18

These are the values for materials passed through or placed at the level of the workbed. For

thicker materials, find their height relative to the bed’s usual level, roughly 2¾ in. (70 mm) above

the bottom of the laser’s support legs.

Step 7 Adjust your software’s parameters to suit your project. When working with new materials,

remember that you should always start on the low end of likely settings. If the effect is not yet

strong enough, you can always rerun the design loop several times or rerun it with more powerful

settings until you create the effect that you want.

It is NOT recommended to use the laser at full power. The recommended maximum power setting

is 70%, as prolonged use above that amount will shorten your laser’s service life. The threshold for

the lowest setting is around 10% and the laser may not fire at all when set lower than this.

To the laser’s engraving or cutting effect without increasing its raw power, increase the amount

of energy per unit area by decreasing the speed parameter or increasing the number of loops.

Working too intensely, however, increases the risk of fire and reduces image quality, especially

with coated materials.

Resolution should usually be set to 500 dots per inch. Reducing your image resolution can be helpful

in some cases, reducing flaming and increasing the energy of the pulse in a way that improves the

quality of the resultant image in some materials such as some plastics.

Step 8 Activate your laser tube by inserting and turning your laser key.

Step 9 Begin engraving your design. Watch for possible issues like sparks or fires using the camera view.

Do not stare continuously at the active laser even through the cover’s protective window. Be

prepared to quickly extinguish a fire if necessary. If any dust or fumes begin to build up within the

main bay, increase the power of the duct fan or pause work periodically to allow it to clear the air.

Step 10 Once the laser has stopped, examine the quality of your first run. Adjust the parameters in your

software as necessary and begin your real work in a different location or on a different piece of

material.

If your engraver stops during repetitive engraving and cutting, the cooling system may have

reached 122°F (50°C) and automatically paused work. Resume work only after system has had

time to adequately cool. If possible, use lower power settings while reducing speed or increasing

the number of times your design is processed.

Step 11 When you have finished your project, close your engraving software and remove the laser key.

Allow the cooling and ventilation systems to continue to run until the air in the main bay is clear

and the tube has safely cooled. Turn off the engraver using its main power switch and then turn

off the external fan. For best results, fully unplug your engraver or turn off its intermediary surge

protector.

Step 12 Open the cover and remove any dust or debris buildup from the workbed and the various surfaces

within the bay. Remove the debris tray, empty and clean it, and replace it.

