Practical examples Section 5-2

345

SPEED AXIS(shear_axis)=cut_speed

MOVEABS(end_pos) AXIS(shear_axis)

MOVEABS(0) AXIS(shear_axis)

WAIT UNTIL NTYPE AXIS(shear_axis)=2

'Fast speed to return

WAIT LOADED AXIS(shear_axis)

SPEED AXIS(shear_axis)=return_speed

cut_counter=cut_counter+1inch

'Return back synchronized with the master in

'such a way that there is no wait time

line_back=cut_length-synch_dist-l_dec-l_acc

shear_cut=l_acc/2+synch_dist+l_dec/2)

MOVELINK(-shear_cut,line_back,l_acc/4,l_dec/

4,line_axis) AXIS(flying_axis)

GOTO loop

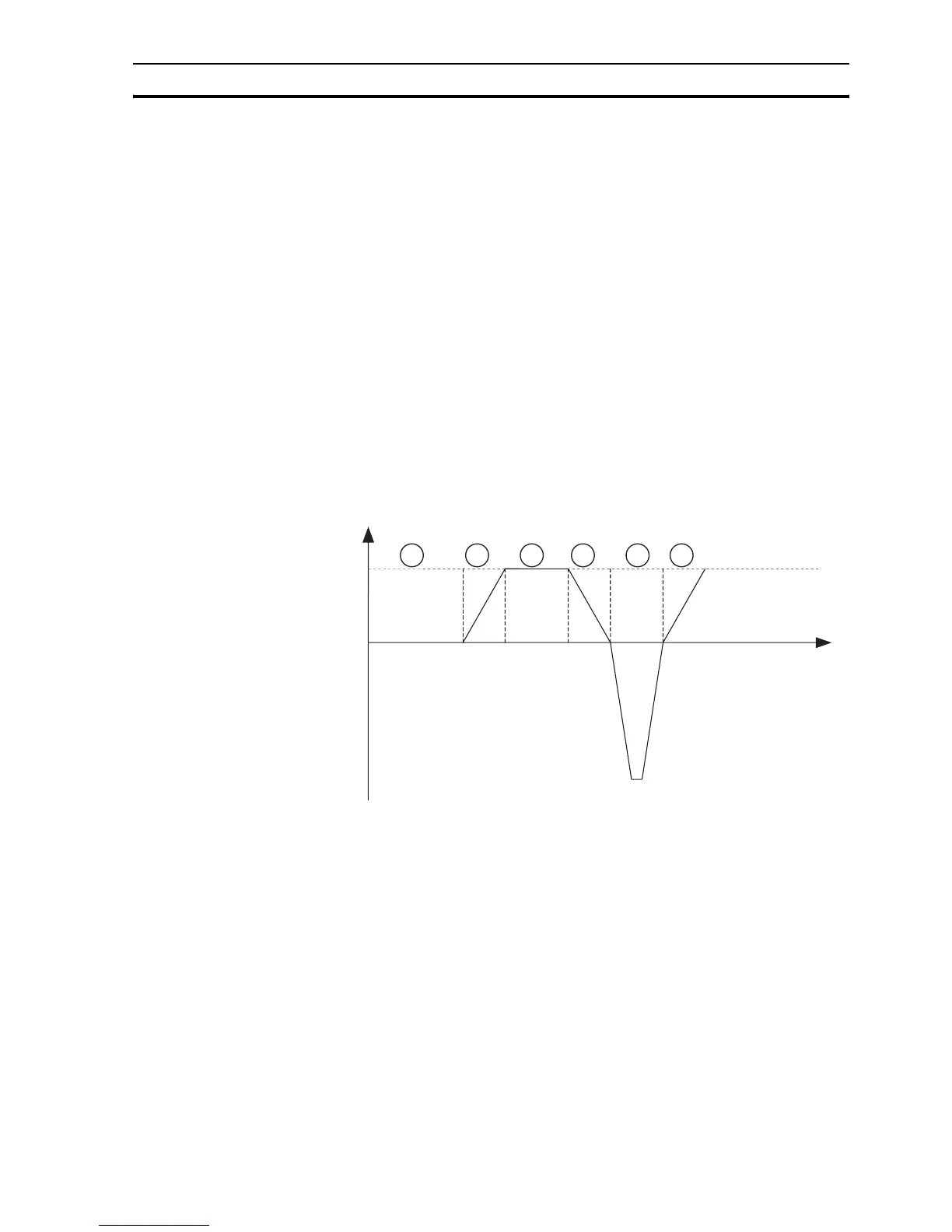

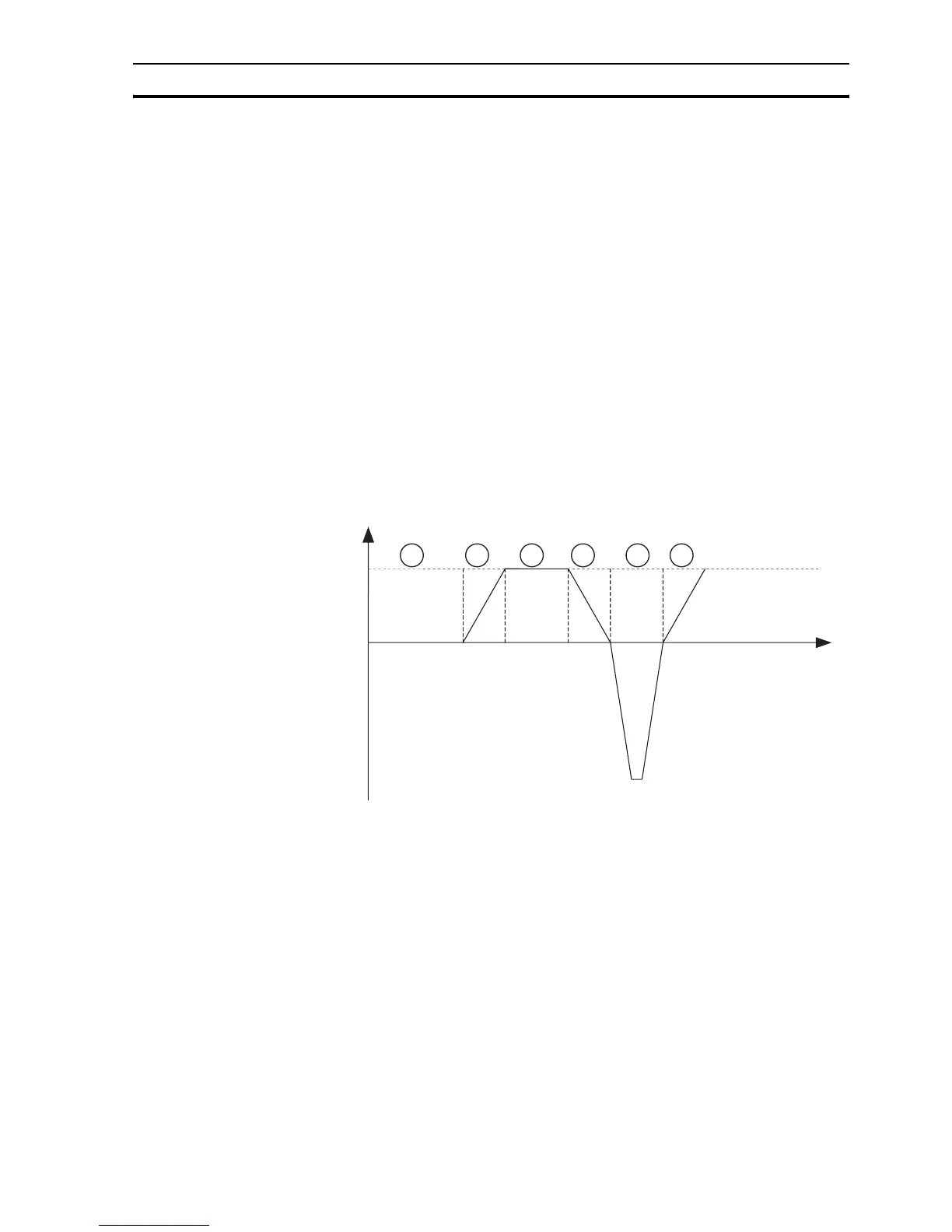

The speed-time graph shows the steps of the above example. The steps are:

1 The initial cycle: the slave waits for the right length in the product to cut

(cut_length – distance_to_accelerate / 2). It is necessary to divide

distance_to_accelerate when we use the MOVELINK command, because

when we synchronize, the master moves twice the distance of the slave.

2 The slave accelerates to synchronize with the master. When the

acceleration finishes, the relative distance between the edge of the product

and the shear is cut_length.

3 This is the synchronization part: the relative distance between the edge of

the product and the shear remains the same. The cut in the material is

made. This gives a new material edge.

4 The deceleration part: the material continues, and the shear stops.

5 Move back at high speed: the distances are calculated such that when the

slave reaches it original position, the edge of the product is in the correct

position to start a new cut.A

SPEED

t

1

2

234 5

Loading...

Loading...