9 Troubleshooting and remedial actions

−49−

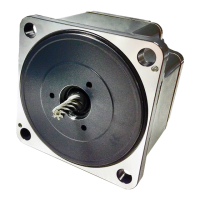

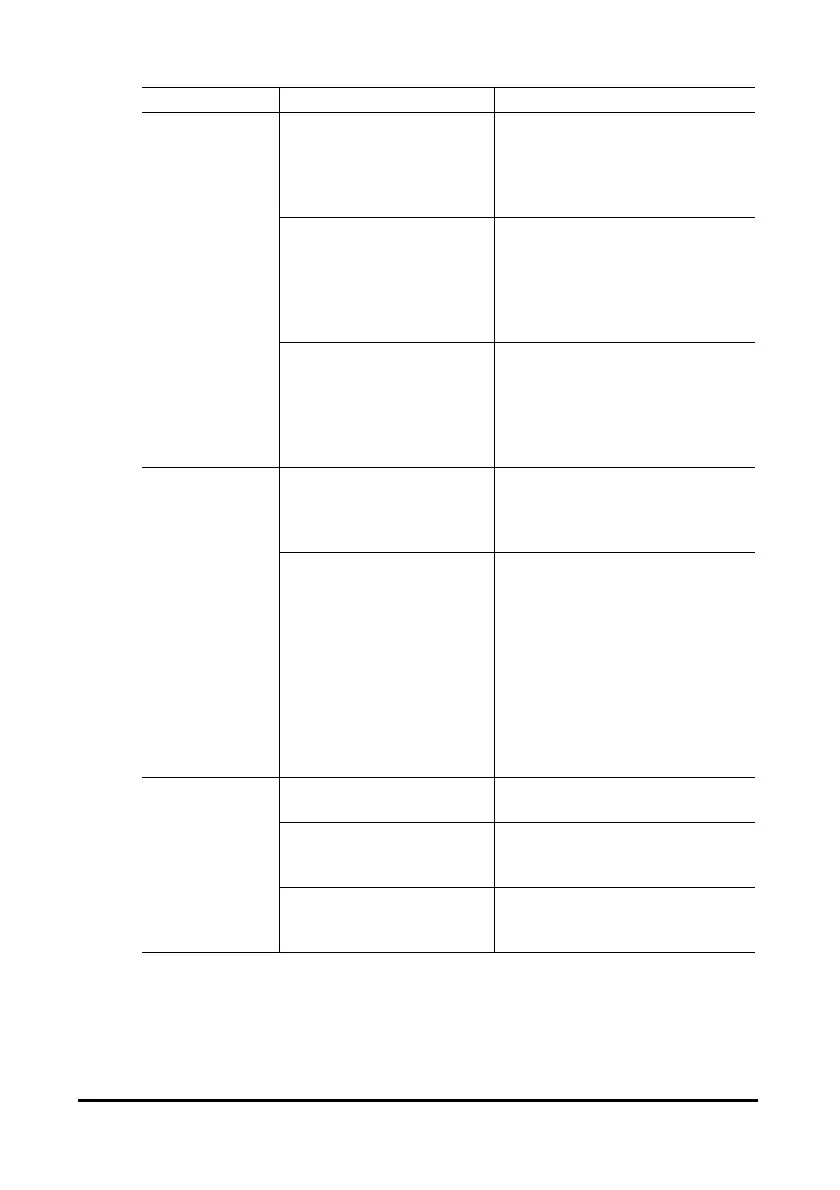

Phenomenon Estimated cause Measure

Incorrect CW/CCW input or

faulty connection.

The motors driven in the CW

direction when the CW/CCW input

is set to the ON. CCW direction

when the CW/CCW input is set to

the OFF.

Speed reduction ratios 30:1,

50:1 and 100:1 are used in

the combination type

parallel shaft gearhead, or

20:1 and 30:1 are used in

the geared type.

When these speed reduction

ratios are used, drive direction is

opposite to that of the motor.

Reverse the CW/CCW input

operation.

The motor is

driven opposite

of the specified

direction.

A combination type hollow

shaft gearhead is used.

With a combination type hollow

shaft flat gearhead, the rotating

direction will vary depending on

whether the motor unit is viewed

from the front or rear of the

gearhead (P.40).

The motor (gearhead)

output shaft and load shaft

are not aligned with each

other.

Make sure that the motor

(gearhead) output shaft and load

shaft are connected in an

appropriate manner.

• The motor

does not run.

• Motor

vibration too

great.

Affected by noise.

Check for running only with the

motor, driver and external

potentiometer required for running.

If noise influence has been

confirmed, take the appropriate

measures such as separation from

noise generating source,

re-connection of wiring,

replacement of the signal cable by

a shielded cable, and installation

of a ferrite core.

The motor is stopped by

START/STOP input.

Stop the motor by RUN/BRAKE

input.

Load inertia may be

excessive.

For this check, increase the

frictional load or reduce the load

inertia.

The motor fails

to stop

instantaneously.

The deceleration time is too

long.

Check the setting of the

acceleration/deceleration time

potentiometer.

Loading...

Loading...