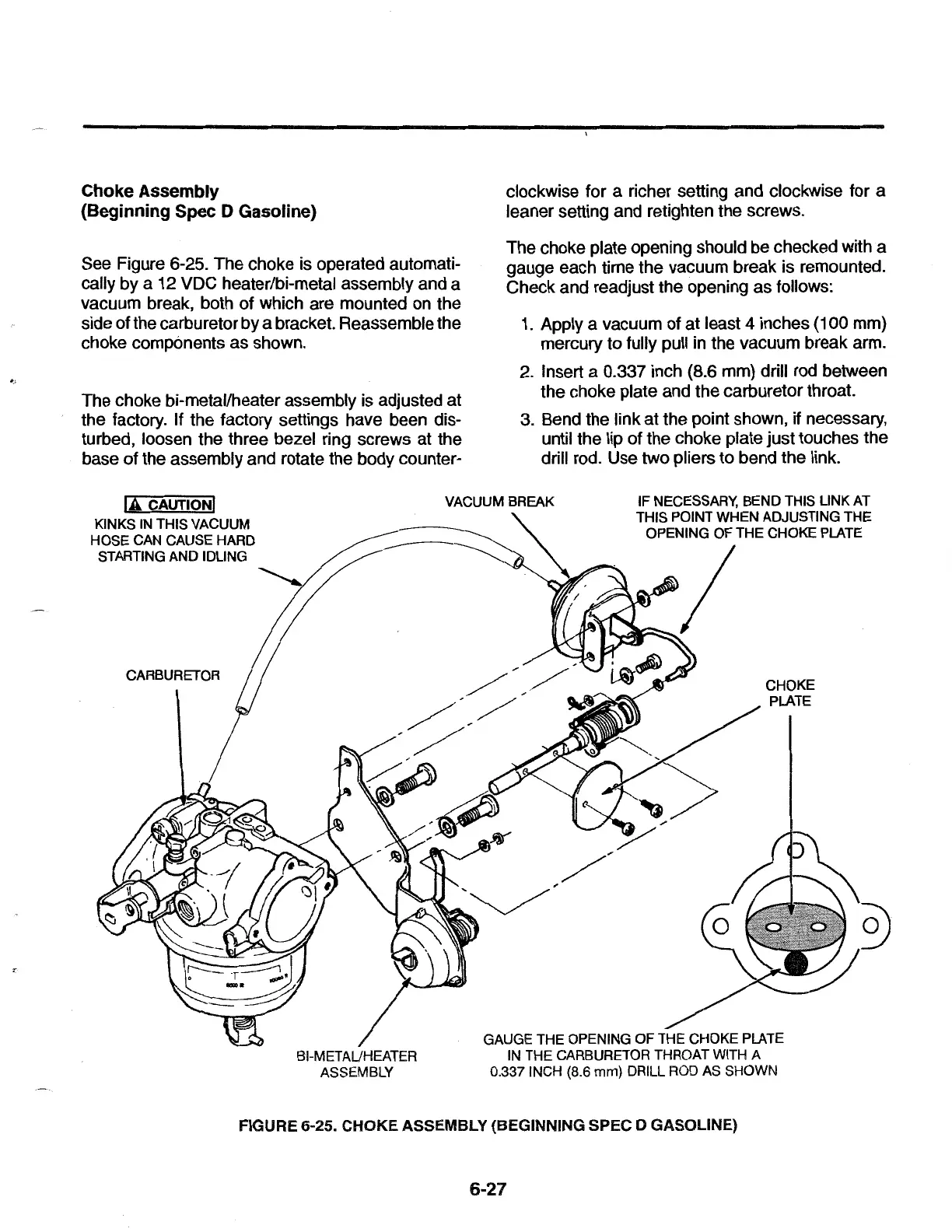

Choke Assembly

(Beginning Spec D Gasoline)

See Figure 6-25. The choke is operated automati-

cally by a 12 VDC heater/bi-metal assembly and a

vacuum break, both

of

which are mounted on the

side of the carburetor by a bracket. Reassemble the

choke components as shown.

The choke bi-metal/heater assembly is adjusted at

the factory. If the factory settings have been dis-

turbed, loosen the three bezel ring screws at the

base of the assembly and rotate the body counter-

JA

CAUTIONJ

KINKS IN THIS VACUUM

HOSE

CAN CAUSE HARD

STARTING

AND

IDLING

CARBURETOR

BI-METAL/HEATER

ASSEMBLY

clockwise for a richer setting and clockwise for a

leaner setting and retighten the screws.

The choke plate opening should be checked with a

gauge each time the vacuum break is remounted.

Check and readjust the opening

as

follows:

1.

Apply a vacuum of

at

least 4 inches

(1

00 mm)

mercury to fully pull in the vacuum break arm.

2.

Insert a 0.337 inch (8.6 mm) drill rod between

the choke plate and the carburetor throat.

3.

Bend the link at the point shown, if necessary,

until the lip of the choke plate just touches the

drill rod. Use two pliers to bend the link.

IF NECESSARY, BEND THIS LINK AT

THIS POINT

WHEN

ADJUSTING

THE

OPENING

OF

THE CHOKE PLATE

~/

CHOKE

PLATE

GAUGE THE OPENING

OF

THE CHOKE PLATE

IN THE CARBURETOR THROAT WITH A

0.337 INCH {8.6

mm) DRILL ROD AS SHOWN

FIGURE 6-25. CHOKE ASSEMBLY (BEGINNING SPEC D GASOLINE)

6-27

Loading...

Loading...