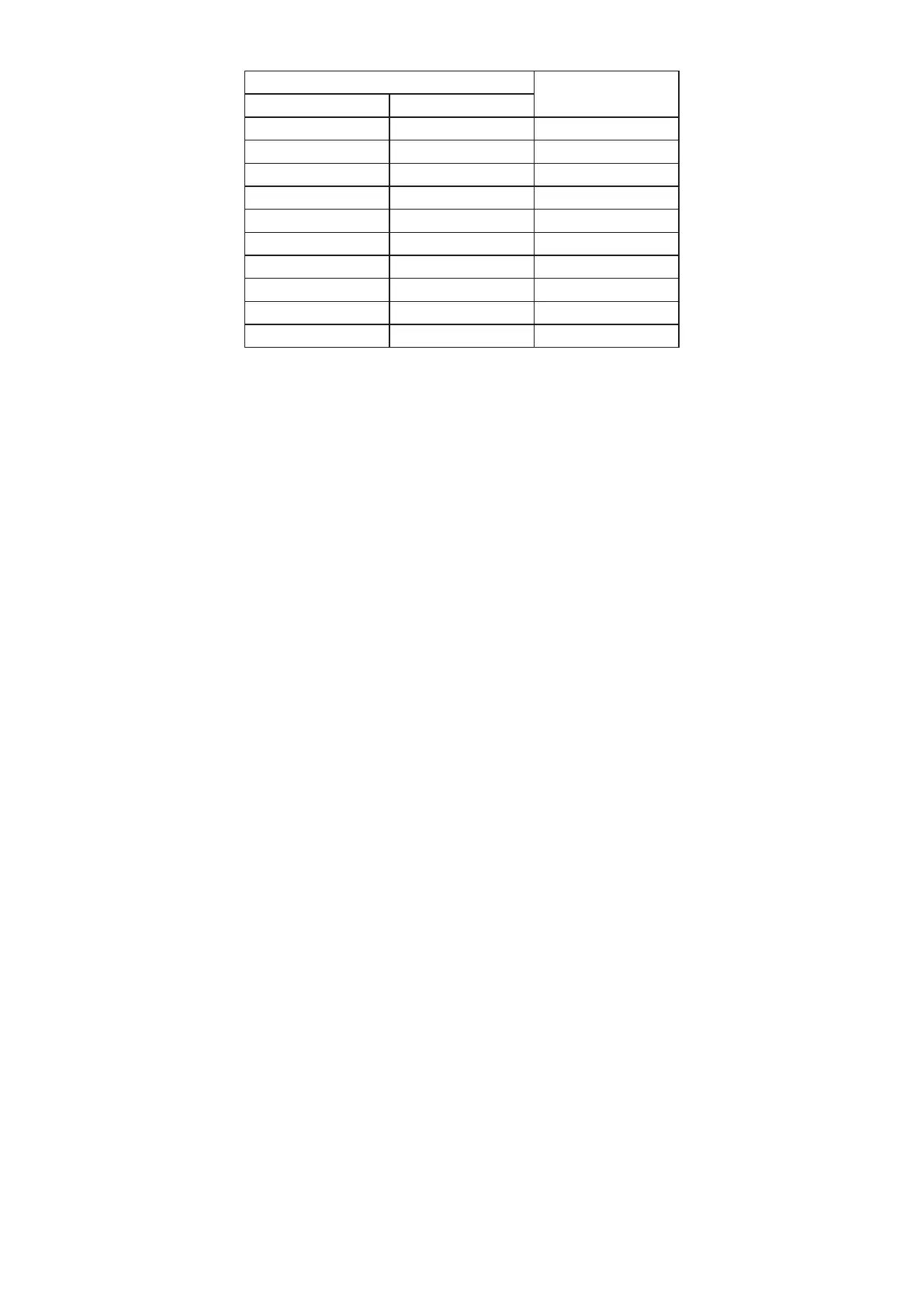

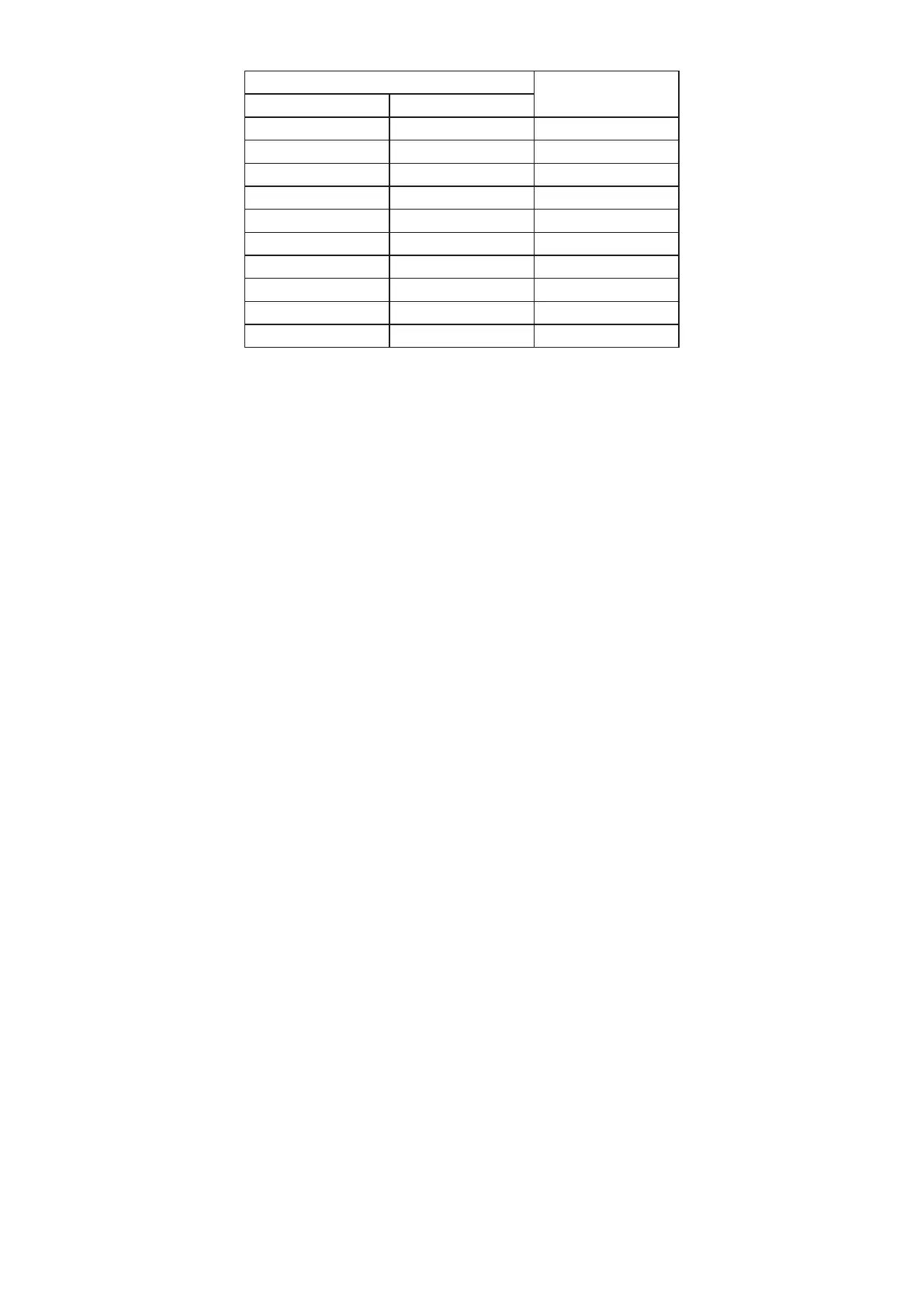

Material Thickness Offset

Value

Inches mm

0 0.000 17.000

0.1 2.540 14.460

1/8 3.175 13.825

0.2 5.080 11.920

1/4 6.350 10.650

0.3 7.620 9.380

3/8 9.525 7.475

0.4 10.160 6.840

1/2 12.700 4.300

0.59 15.000 2.000

Loading...

Loading...