2. Loosen the throttle stop screw locknut and

back the screw out away from the tang on the

throttle lever, while gently rotating the throttle

lever counterclockwise as far as if will go.

3. While gently holding the throttle lever counter-

clockwise as far as it will go, turn the stop screw

in until it just touches the tang. Then turn the

screw an additional 118-1/4 turn (clockwise)

and set and seal the locknut.

If the throttle stop screw adjustment is okay, recon-

nect the governor rod as follows:

1.

Insert the rod in the spring such that the shorter

hook wire is on the throttle side.

2. Hook the rod and spring into the grommet in the

throttle lever. (The spring should pull on one

side and the rod push on the other side

of

the

grommet when fully assembled.)

3. Pull the governor rod towards the plastic clip on

the end of the actuator lever as far as the

throttle stop screw permits. Leave the actuator

lever in its fully counterclockwise (rest) posi-

tion. Snap the dogleg on the end

of

the rod into

the slot in the clip that most closely lines up with

it. Use both hands so as not to bend the actua-

tor lever.

4.

Hook the spring into the slot in the end of the

actuator lever. When assembled, the spring

hook wires should not wrap around the gover-

nor rod.

5.

Move the actuator back and forth through its full

movement

to

make certain there is no sticking

or binding.

6. After installing the top panel, hook the spark

plug cable with the clip inside the panel to keep

it from interfering with the governor rod.

Idle Fuel Mixture

Adjustment:

These instructions

do

not apply

to

Spec F and later gensets.

1.

If the carburetor has been overhauled, gently

turn the idle and main fuel mixture screws in

by

hand until they seat.

For

Gasoline Gensets: Turn the idle mixture

screw out 1 turn and the main fuel mixture

screw out 1-3/8 turns so that the engine will

start and run.

6-15

For

LPG Gensets: Turn the idle mixture screw

out 1-1/4 turns and the main fuel mixture screw

out 2-1/2 turns

so

that the engine will start and

run.

lA CAUTION!

Forcing

a

mixture

adjusting

screw

in

tight

will

score

the needle

and

seat.

Turn

it

lightly

by

hand

only.

2. Start the genset and let it warm up for ten min-

utes under 1/2 to 3/4 rated load. (On vapor

withdrawal type LPG gensets it might be nec-

essary first to adjust the demand regulator and

supply pressure to get the genset to start. See

LPG

System-Vapor

Withdrawal.)

