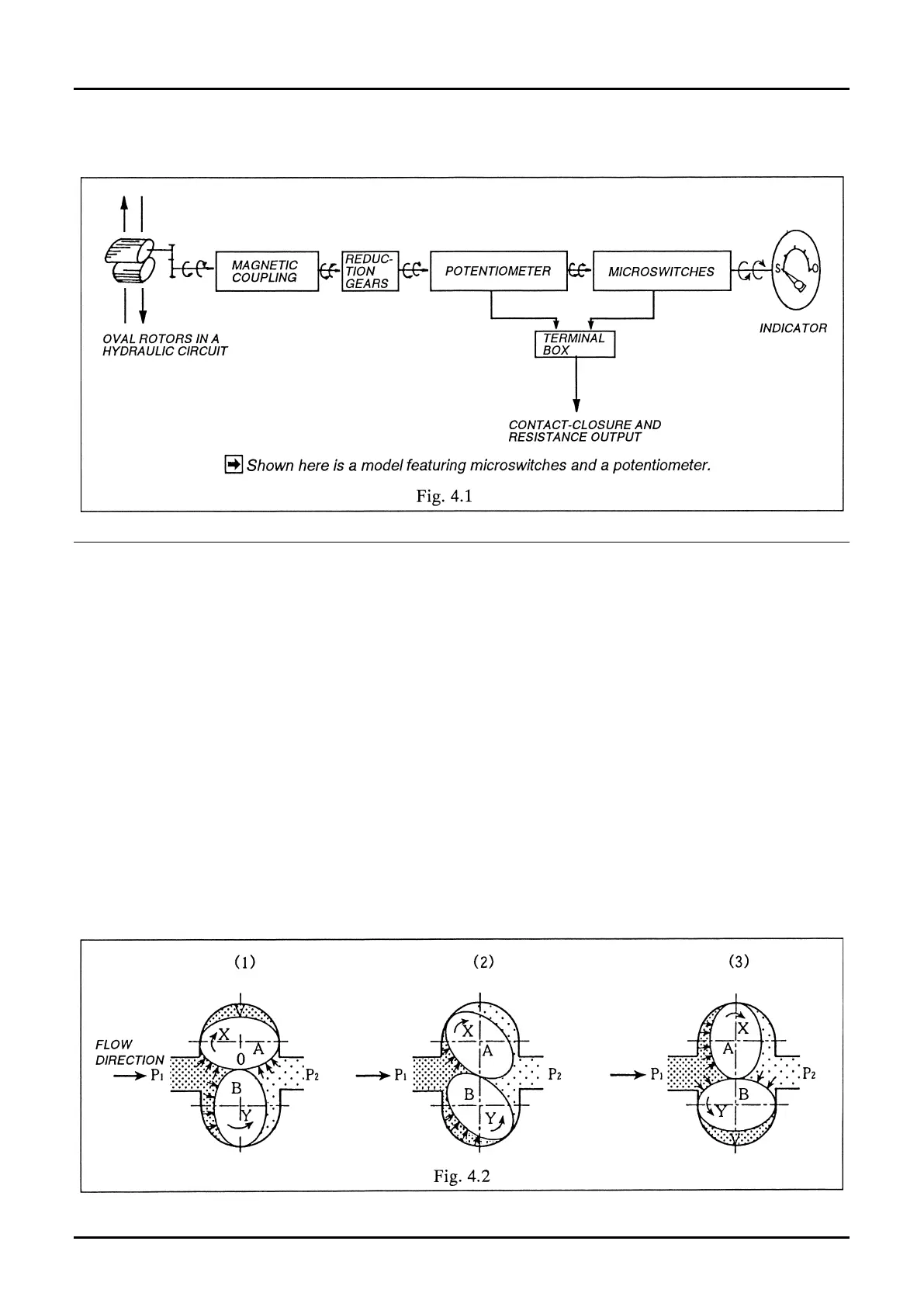

(1) Two Oval rotors are used in the wetted measuring chamber in contact with the fluid as shown in the

diagram below. Assume that the inlet pressure is P

1

and the outlet pressure P

2

. Pressure P

1

is uniformly

distributed over the entire teeth on its side P

1

; no torque acts on rotor B. Regarding rotor A, on the other

hand, pressures P

1

and P

2

act on its inlet tooth area (area “a”) and its outlet area (area “a”), respectively,

separated at a parting point “0” at which the two rotors mesh. Since their pressure relationship is P

1

>P

2

,

the resulting rotational dierential force represented by a・P

1

>a・P

2

acts on rotor A, forcing it to turn in the

arrow direction “X.” At a 90° displaced position, then, rotors A and B alternate places with each other; rotor

B is forced to turn in the arrow direction “Y.” This motion continues without coming across a dead point as

long as the process ow is maintained.

