46

Maintenance

6.8.2 pH Integrated Sensor

6.9 Temperature Sensor Maintenance

Use soap or rubbing alcohol to remove grease, oil, or biological growth and rinse with

water. Do not use any objects to poke the sensor or the transducer membrane will rupture.

6.10 Pressure Sensor Maintenance

1. If calcium deposits are forming in the port, squirt vinegar into the pressure sensor port

with a syringe and soak overnight.

2. Soap or rubbing alcohol may be used to remove grease, oil, or biological material.

Rinse with water. Do not use any objects to poke the sensor or the transducer

membrane will rupture.

6.11 Other Sensor Maintenance

Refer to the sensor specific instruction sheet for more information.

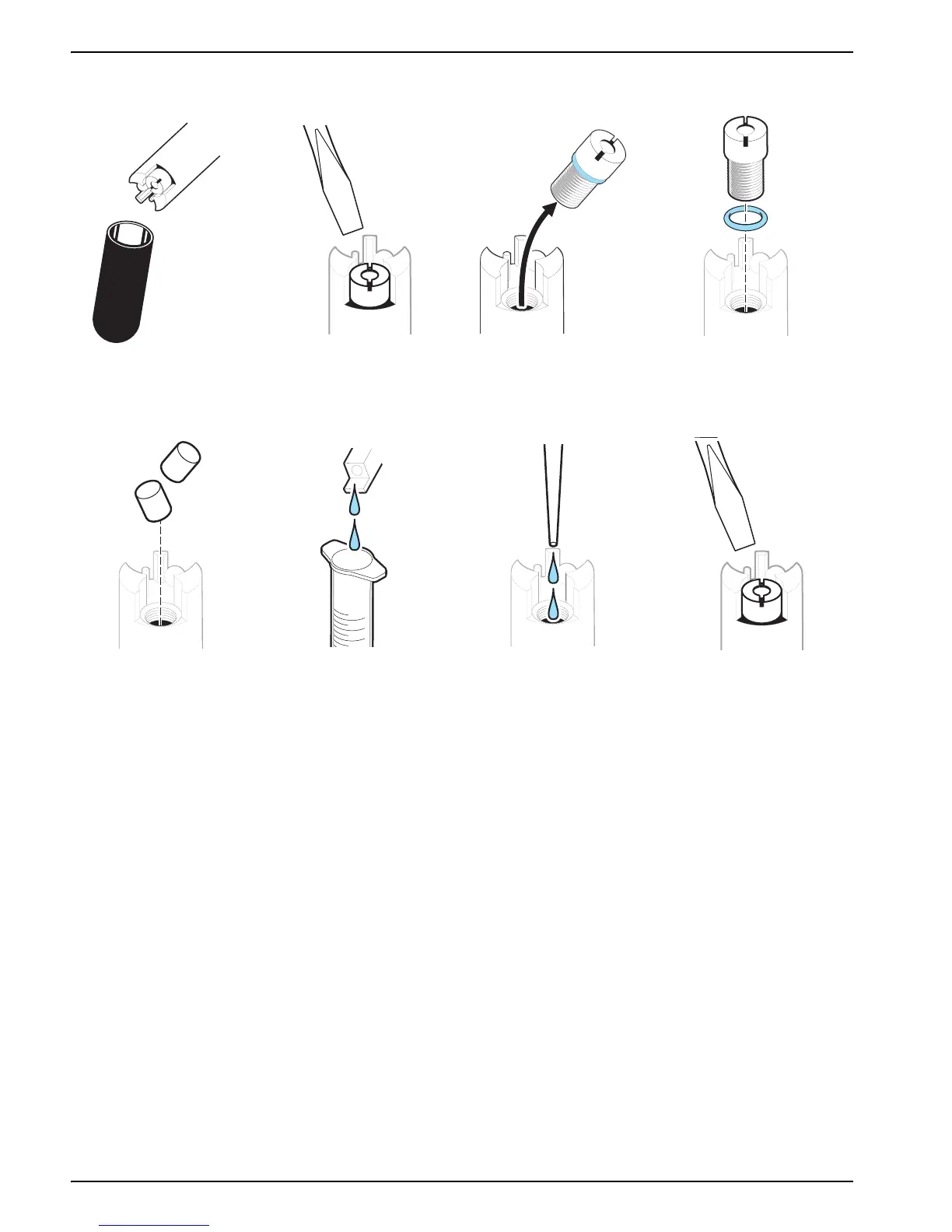

1. Remove the plastic

soaking cap. Save the

cap for reuse.

