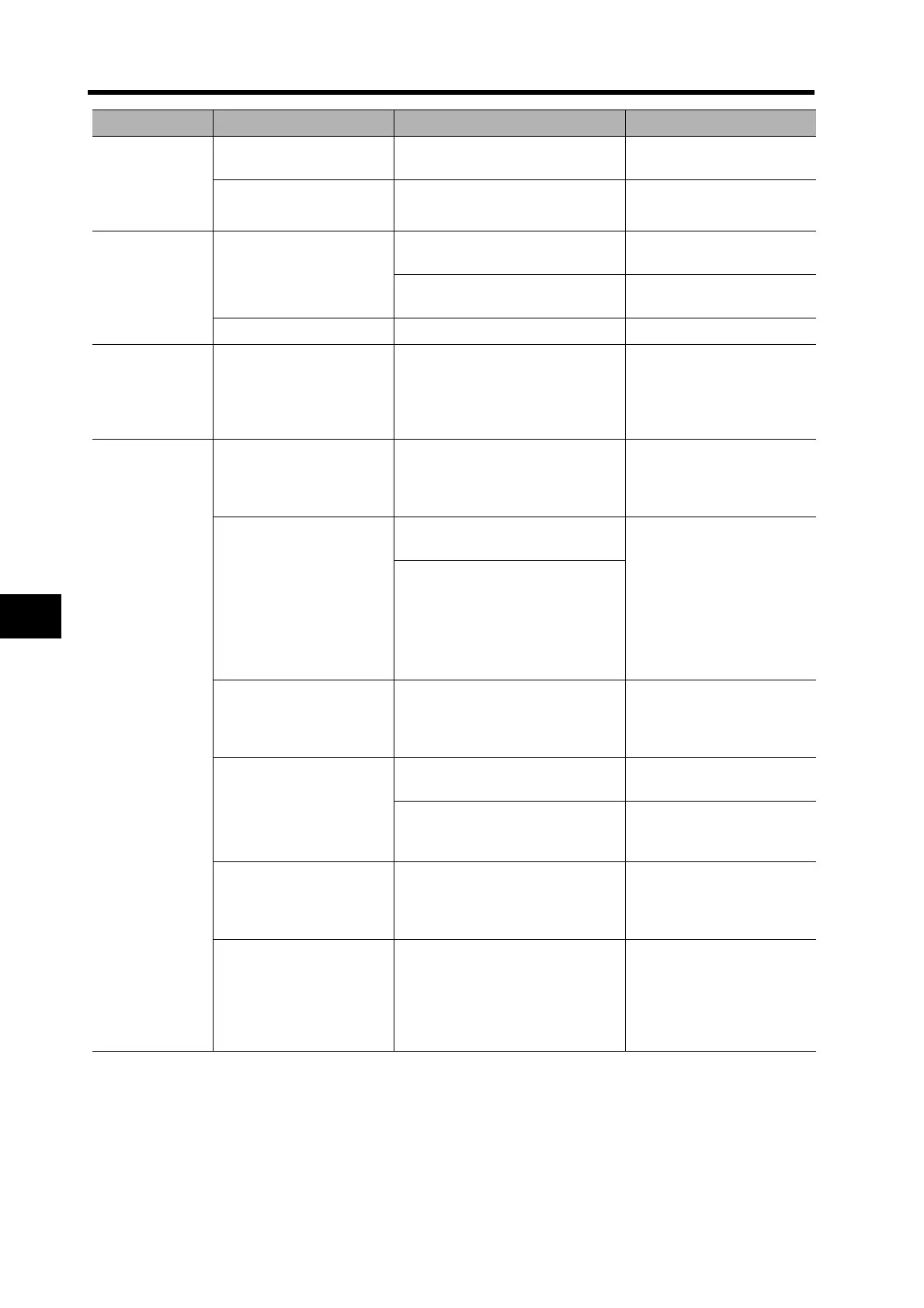

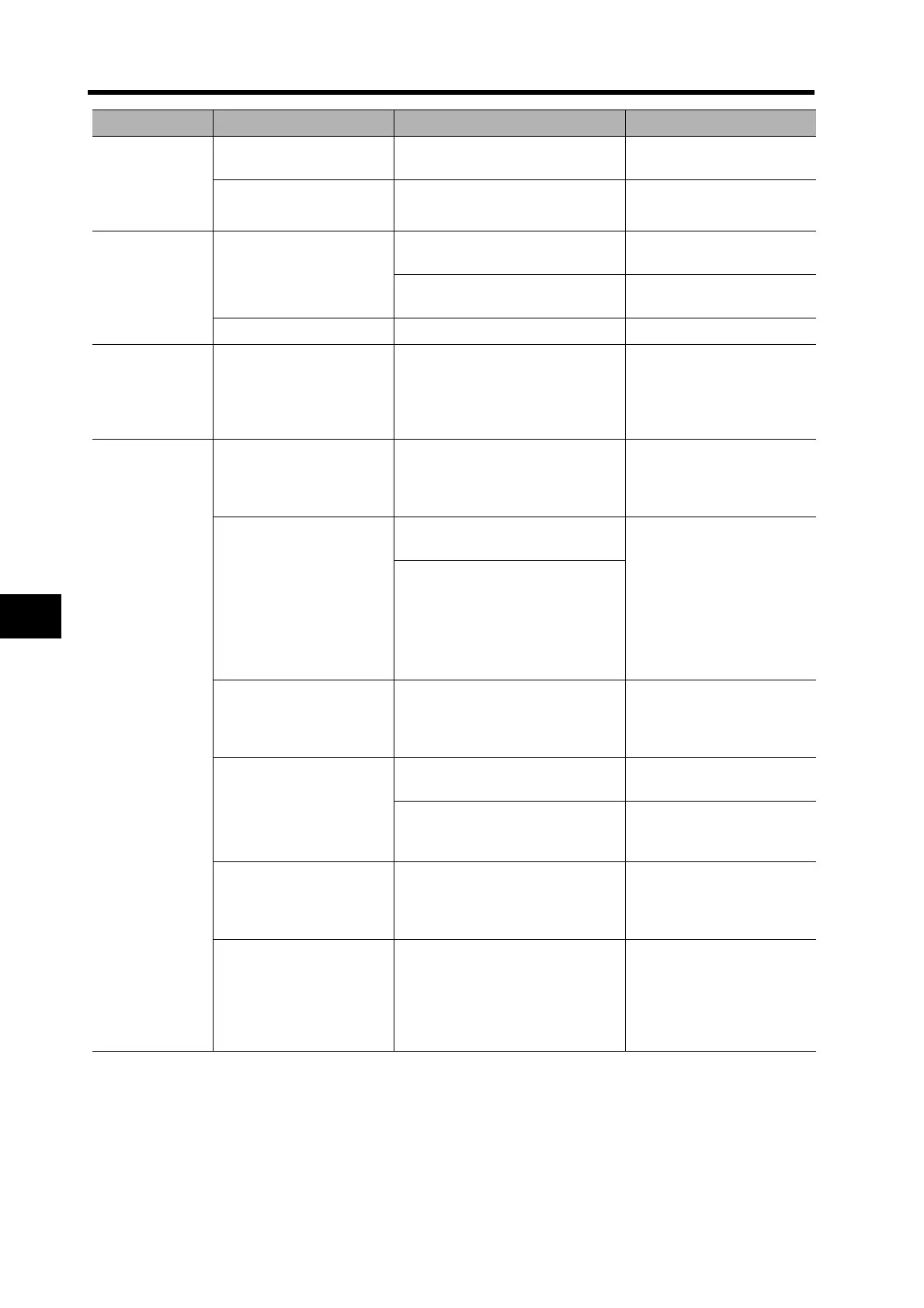

8-13

8-3 Troubleshooting

8

Troubleshooting

The Servomotor

operates mo-

mentarily, but it

does not operate

after that.

The Servomotor Power

Cable is wired incorrectly.

Check the wiring of the Servomotor

Power Cable’s phases U, V, and W.

Wire correctly.

The Encoder Cable is

wired incorrectly.

Check the Encoder Cable’s wiring. Wire correctly.

The Servomotor

rotates without a

command.

The command pulse input

is incorrect.

Check the command pulse type. Set the command pulse in-

put appropriately.

Check the command pulse’s volt-

age.

Connect a resistor that

matches the voltage.

The Servo Drive is faulty. --- Replace the Servo Drive.

The Servomotor

rotates in the

opposite

direction from

the command.

The CW input and CCW

input are connected

reversely.

Check the Controller’s command

pulse type and the Servo Drive’s

command pulse type.

Connect the CW pulse sig-

nal to the CW Input and the

CCW pulse signal to the

CCW Input.

Servomotor

rotation is

unstable.

The Servomotor Power

Cable or Encoder Cable is

wired incorrectly.

Check the wiring of the Servomotor

Power Cable’s phases U, V, and W

and check the Encoder Cable’s wir-

ing.

Wire correctly.

The coupling system

between the Servomotor

shaft and the mechanical

system has eccentricity