(2) Liquid is precisely quantied by a crescent-shaped cavity (V) formed by the chamber wall and Oval rotors.

The amount (q) of uid carried in every rotation of the Oval rotor is four times the crescent-shaped pocket

“V.”

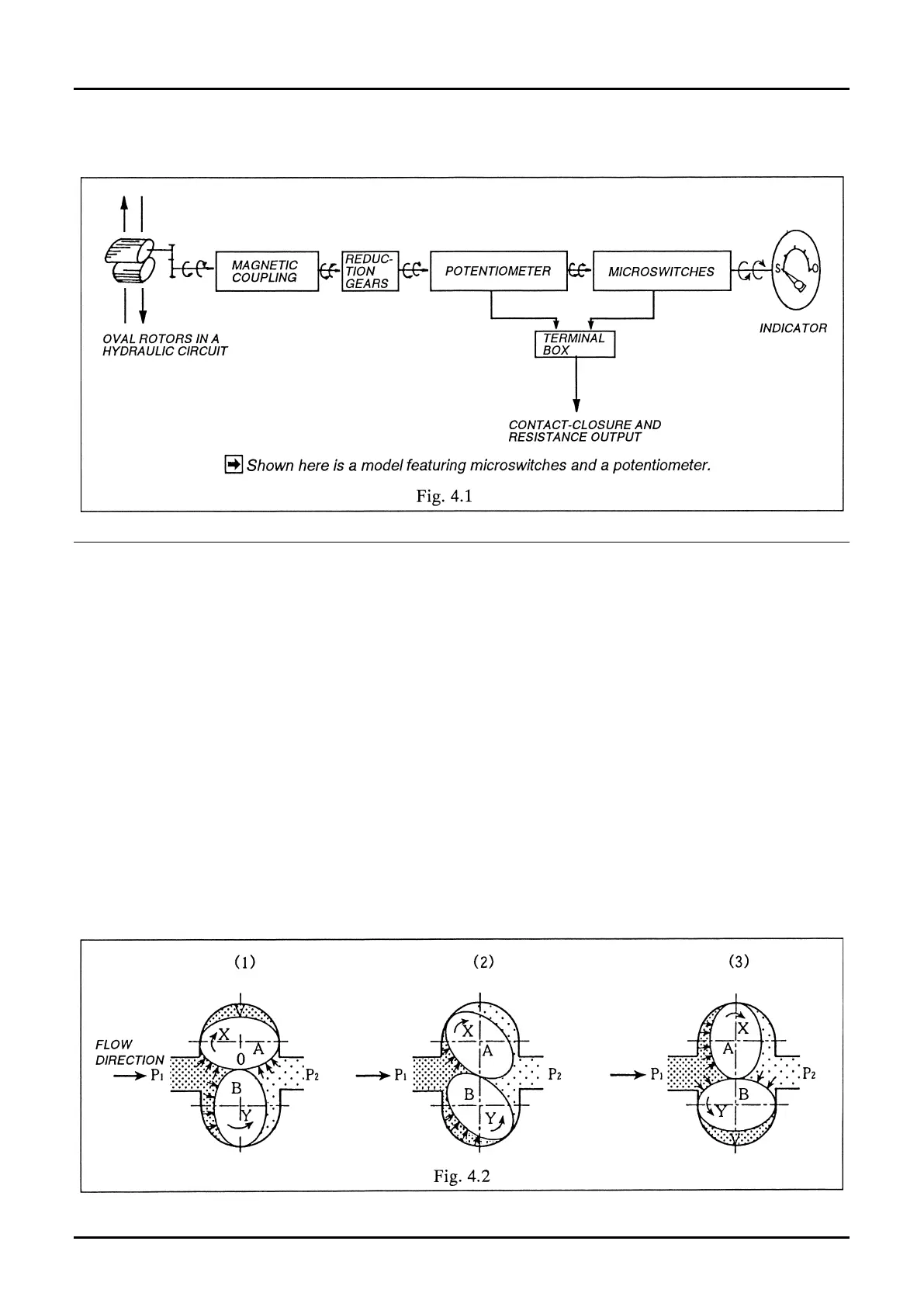

(3) This turning eort of Oval rotors is transmitted to the indicator through a magnetic coupling, reduction

gear train, and potentiometer/microswitch arrangement. The volume of uid passing across the measuring

chamber is determined in this way, allowing the valve position to be displayed on the indicator.

Loading...

Loading...