Valve Seat Removal

Procedure

1 . Remove carbon and combustion deposits

from the valve seat.

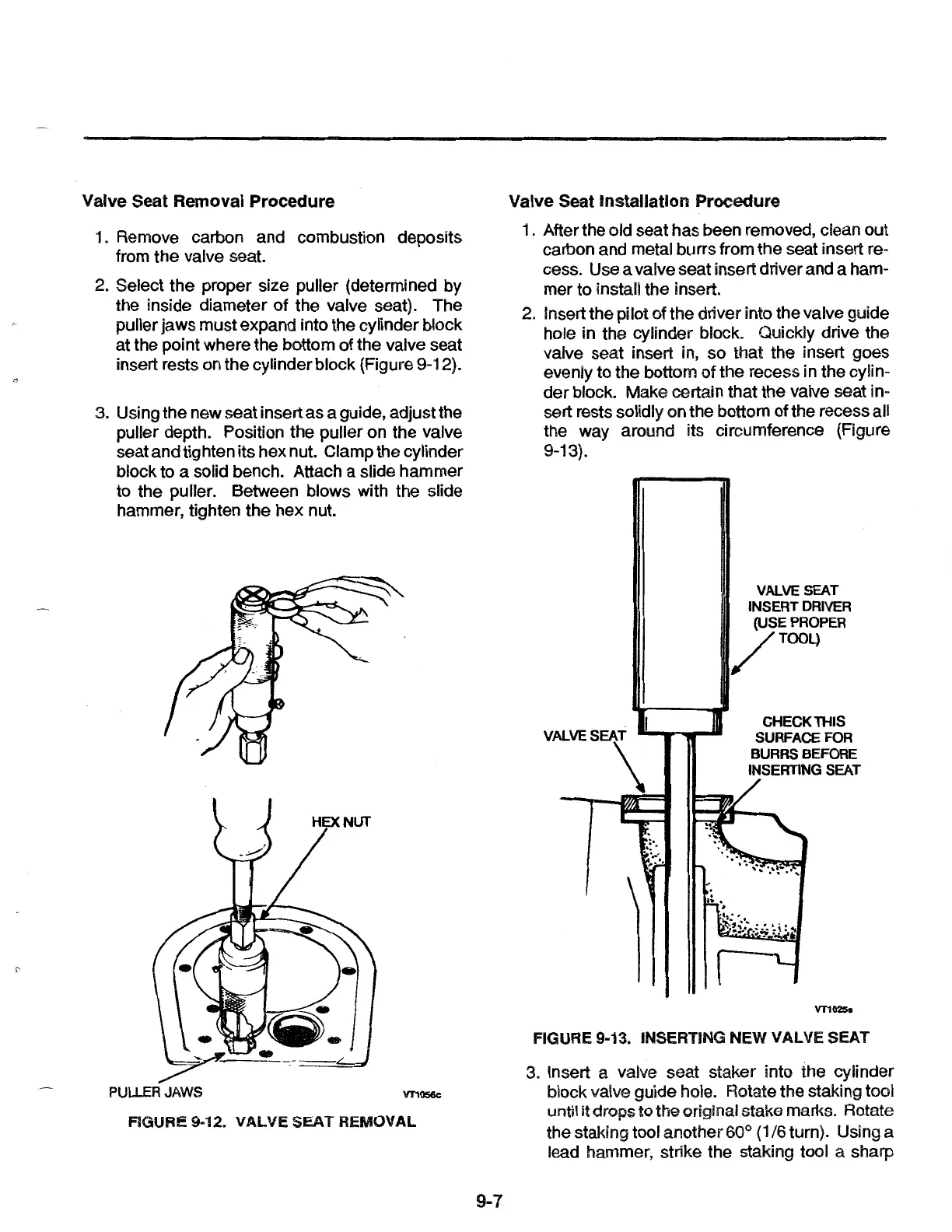

2. Select the proper size puller (determined by

the inside diameter of the valve seat). The

puller jaws must expand into the cylinder block

at the point where the bottom of the valve seat

insert rests on the cylinder block (Figure 9-12).

3. Using the new seat insert as a guide, adjust the

puller depth. Position the puller on the valve

seat and tighten its hex nut. Clamp the cylinder

block to a solid bench. Attach a slide hammer

to the puller. Between blows with the slide

hammer, tighten the hex nut.

PULLER JAWS

VT1056c

FIGURE

9-12.

