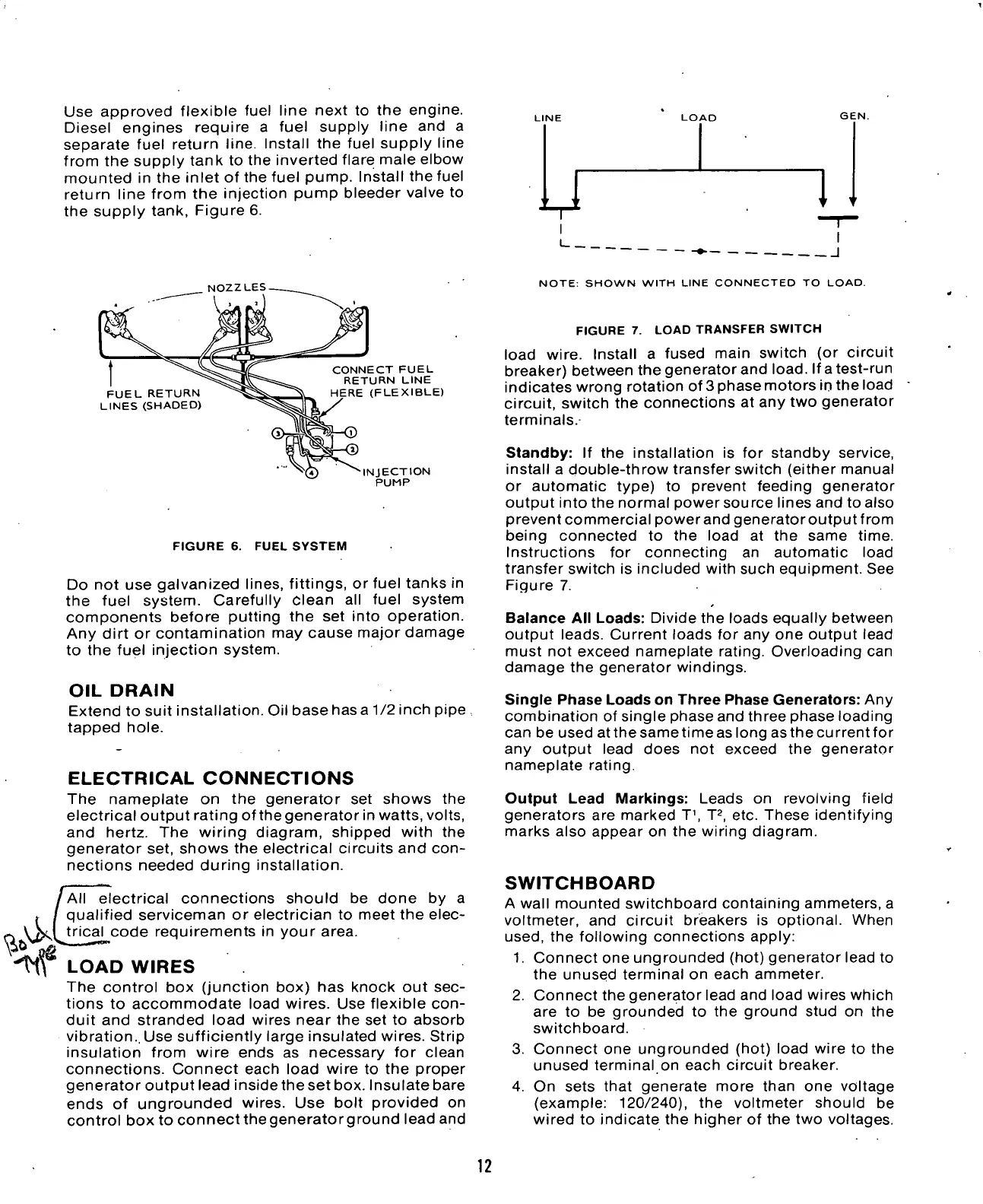

Use approved flexible fuel line next to the engine.

Diesel engines require a fuel supply line and a

separate fuel return line. Install the fuel supply line

from the supply tank to the inverted flare male elbow

mounted in the inlet of the fuel pump. Install the fuel

return line from the injection pump bleeder valve to

the supply tank, Figure 6.

LOAD

SEN.

NOZZLES-

FUEL RETURN

LINES (SHADED)

CONNECT FUEL

RETURN LINE

HERE (FLEXIBLE)

INJECTION

PUMP

FIGURE 6. FUEL SYSTEM

Do not use galvanized lines, fittings, or fuel tanks in

the fuel system. Carefully clean all fuel system

components before putting the set into operation.

Any dirt or contamination may cause major damage

to the fuel injection system.

OIL

DRAIN

Extend to suit installation. Oil base has a 1/2 inch pipe

tapped hole.

ELECTRICAL

CONNECTIONS

The nameplate on the generator set shows the

electrical output rating of the generator in watts, volts,

and hertz. The wiring diagram, shipped with the

generator set, shows the electrical circuits and

con-

nections needed during installation.

All electrical connections should be done by a

qualified serviceman or electrician to meet the elec-

trical code requirements in your area.

LOAD

WIRES

The control box (junction box) has knock out sec-

tions to accommodate load wires. Use flexible

con-

duit and stranded load wires near the set to absorb

vibration..

