① Check to see that the controller, such as the

valve, is operating properly. As long as the uid

is running, the nonuniform rotating sound of

Oval rotors should be heard. To make sure of it,

repeat opening and shutoff of the valve, or

other controller, several times.

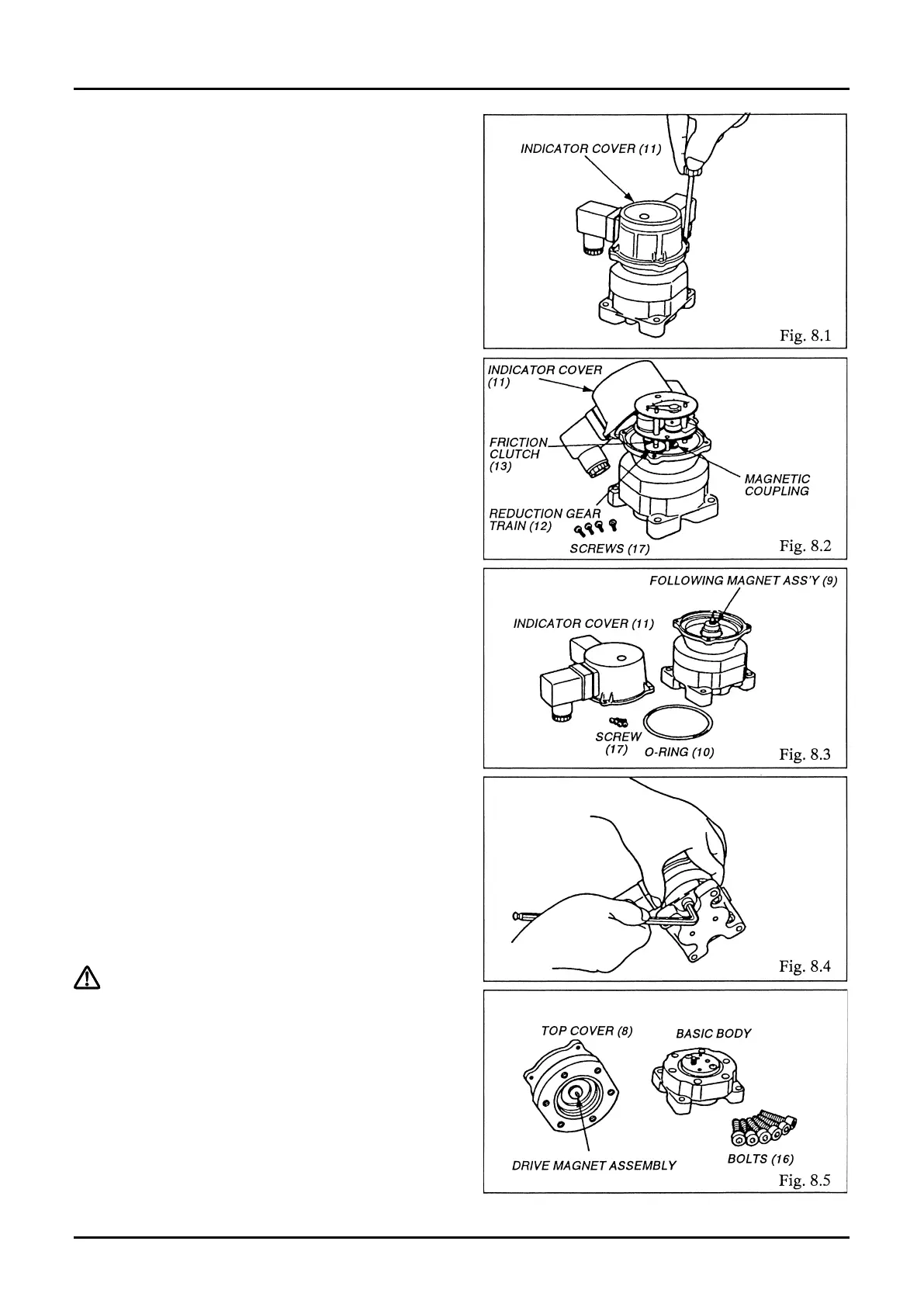

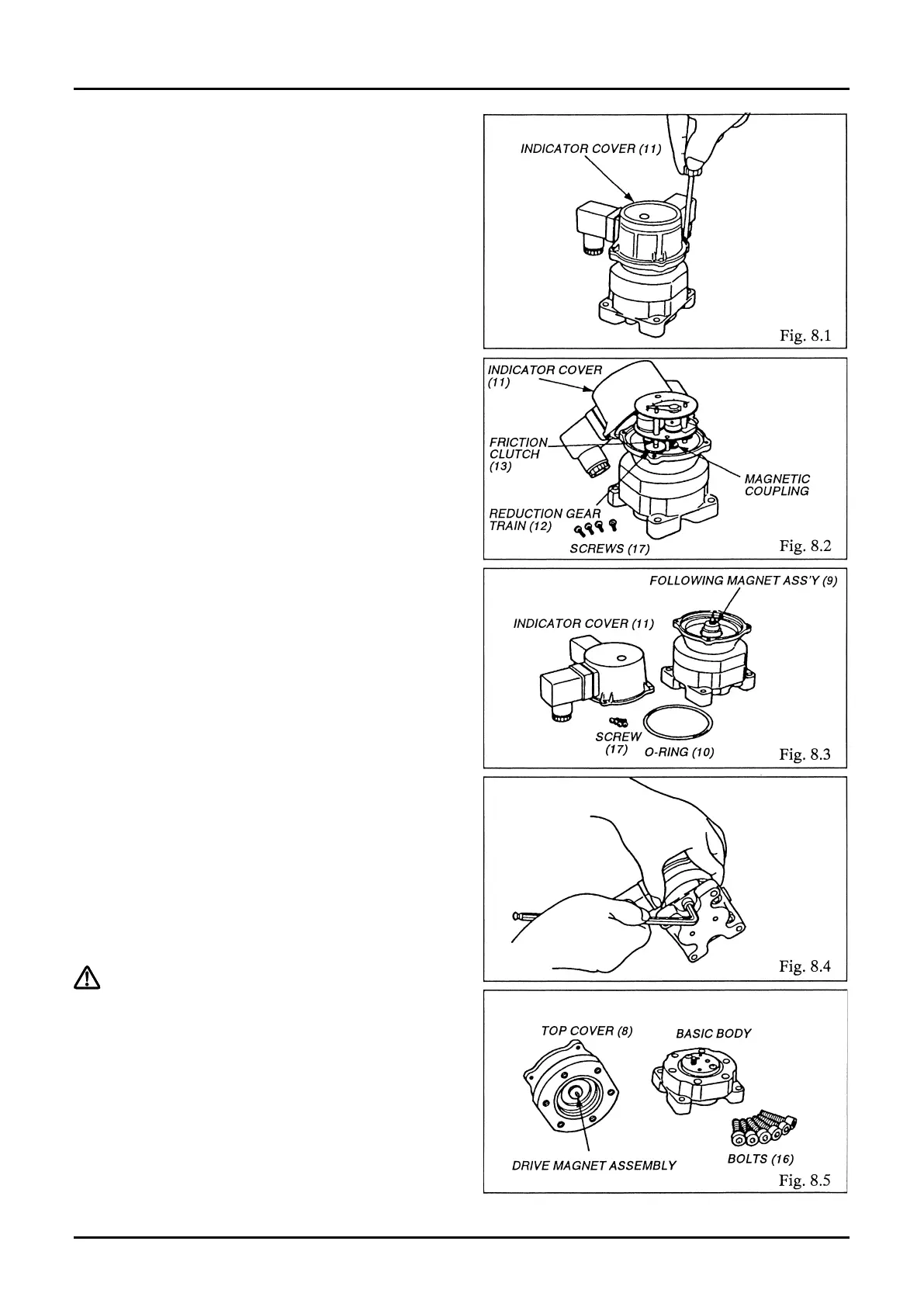

② If nonuniform rotating sound is audible but the

pointer will not move (nor any electrical signal

output), trouble is suspected in the friction

clutch (13), reduction gear train (12), or

magnetic coupling (9). If this is the case, take o

four M3 screws (17) and remove the indicator

cover (11) (Fig. 8.1).

Allowing the hydraulic uid to ow in this state,

make sure to see that gears in the reduction

gear train (12) are moving (Fig. 8.2).

③ If, despite a hydraulic fluid flow, the reduction

gear train fails to move.

Taking off four M3 screws (17), remove the

indicator cover (11) and make sure of the

rotation of the following magnet assembly (9)

(Fig. 8.3).

If it is found all right, trouble is attributable to

the members in contact with the uid. If this is

the case, reduce the line pressure to zero.

④ Ensure that the hydraulic pressure has dropped

to zero and then remove the valve position

indicator from the hydraulic line.

⑤ Taking o six bolts (16), separate the top cover

(8) of basic body (Fig. 8.4).

⑥ Make sure of freely rotation of the driving

magnet assembly (5) (Fig. 8.5).

⇨Continued on next page.

Loading...

Loading...