38

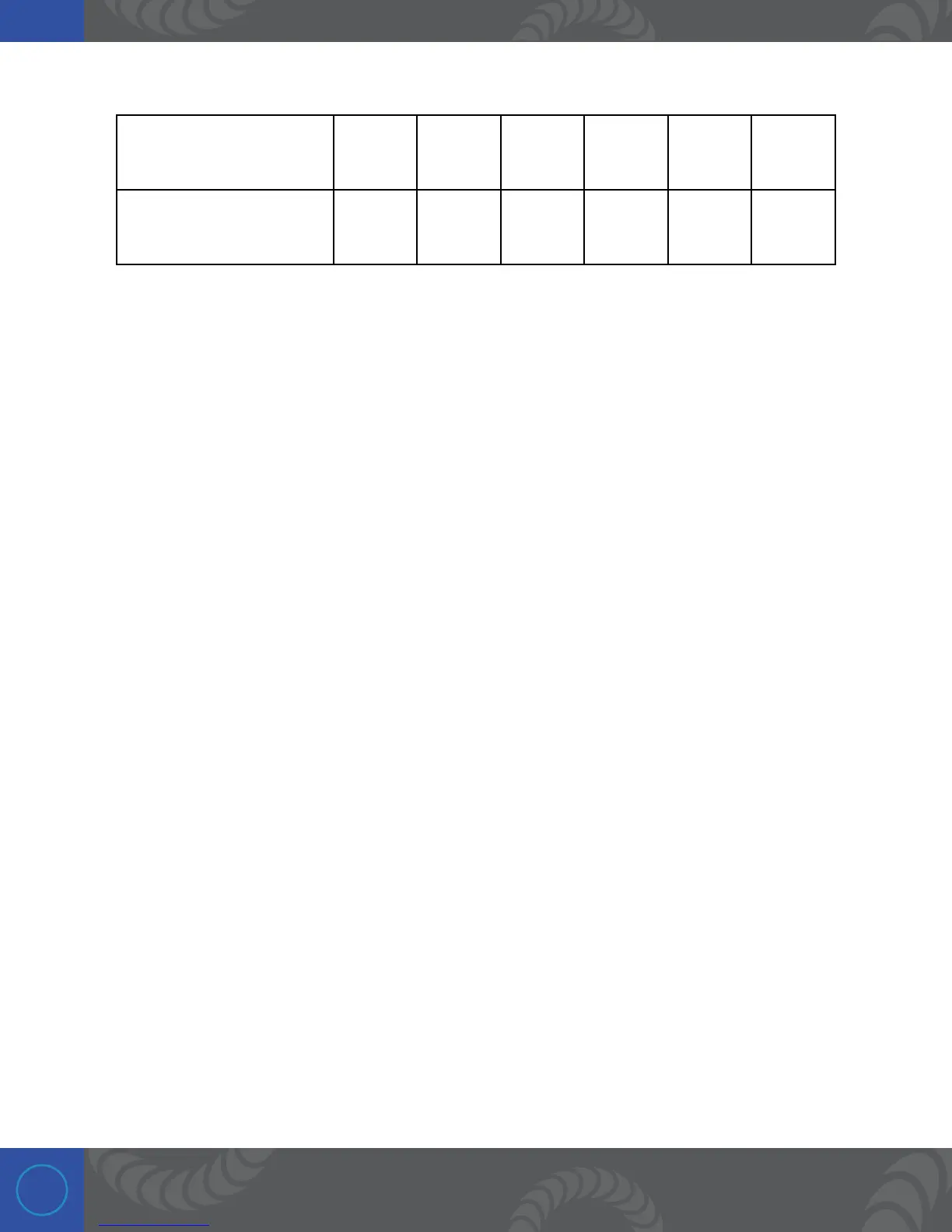

CNC EV Compression Force Table

Chapter 8: Welding Tips and Tricks

Electrode

MAINTENANCE

e condition of the electrode tip can greatly affect weld quality. As weld slag and oxidation builds up on

the electrode, the weld spots can become erratic in size and shape and the arc generation can be affected.

• Keep the tip as clean as possible throughout the weld process.

• Ignition settings can be tweaked to help prevent tip erosion and contamination during the welds

(refer to Ignition Section).

• Periodically check the electrode during the first weld cycles of a new weld application to establish a

baseline for the number of welds that can take place before the tip needs attention. It is a good idea

to make electrode maintenance part of the SOP for the weld process.

TIP SHAPE

e geometric shape of the electrode can have an effect on weld penetration and quality, depending on

the metals being welded and the application .

• Flat Tip - A perfectly flat tip is useful when welding “splashy” metals such as silver and aluminum.

Typically, metals that flow well when molten are best suited for a flat tip.

• Tapered Tip - e tip can be tapered into a flat to help focus the energy for more penetration and

better arc starts, but continue to minimize expulsion during a weld.

• Sharp Tip - Sharp tips are ideal for applications that need high weld penetration depth, or for

increased arc start capability. e sharper the tip, the easier it is to start the arc. If welds are

continually missed throughout a weld cycle, try sharpening the tip.

COMPRESSION

DISTANCE

1/8” 1/4” 3/8” 1/2” 5/8” 3/4”

RESULTING SPRING

FORCE

1.5 3 4.5 6 7.5 9

Loading...

Loading...