Use sufficiently large insulated wires. Strip

insulation from wire ends as necessary for clean

connections. Connect each load wire to the proper

generator output lead inside the set box. Insulate bare

ends of ungrounded wires. Use bolt provided on

control box to connect the generatorground lead and

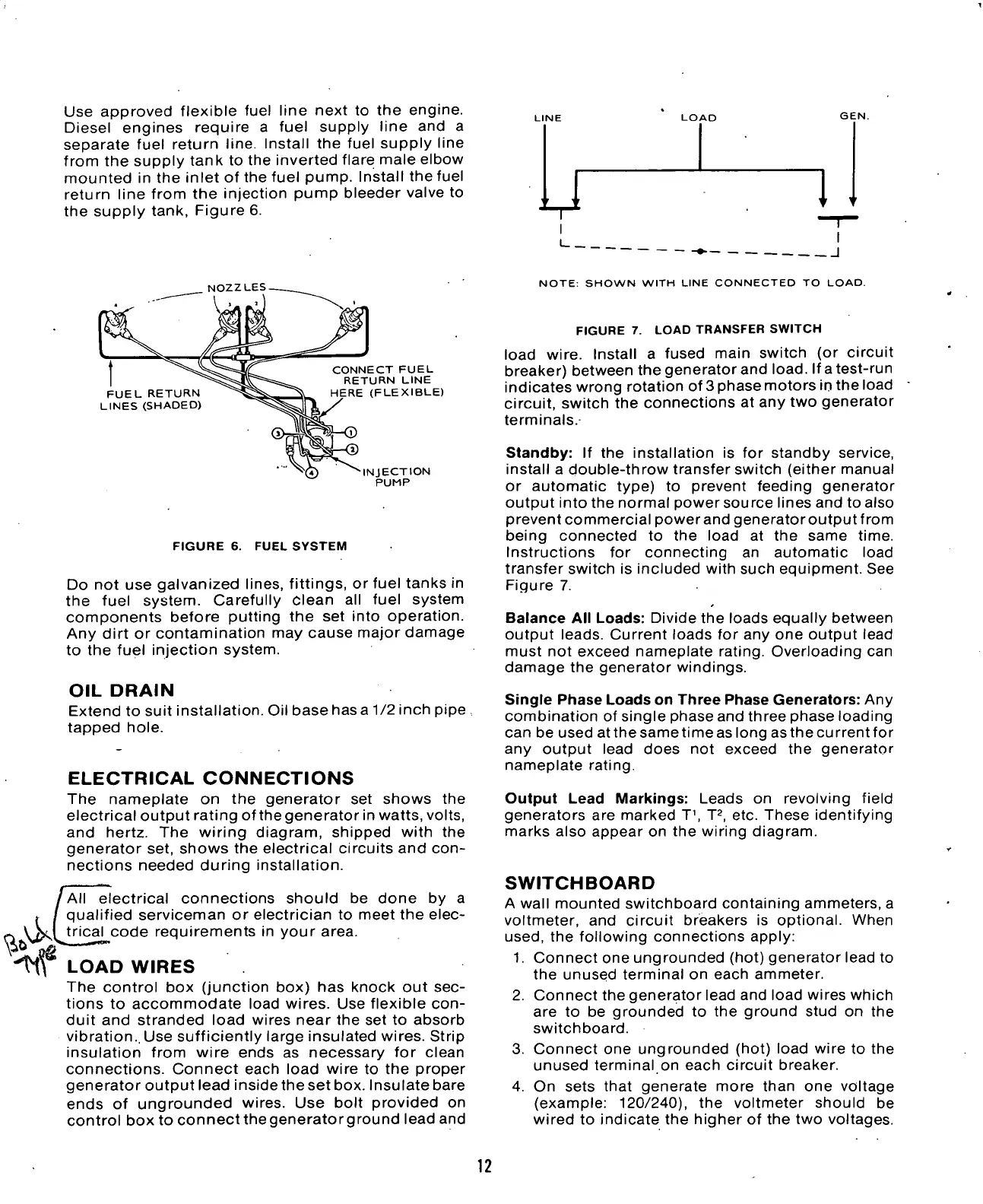

NOTE:

SHOWN WITH LINE CONNECTED TO LOAD.

FIGURE 7. LOAD TRANSFER SWITCH

load wire. Install a fused main switch (or circuit

breaker) between the generator and

load.

If a test-run

indicates wrong rotation of 3 phase motors in the load

circuit, switch the connections at any two generator

terminals.

Standby: If the installation is for standby service,

install a double-throw transfer switch (either manual

or automatic type) to prevent feeding generator

output into the normal power source lines and to also

prevent commercial power and generator output from

being connected to the load at the same time.

Instructions for connecting an automatic load

transfer switch is included with such equipment. See

Figure 7.

Balance All Loads: Divide the loads equally between

output leads. Current loads for any one output lead

must not exceed nameplate rating. Overloading can

damage the generator windings.

Single Phase Loads on Three Phase Generators: Any

combination of single phase and three phase loading

can be used at the same time as long as the current for

any output lead does not exceed the generator

nameplate rating.

Output Lead Markings: Leads on revolving field

generators are marked T

1

, T

2

, etc. These identifying

marks also appear on the wiring diagram.

SWITCHBOARD

A wall mounted switchboard containing ammeters, a

voltmeter, and circuit breakers is optional. When

used,

the following connections apply:

1.

Connect one ungrounded (hot) generator lead to

the unused terminal on each ammeter.

2.

Connect the generator lead and load wires which

are to be grounded to the ground stud on the

switchboard.

3. Connect one ungrounded (hot) load wire to the

unused terminal on each circuit breaker.

4.

On sets that generate more than one voltage

(example: 120/240), the voltmeter should be

wired to indicate the higher of the two voltages.

12

Loading...

Loading...