4

Sensor Technology

28

Subject to change without notice

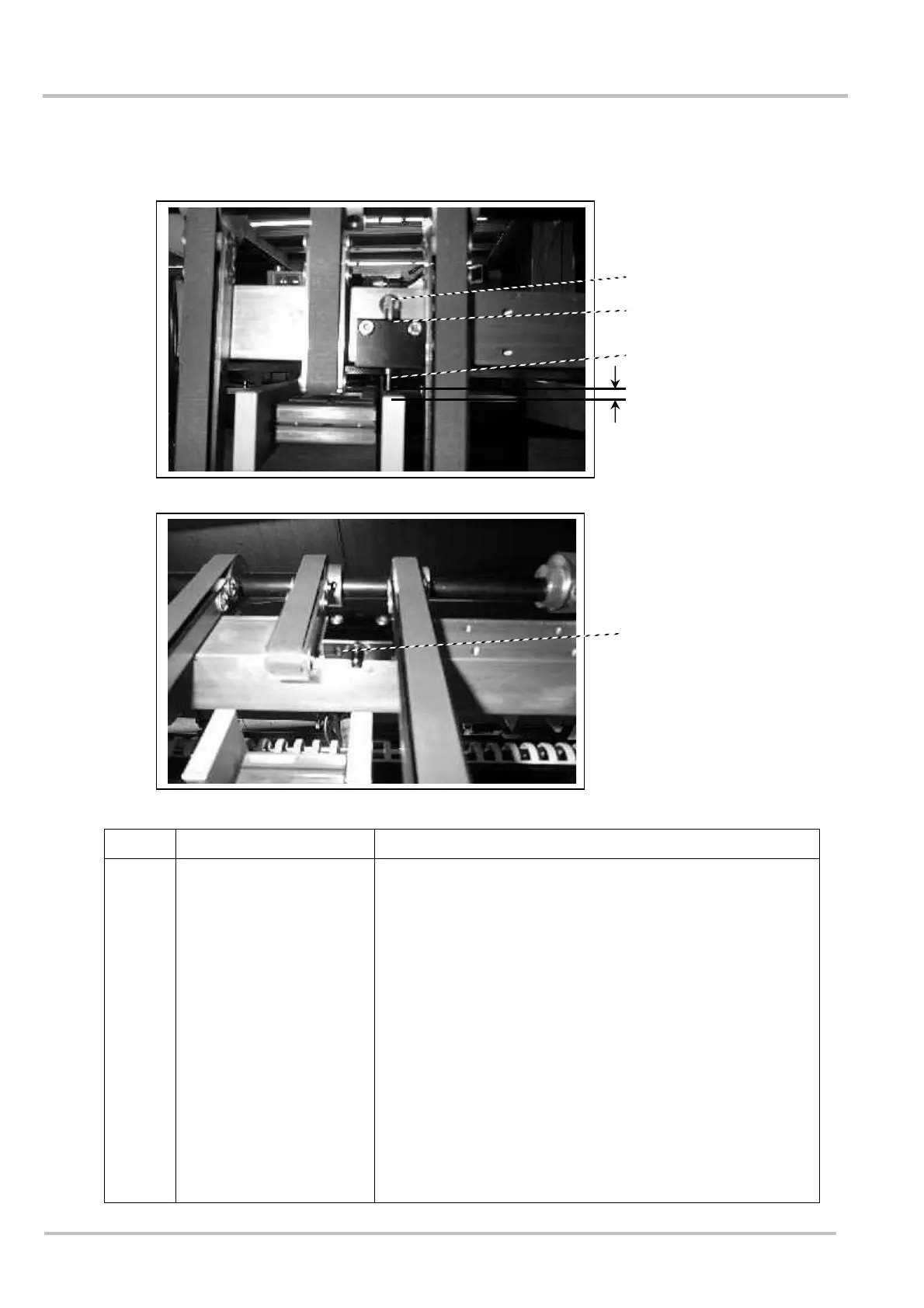

4.4 Sensor B 5

Sensor Position/Name Adjustment

B5 Batch pressure The plunger must be adjusted using the grub screw so

that the distance A between the plunger and the pressing

bar is 1-2mm. N.B. Set the adjusting frame to its largest

format and check if measurement A is correct with

pressing bar both retracted and extended.