and declination, loose

screws, or the torque is

fluctuating due to

engagement between

pulleys or gears.

Check the mechanical system’s

coupling section.

Review and adjust the ma-

chine.

Try rotating the Servomotor without

a load. (Disconnect it from the me-

chanical system.)

The load’s moment of

inertia exceeds the Servo

Drive’s allowable value.

Try rotating the Servomotor without

a load. (Disconnect it from the me-

chanical system.)

• Reduce the load.

• Replace it with the Servo-

motor and Servo Drive with

higher capacity.

The pulse signal line’s

connections failure.

Check the pulse signal wiring at the

Controller and Servo Drive.

Wire correctly.

Check the Controller’s command

pulse type and the Servo Drive’s

command pulse type.

Set the Servo Drive’s pulse

type to match the Control-

ler’s command pulse type.

The gain doesn’t match. According to load (non-load is in-

cluded), adjust an inertia ratio and

a gain to a suitable value from fac-

tory setting.

• Use autotuning.

• Perform manual tuning.

The CN1 input signal is

chattering.

Check the RUN Command Input

(RUN), Deviation Counter Reset In-

put (ECRST), Zero Speed Desig-

nation Input (VZERO), Internally

set Speed Selection 1, 2 (VSEL1,

VSEL2).

Correct the wiring so that

there is no chattering.

Symptom Probable cause Items to check Countermeasures

Loading...

Loading...