5 Installation

−14−

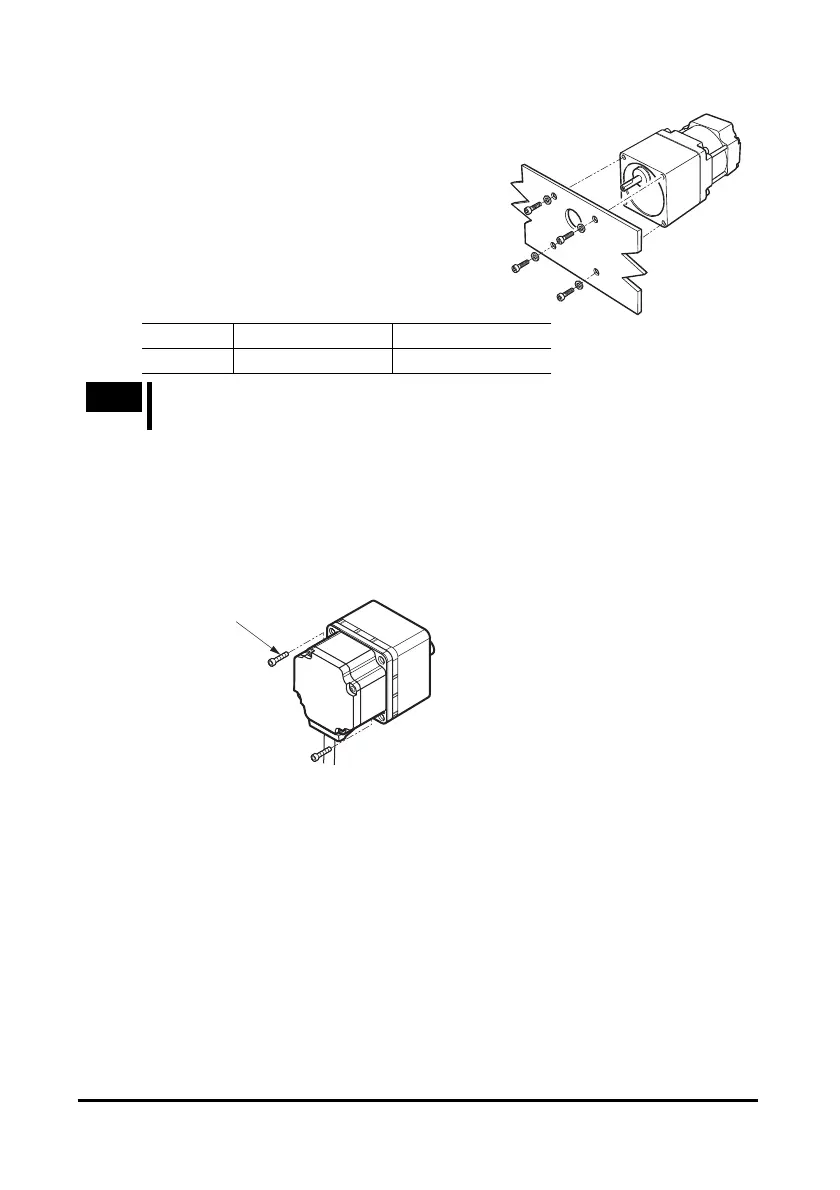

• Geared type

To install the motor, use the four installation

holes and mount the motor with four bolts (not

provided) so that there is no gap with the

mounting plate.

Effective depth of bolt: 8 mm (0.31 in.)

Unit model Nominal thread size Tightening torque

BLH015 M4 1.8 N·m (15.9 lb-in)

Note

Fit the boss on the gearhead mounting surface into a counterbore or through

pilot-receiving hole.

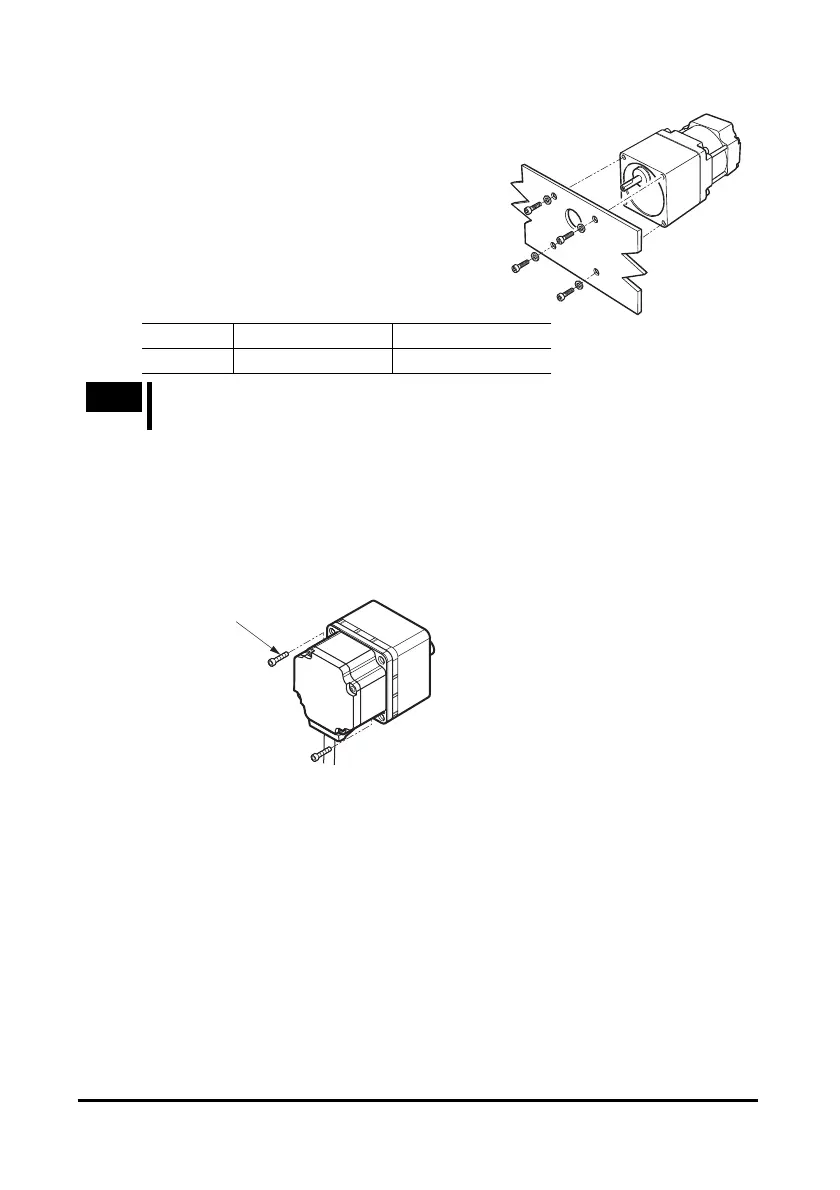

Changing the motor cable’s routing direction

The gearhead can be removed and the motor cable position changed to a desired 90°

direction. (BLH015 is removed)

1. Remove the hexagonal socket head screws (2 pcs.) assembling the

motor and gearhead and detach the motor from the gearhead.

Hexagonal socket head

screws

2. Using the pilot sections of the motor and gearhead as guides, install the

motor to the gearhead and tighten the hexagonal socket head screws.

At this time, the motor cable position can be changed to a desired 90° direction.

When installing the gearhead, slowly rotate it clockwise/counterclockwise to

prevent the pinion of the motor output shaft from contacting the side panel or

gear of the gearhead.

Also, confirm that no gaps remain between the motor flange surface and the end

face of the gearhead’s pilot section.

Loading...

Loading...