11OrionWelders.com

WHEN TO FLATTEN/BLUNT THE ELECTRODE

When working with silver, copper, and other highly conductive metals in energy levels above 20ws, it is

recommended to blunt the electrode instead of sharpening it.

• Completely remove the electrode from the stylus.

• Pinch the electrode between the thumb and middle finger with the point facing inward.

• Turn the Dremel or flex shaft on then hold it with the opposite hand. *Place the electrode tip in the diamond

disc in such a way that the grit of the disk is moving parallel with the electrode shaft and moving towards the

tip.

• is will affect the quality of the weld if not done as explained above.

• Set the electrode on the diamond disk at a 10-degree angle and begin to spin the electrode with the thumb

and middle finger. *A helpful way to get a sharp electrode is to push down on the electrode with your index

finger while twisting the electrode with the thumb and middle finger.

• Once the electrode is sharp and clean, turn the electrode to a 90-degree angle and push it against the

dremel in order to place a flat/blunt tip on the electrode.

• Once the electrode has a flat/blunt tip, turn the Dremel off and insert the electrode back into the stylus as

explained above.

Shielding Gas Setup

During the pulse-arc welding process high temperature plasma quickly melts metal into a molten pool. As the weld is

performed, a small amount of shielding gas is released through the weld stylus to prevent oxygen from entering the molten

pool. After the weld has occurred the protective gas turns off.

If oxygen from the air enters this molten pool, the result is a metal oxide that is brittle, porous and burnt-looking. Protective

shielding gas is used, such as 99.996% pure Argon (Argon 4.6) or higher, to prevent these effects. Shielding gas is necessary

to produce clean and repeatable pulse-arc welds. We recommend high purity argon. is can be purchased at your local

welding supply shop.

PRESSURIZED GAS SAFETY

ere are several important rules that should be followed when using a compressed shielding gas such as argon.

• Always secure the pressurized gas tank to a fixed location (such as a sturdy table leg).

If the pressurized gas cylinder were to tip and become damaged there is possibility

that the tank could become rocket-like, expelling the high pressure shielding gas as

propellant.

• Always turn off the shielding gas at the main valve when finished. is will help your

shielding gas supply last longer in case there is a small leak in the tubing. is is also a

good safety practice. If the tube becomes dislodged shielding gas could fill the room

and displace oxygen, which can lead to suffocation. Argon is heavier than air and will fill

the room from the bottom upward. If you experience a large shielding gas leak, open all

of the doors and windows in the room.

SHIELDING GAS TANK AND REGULATOR SETUP

• Ensure that your shielding gas tank is securely fastened to a stationary point near

the welding area.

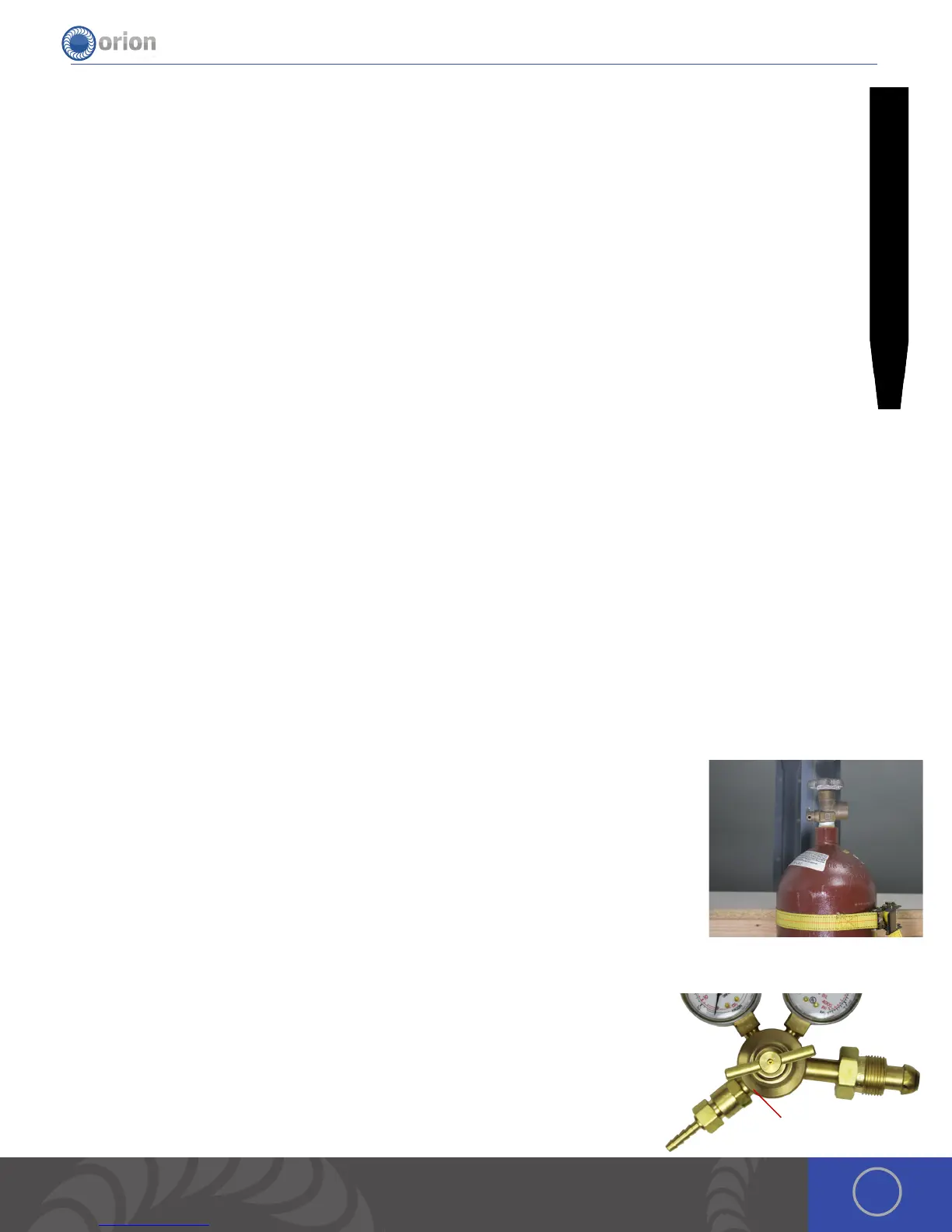

• Turn the regulator dial COUNTER CLOCKWISE (closed) until it is fully backed out.

meaning the dial become loose, to prevent over-pressurization of the line.

Regulator Dial

Loading...

Loading...