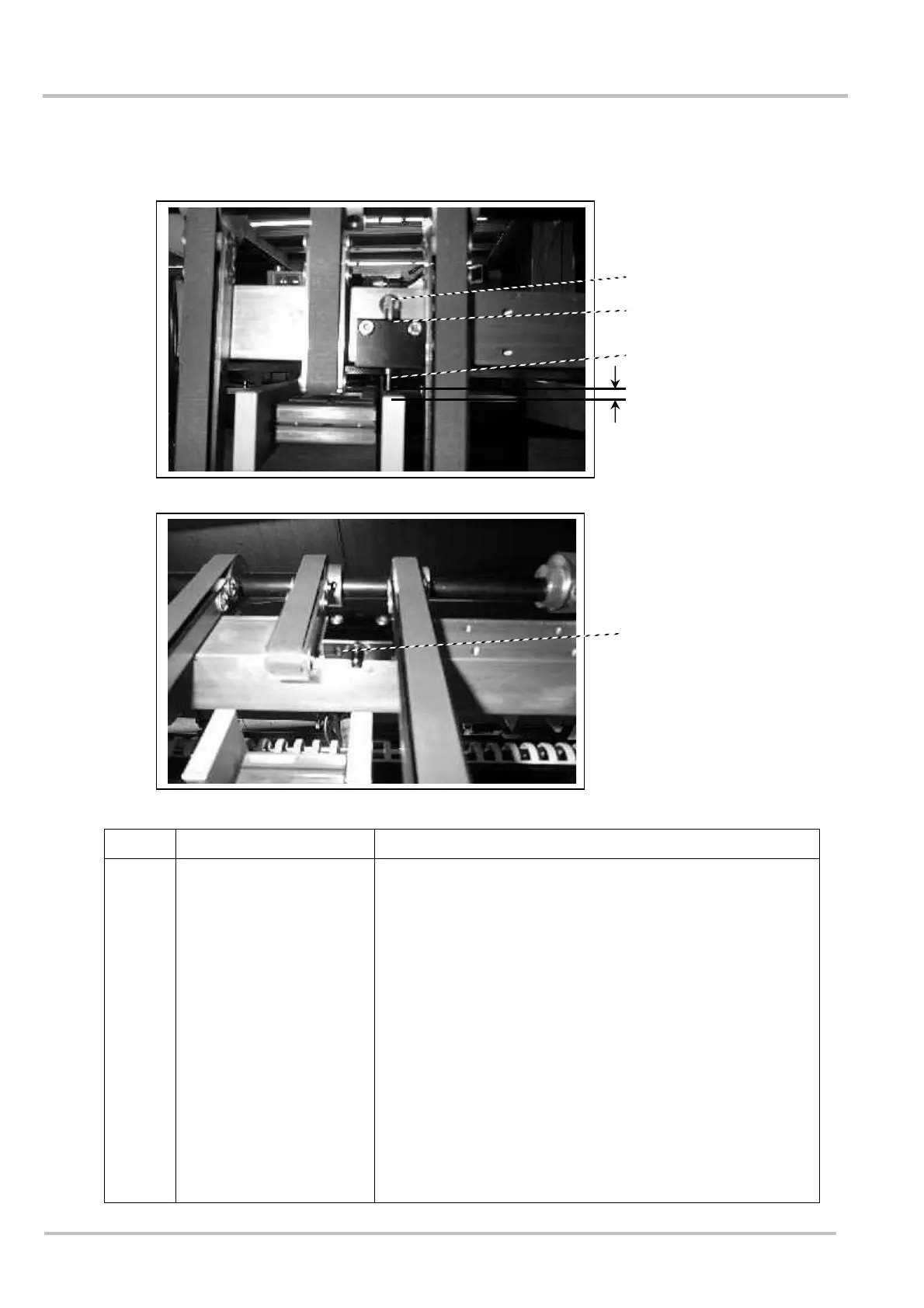

Start the packaging process with one bundle in the

middle shaft and stop it using the stop button as the

bundle is being pressed.

Call up sensor B5 via code 203. Keep turning adjusting

screw (cylinder head cap screw) clockwise until the

display shows 0.

Unscrew the cylinder head cap screw anti-clockwise until

1 appears on the display. Now unscrew the cylinder head

cap screw a further full turn anti-clockwise.

Grub screw

Plunger

Adjustment screw

B5

A

Loading...

Loading...