GENER

Follow a/etefm

vicing,

b;

ICE

AND MAINTENANCE

schedwfe of inspection and ser-

fig hours (Table 1). Keep an

accurate\ logbook Qf^ maintenance, servicing, and

operatingMmie Use the running time meter (optional

equipment)TEr1<eep a record of operation and ser-

vicing.

Regular service periods are recommended for

normal service and operating conditions. For

con-

tinuous duty, extreme temperature, etc., service more

frequently. For infrequent use, lightduty, etc., service

periods can be lengthened accordingly. Refer to

Figure 17 for engine maintenance information.

WARNING

Before commencing any maintenance work

on the engine, generator, control panel,

transfer switch or associated wiring, disconnect

automatic

batteries. Failure to do so could result in damage to the unit or

serious personal injury in the event of inadvertent starting.

Operator should periodically make a complete visual

inspection with set running at rated

load.

Some of the

things to check for are as follows:

1.

Check all fuel and oil lines for possible leakage.

2.

Inspect exhaust lines and mufflers for possible

leakage and cracks.

3. Periodically ordaily, drain moisture from conden-

sation traps.

4.

Inspect air shrouds for leaks and security. Besure

cooling fins are clean.

5. Inspect electrical wires and connections for

security and fray damage.

If generator requires major repair or

servicing,

contact an authoriz-

ed Onan dealer or distributor.

AC

GENERATOR

Periodic inspections that coincide with engine oil

changes will ensure good performance.

BEGIN SPEC AA.

When inspecting the rotating rectifier assembly,

make sure diodes are free of dust, dirt and grease.

Excessive foreign matter on these diodes and heat

sinks will cause the diodes to overheat and will result

in their failure. Blow out the assembly periodically,

with filtered, low pressure air. Also check to see that

diodes and leadwires are properly torqued. The

diodes should be torqued to 25 in. Ib. or finger tight

plus a quarter

turn.

See Figure 1.

BATTERIES

Check the condition of the starting batteries at least

every two weeks. See that connections are clean and

tight. A light coating of non-conductive grease will

retard corrosion at terminals. Keep the electrolyte at

the proper level above the plates by adding distilled

water. Check specific

g

ravity; recharge if below

1.280.

