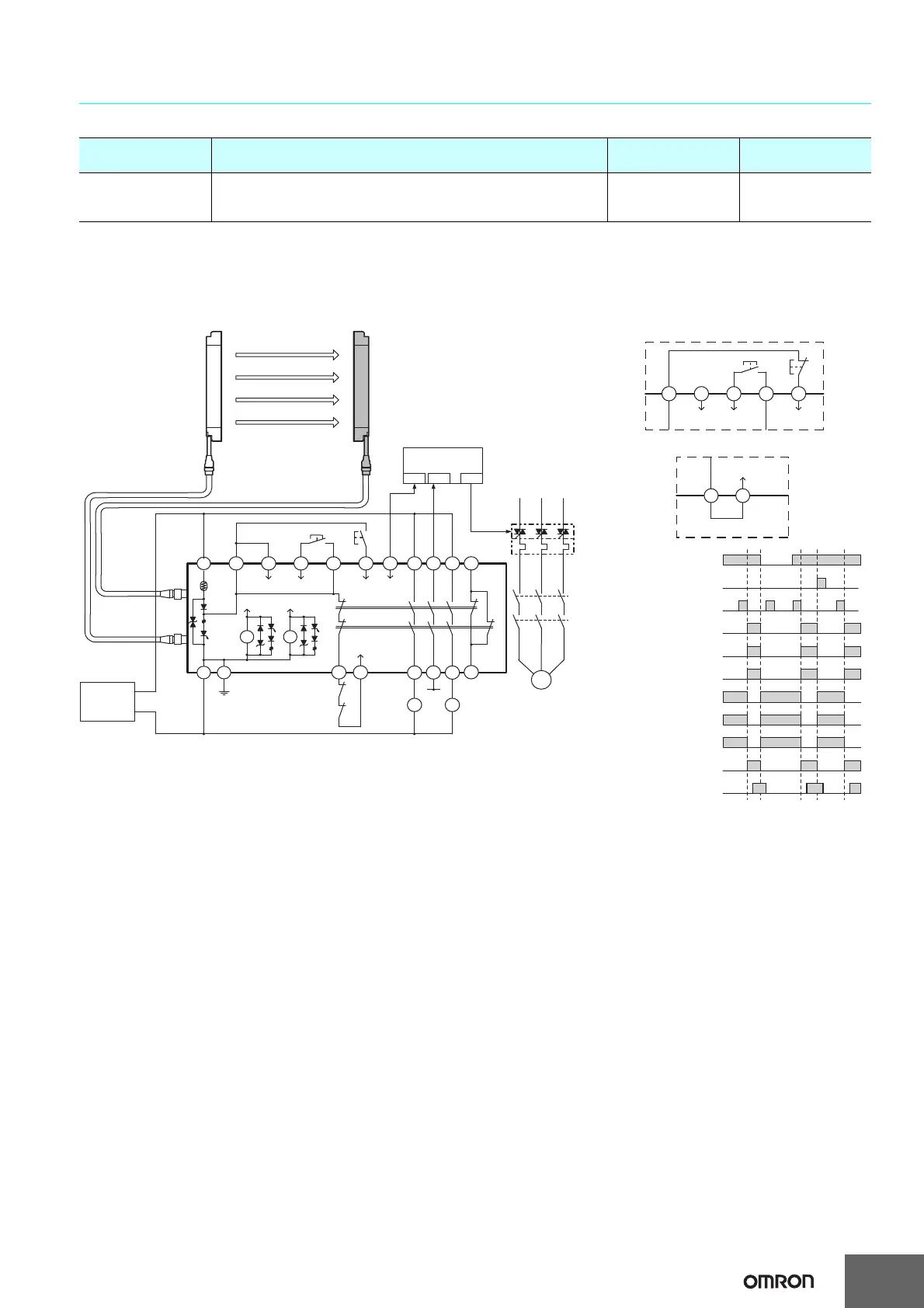

Wiring for connection with a controller F3SP-B1P

Note: The above PL is only the evaluation result of the example. The PL must be evaluated in an actual application by the customer after confirming

the usage conditions.

Application Overview

• The power supply to the motor M is turned OFF when the beam is blocked.

• The power supply to the motor M is kept OFF until the beams are unblocked and the reset switch S2 is pressed.

Note: It cannot be used as a muting system when F3SP-B1P is used.

Highest achievable PL/

safety category

Model Stop category Reset

PLe/4 equivalent

Safety Light Curtain F3SJ-A@@@@P@@

Control Unit F3SP-B1P

Safety Relay G7SA

0 Manual

[PNP Output]

Safety

output 1

Safety

output 2

K1

K2

F3SP-B1P

* Auxiliary output 1 gives inverted signal of safety output (default setting).

Wiring for auto reset mode

T32

T31

Wiring when the external device

monitoring function will not be used

External device

monitoring

Included short bar

+24V

KM3

PLC

IN1 IN2 OUT

S1

S2

Reset

Auxiliary

output 1

External device

monitoring

Test

Interlock

selection

Unblocked

Blocked

External test switch (S1)

Reset switch (S2)

Safety output

K1,K2 N.O. contact

KM1,KM2 N.O. contact

K1,K2 N.C. contact

KM1,KM2 N.C. contact

PLC input 1 *

PLC input 2

PLC output

Reset

Test

Interlock

selection

- Using external device monitoring function

S1 : External test switch

S2 : Interlock/lockout reset switch

KM1, KM2 : Safety relay with force-guided

contact (G7SA) or magnetic contactor

KM3 : Solid state contactor (G3J)

M : 3-phase motor

PLC : Programmable controller

(Used for monitoring -- not related to safety

system)

T31 T32

14 24 34 42

A2 PE

A1 H1 L1 J1 H1 X1 P1 13 23 33 41

KM1

KM2

KM1

KM2

K1 K2

Receiver Emitter

F39-JD@B-L F39-JD@B-D

0 V

+24 VDC

Power

supply

M

KM2

KM1

S1

S2

X1H1J1L1H1

Loading...

Loading...