VALVE

SEAT

REMOVAL

9-7

Valve Seat

Installation

Procedure

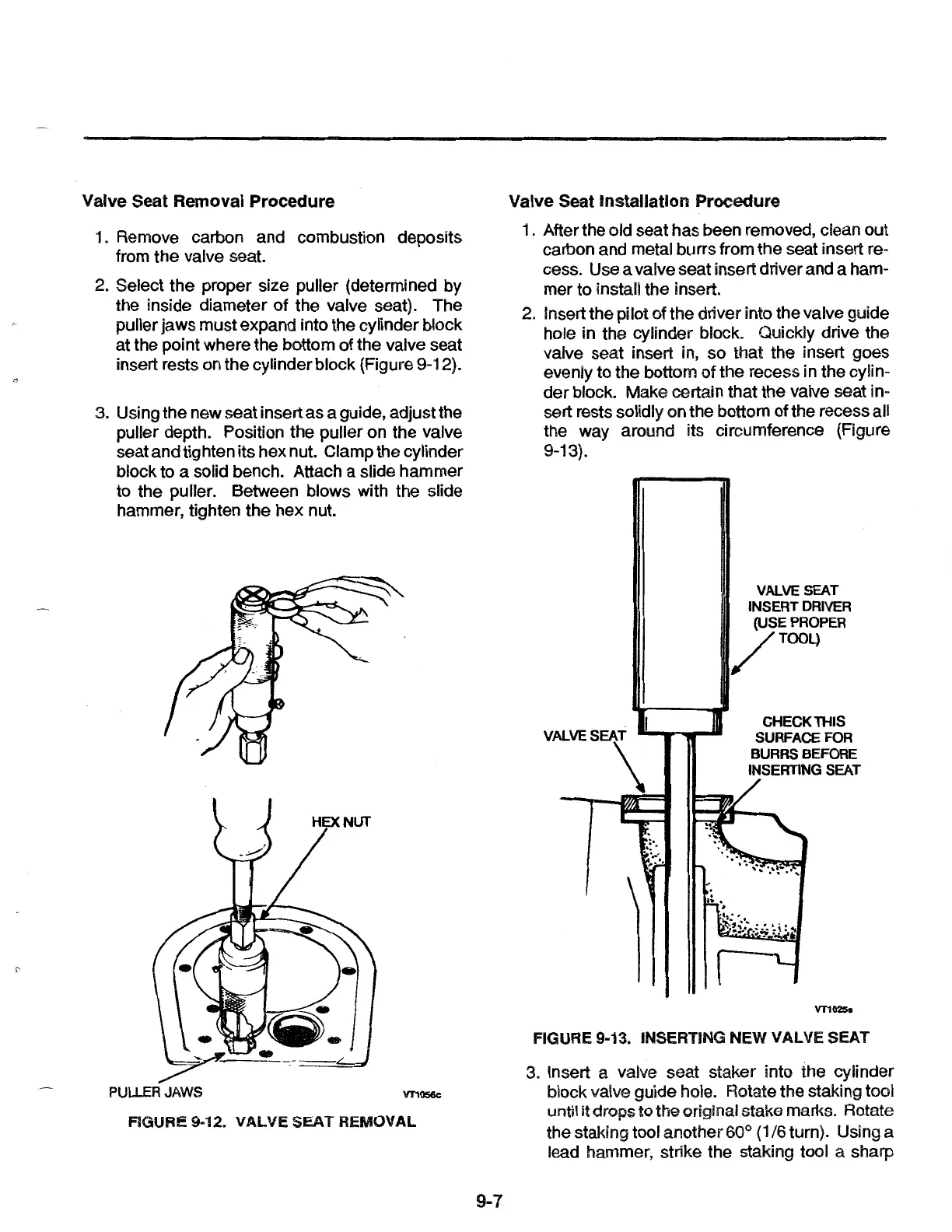

1 . After the old seat has been removed, clean out

carbon and metal burrs from the seat insert re-

cess. Use a valve seat insert driver and a ham-

mer to install the insert.

2. Insert the pilot of the driver into the valve guide

hole in the cylinder block. Quickly drive the

valve seat insert in, so that the insert goes

evenly to the bottom

of

the recess in the cylin-

der block. Make certain that the valve seat in-

sert rests solidly on the bottom of the recess all

the way around its circumference (Figure

9-13).

VALVE SEAT

INSERT DRIVER

(USE PROPER

/TOOL}

CHECK

THIS

SURFACE FOR

BURRS BEFORE

INSERTING SEAT

VT1025s

FIGURE 9-13. INSERTING NEW VALVE SEAT

3. Insert a valve seat staker into the cylinder

block valve guide hole. Rotate the staking tool

until

it

drops

to

the

original

stake

marks. Rotate

the staking tool another 60° (1/6 turn). Using a

lead hammer, strike the staking tool a sharp

Loading...

Loading...