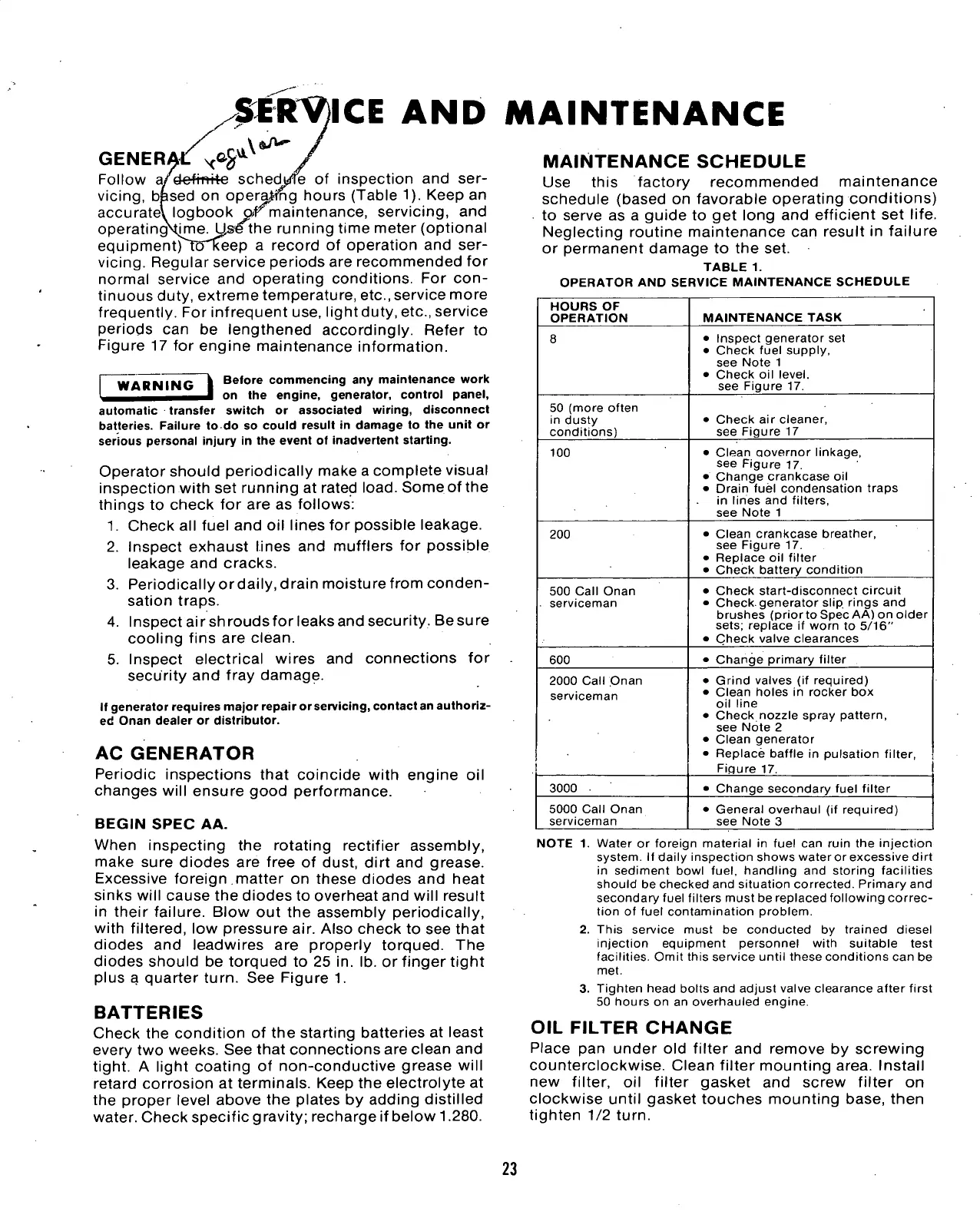

MAINTENANCE

SCHEDULE

Use this factory recommended maintenance

schedule (based on favorable operating conditions)

to serve as a guide to get long and efficient set life.

Neglecting routine maintenance can result in failure

or permanent damage to the set.

TABLE 1.

OPERATOR AND SERVICE MAINTENANCE SCHEDULE

HOURS OF

OPERATION

MAINTENANCE TASK

8

• Inspect generator set

• Check fuel supply,

see Note 1

• Check oil level,

see Figure 17.

50 (more often

in dusty

conditions)

• Check air cleaner,

see Figure 17

100

• Clean qovernor linkage,

see Figure 17.

• Change crankcase oil

• Drain fuel condensation traps

in lines and filters,

see Note 1

200

• Clean crankcase breather,

see Figure 17.

• Replace oil filter

• Check battery condition

500 Call Onan

. serviceman

• Check start-disconnect circuit

• Check, generator slip, rings and

brushes (priorto Spec AA) on older

sets;

replace if worn to 5/16"

• Check valve clearances

600

• Change primary filter

2000 Call Onan

serviceman

• Grind valves (if required)

• Clean holes in rocker box

oil line

• Check nozzle spray pattern,

see Note 2

• Clean generator

• Replace baffle in pulsation filter,

Figure 17.

3000 • • Change secondary fuel filter

5000 Call Onan

serviceman

• General overhaul (if required)

see Note 3

NOTE 1. Water or foreign material in fuel can ruin the injection

system.

If daily inspection shows water or excessive dirt

in sediment bowl

fuel,

handling and storing facilities

should be checked and situation corrected. Primary and

secondary fuel filters must be replaced following correc-

tion of fuel contamination problem.

2.

This service must be conducted by trained diesel

injection equipment personnel with suitable test

facilities. Omit this service until these conditions can be

met.

3. Tighten head bolts and adjust valve clearance after first

50 hours on an overhauled engine.

OIL FILTER

CHANGE

Place pan under old filter and remove by screwing

counterclockwise. Clean filter mounting area. Install

new filter, oil filter gasket and screw filter on

clockwise until gasket touches mounting base, then

tighten 1/2

turn.

23

Loading...

Loading...