HP-4189-2

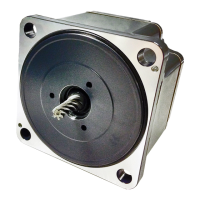

5-Phase Stepping Motor Unit

CRK Series

OPERATING MANUAL

Thank you for purchasing an Oriental Motor product.

This Operating Manual describes product handling procedures and safety precautions.

• Please read it thoroughly to ensure safe operation.

• Always keep the manual where it is readily available.

Table of contents

1

Introduction .................................. 2

2 Safety precautions ....................... 4

3 Precautions for use ...................... 7

4 Preparation................................. 10

4.1 Checking the product ................10

4.2 Combinations of motors and

drivers .......................................10

4.3 Names and functions of parts ...13

5 Installation.................................. 15

5.1 Location for installation .............15

5.2 Installing the motor.................... 15

5.3 Installing a load .........................17

5.4 Permissible overhung load and

permissible thrust load .............. 17

5.5 Installing the driver....................19

5.6 Installing and wiring in compliance

with EMC Directive.................... 21

6 Connection..................................24

6.1 Connection example................. 24

6.2 Suitable contacts and

connector housings .................. 27

6.3 Connecting the power supply ... 29

6.4 Explanation of I/O signals......... 29

6.5 Timing chart.............................. 33

7 Setting.........................................34

7.1 Step angle ................................ 34

7.2 Pulse input modes.................... 36

7.3 Smooth drive function............... 36

7.4 Motor current ............................ 37

8 Inspection....................................42

9 Troubleshooting and remedial

actions ........................................43

10 Options (Sold separately)............46