2. Use the supplied

screwdriver to loosen

the Teflon

®

Reference Junction.

3. Remove the Teflon

Reference Junction

and discard if dirty or

clogged.

4. Replace the blue O-ring

located below the Teflon

Reference Junction if it

is damaged or loose.

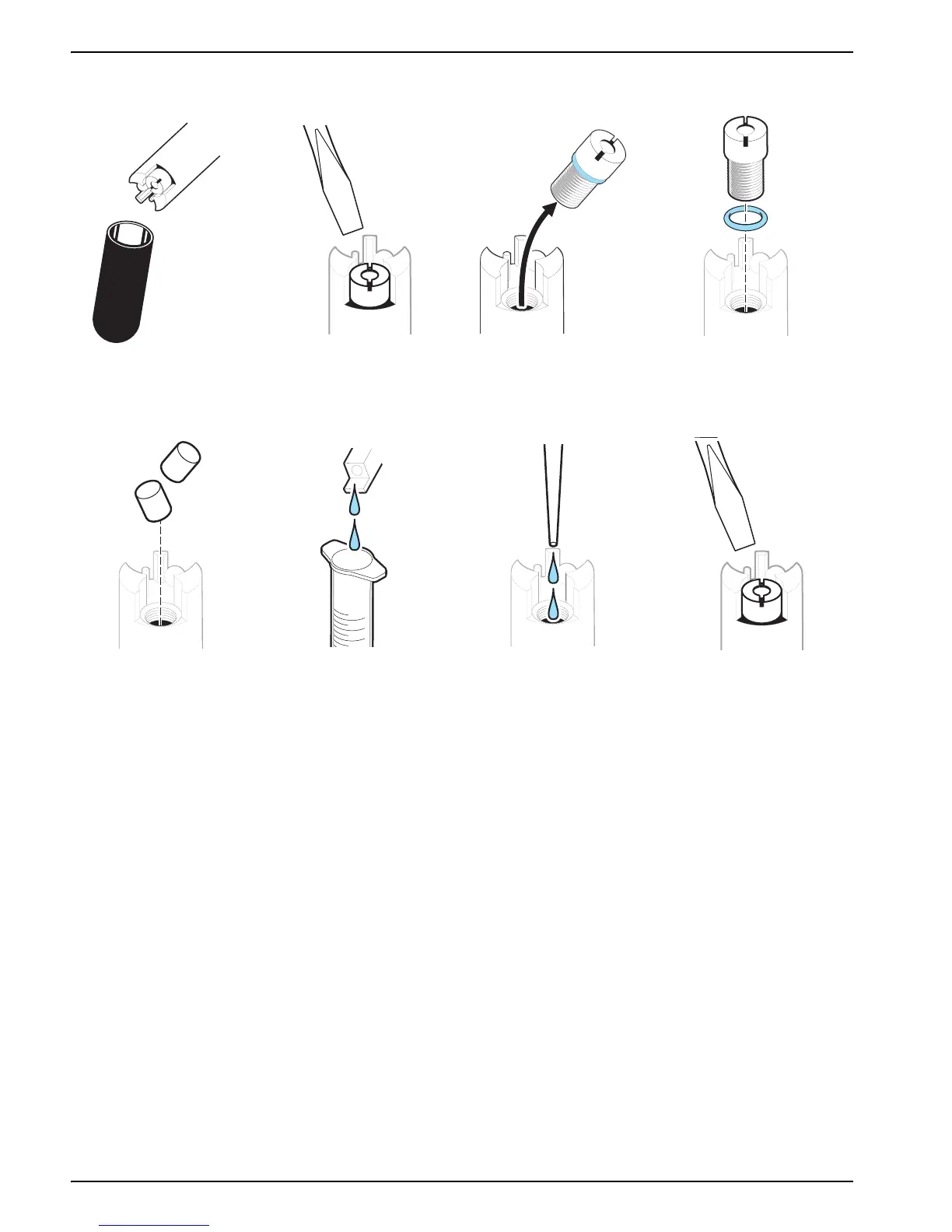

5. Drop two KCI salt pellets

(Cat. No. 00537HY) into

the reference opening.

6. Inject the pH reference

electrolyte into the

supplied plastic syringe.

7. Refill the reference

opening with electrolyte.

8. Use the supplied

screwdriver to install

the new Teflon

Reference Junction

(Cat. No. 002770HY).

Loading...

Loading...