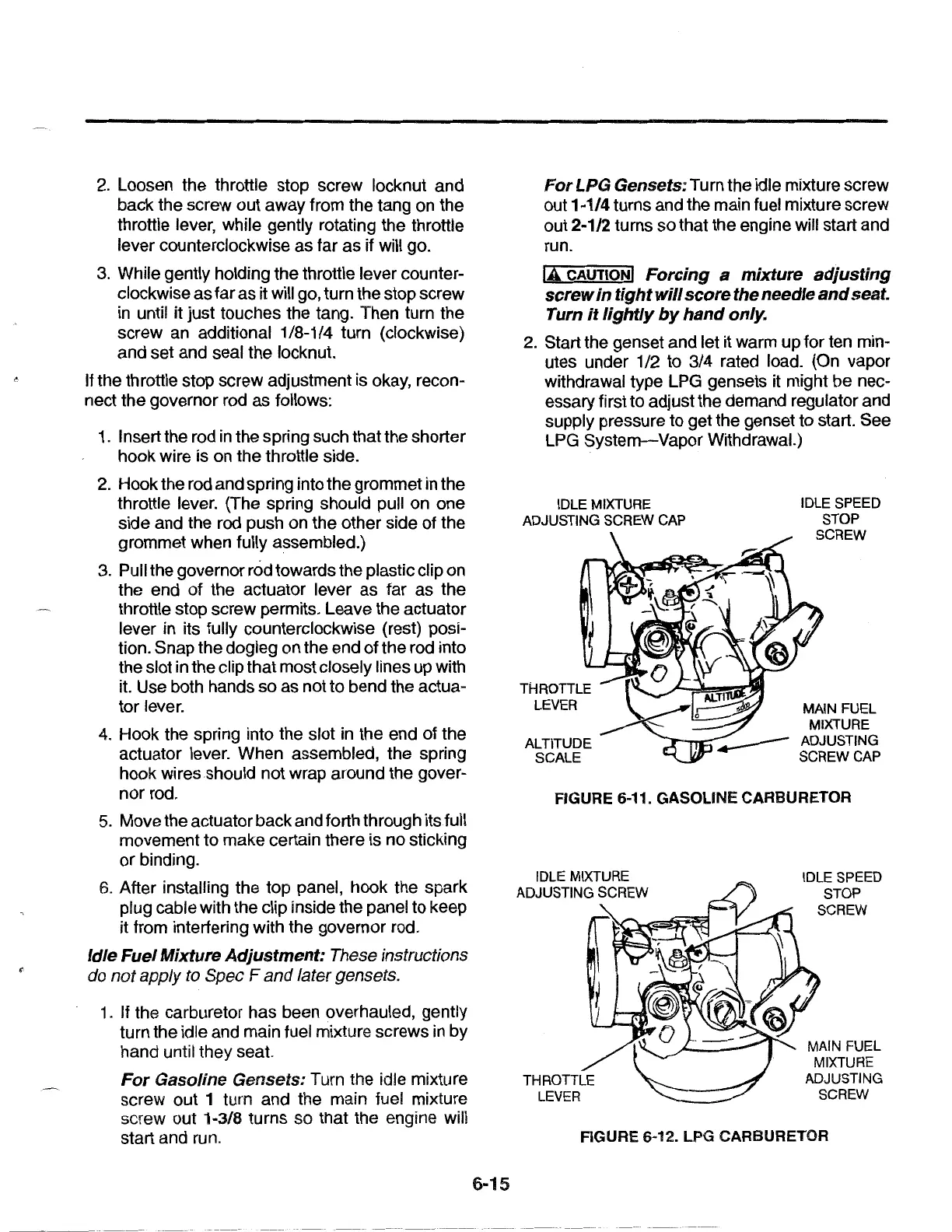

IDLE MIXTURE

ADJUSTING SCREW CAP

ALTITUDE

SCALE

IDLE SPEED

STOP

SCREW

MAIN FUEL

MIXTURE

~ADJUSTING

SCREW CAP

FIGURE 6-11. GASOLINE CARBURETOR

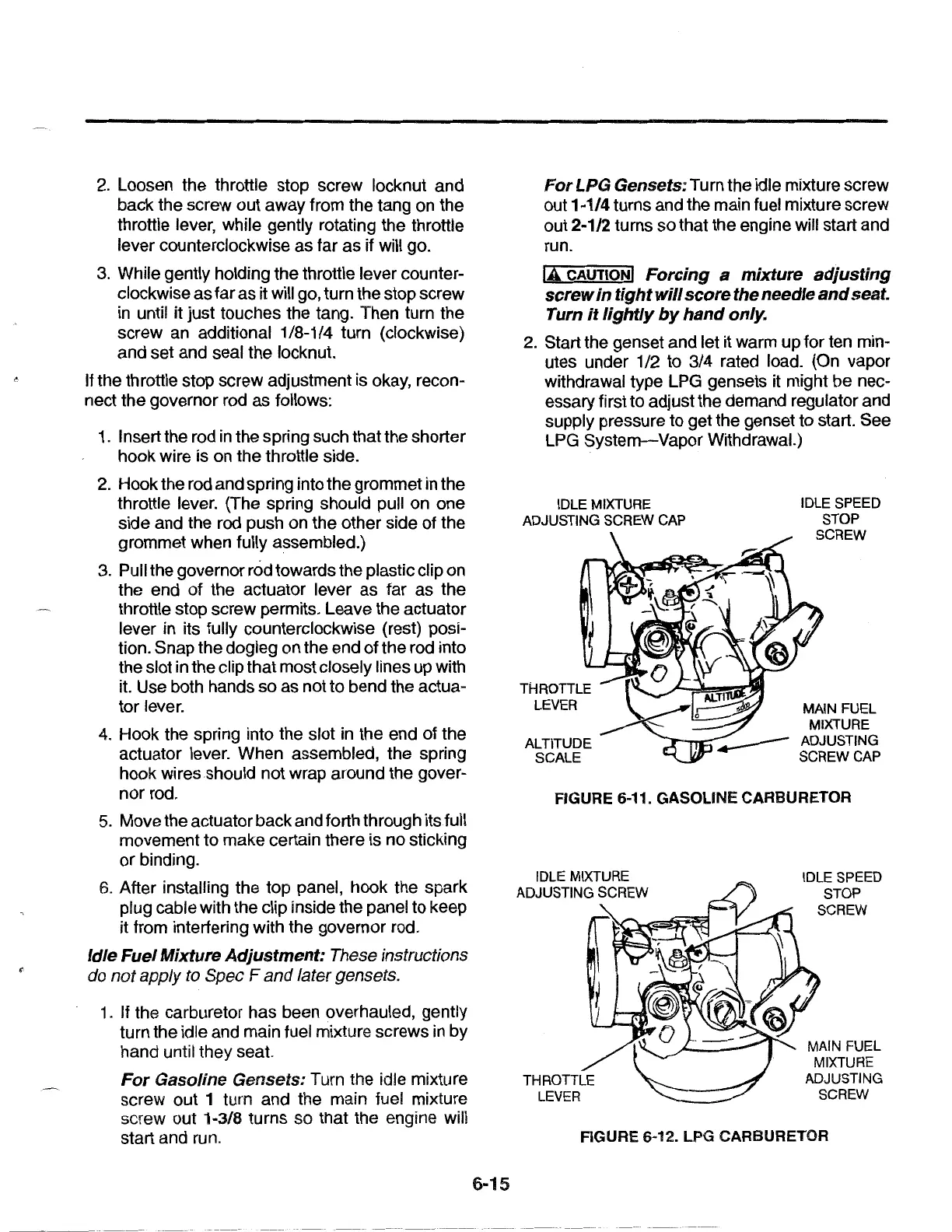

IDLE SPEED

STOP

SCREW

MAIN FUEL

MIXTURE

ADJUSTING

SCREW

FIGURE

6-12.LPG

CARBURETOR

Loading...

Loading...