Repair:

Repair kits are available that provide replacements

for those parts of the pump most subject to wear. If

the operator chooses to repair the pump rather than

install a new one, the use of all parts included in the

repair kit is recommended. Proceed as follows:

1.

After the pump is removed from the engine,

scribealineon theflangesoftheupperand lower

pump bodies to assure correct positioning when

reassembling.

2.

Remove the securing screws and separate the

upper and lower pump bodies.

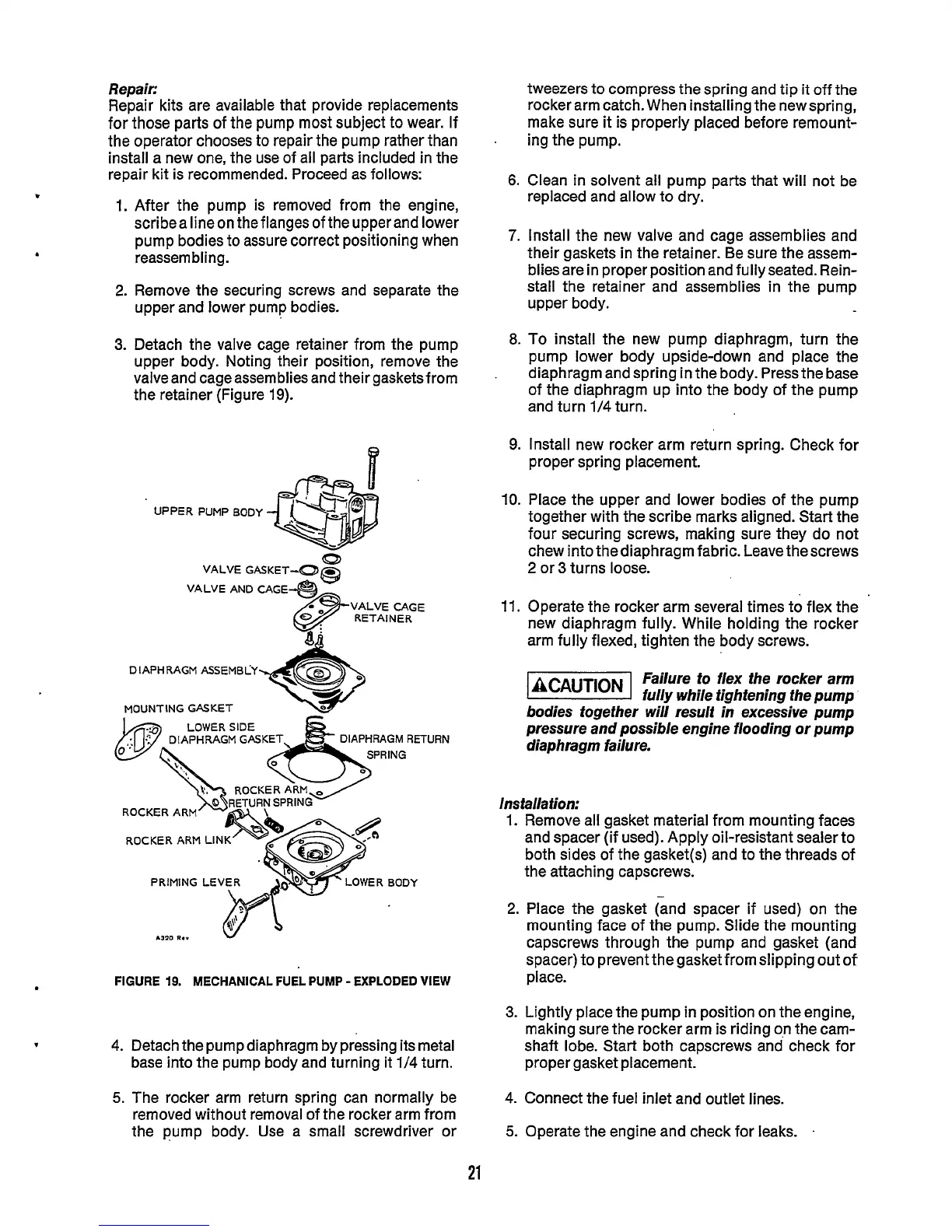

3.

Detach the valve cage retainer from the pump

upper body. Noting their position, remove the

valve and cageassemblies and their gasket sfrom

the retainer (Figure

19).

UPPER PUMP BODY

8R

LOWER SIDE

DIAPHRAGM CASK

IAPHRAGM

RETURN

ROCKER

AR

ROCKER

ARM

LIN

PRIMING

LEV

FIGURE

19.

MECHANICAL FUEL PUMP

-

EXPLODED VIEW

4.

5.

tweezers to compress the spring and tip

it

off the

rocker arm catch. When installing the newspring,

make sure it is properly placed before remount-

.

ing the pump.

6.

Clean

in

solvent all pump parts that will not be

replaced and allow to dry.

7.

Install the new valve and cage assemblies and

their gaskets in the retainer.

Be

sure the assem-

blies are in proper position and fully seated. Rein-

stall the retainer and assemblies in the pump

upper body.

8.

To install the new pump diaphragm, turn the

pump lower body upside-down and place the

diaphragm and spring in the body. Press the base

of the diaphragm up into the body of the pump

and turn

1/4

turn.

.

9.

Install new rocker arm return spring. Check for

proper spring placement.

10.

Place the upper and lower bodies

of

the pump

together with the scribe marks aligned. Start the

four securing screws, making sure they do not

chew into thediaphragm fabric. Leave thescrews

2

or

3

turns loose.

11.

Operate the rocker arm several times

to

flex the

new diaphragm fully. While holding the rocker

arm fully flexed, tighten the body screws.

-1

Failure

to

flex fhe rocker arm

fully while tighfening fhe pump

bodies together will result in excessive pump

pressure and possible engine flooding or pump

diaphmgm failure.

Installation:

1.

Remove all gasket material from mounting faces

and spacer (if used). Apply oil-resistant sealer to

both sides of the gasket(s) and

to

the threads

of

the attaching capscrews.

2.

Place the gasket (and spacer if used) on the

mounting face of the pump. Slide the mounting

capscrews through the pump and gasket (and

spacer) to prevent thegasketfromslipping out

of

place.

3.

Lightly place the pump

in

position on the engine,

making sure the rocker arm is riding o,n the cam-

shaft lobe. Start both capscrews and check for

proper gasket placement.

Detach the pump diaphragm by pressing its metal

base into the pump body and turning it

1/4

turn.

The rocker arm return spring can normally be

removed without removal of the rocker arm from

the pump body. Use a small screwdriver or

4.

Connect the fuel inlet and outlet lines.

5.

Operate the engine and check for leaks.

.

21

Loading...

Loading...