14

u

Procedure G — Test the Integrity of the Cadence ILC Module

This procedure includes steps to test the Cadence setup for leaks.

Follow these steps to test the integrity of the Cadence ILC module:

1. Open the feed and permeate 2 lines and close the retentate and permeate 1 line.

2. Direct the permeate line to collection vessel or drain.

3. Restart the system pump or reopen the compressed air source and adjust to maintain a feed

pressure of:

– Delta membranes: 4.1 barg (60 psig)

– Omega membranes: 2.1 barg (30 psig)

CAUTION!

Do not exceed the pressure rating of the tubing during operation or integrity

testing. Tubing that is rated to at least 4.1 bar (60 psi) should be used.

4. Measure the air flow out of the permeate port using the Pall Flowstar integrity tester or other

integrity test equipment.

5. If the flow from the permeate port is less than the values stated in Table 3,

the Cadence ILC module is integral. If the flow from the permeate port is greater than

these values, the module has failed the integrity test. If a module fails the integrity test, please

contact Pall for further assistance.

6. Stop the compressed air source or pump and gradually depressurize the module by slowly

opening the retentate line valve.

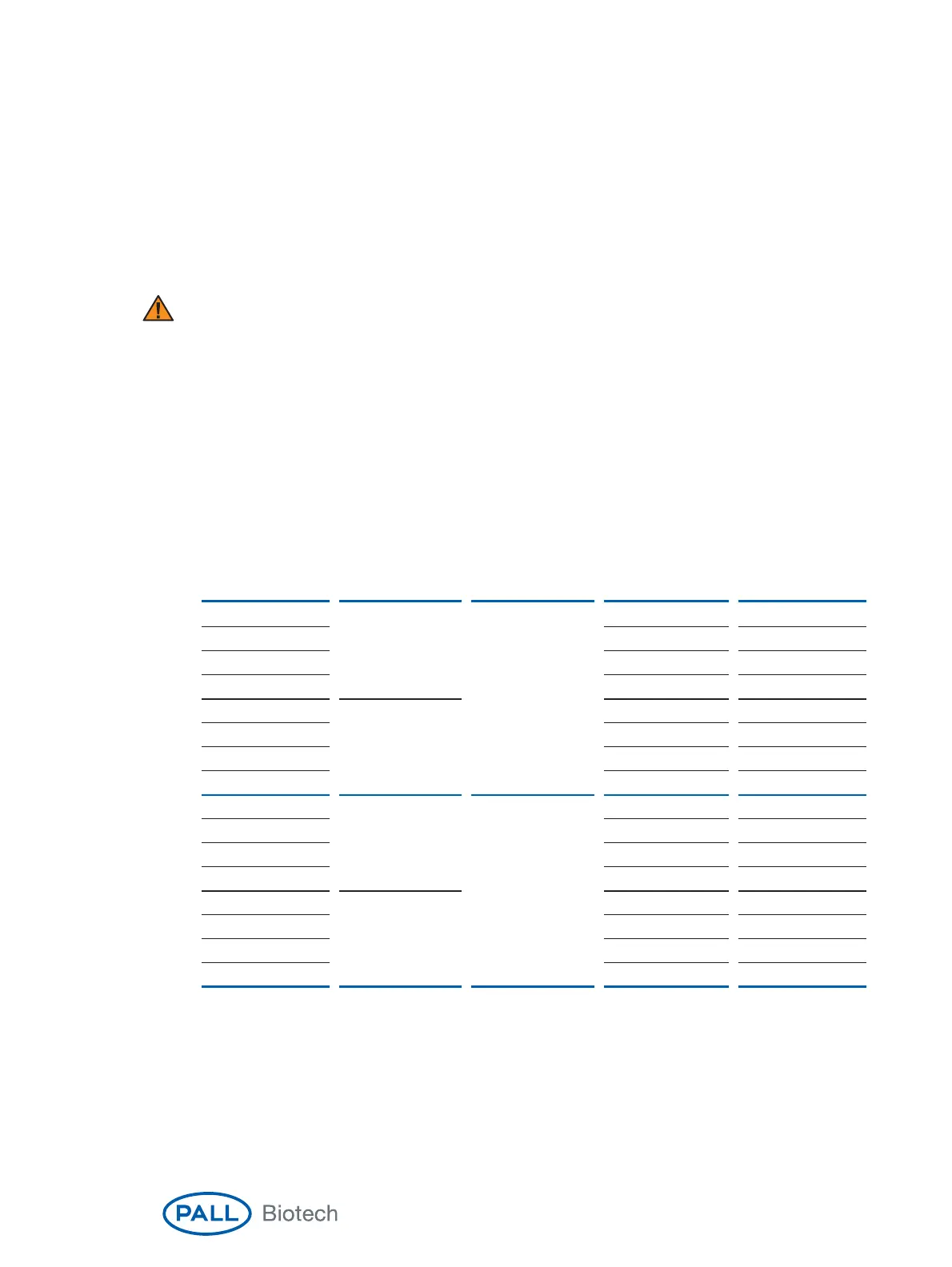

Table 3

Integrity test parameters for Cadence ILC devices

Forward Flow Limit

Part Number Membrane Type Test Pressure Filter Area

(m

2

)

(sccm)

ILD010T010407 Delta, 10 kDa 4.1 barg (60 psig) 0.065 35

ILD010T020407 0.13 70

ILD010T120407 0.7 380

ILD010T060407 3.5 1900

ILD030T010407 Delta, 30 kDa 0.065 35

ILD030T020407 0.13 70

ILD030T120407 0.7 380

ILD030T060407 3.5 1900

ILOS010T010407 Omega, 10 kDa 2.1 barg (30 psig) 0.065 100

ILOS010T020407 0.13 210

ILOS010T120407 0.7 1100

ILOS010T060407 3.5 5600

ILOS030T010407 Omega, 30 kDa 0.065 100

ILOS030T020407 0.13 210

ILOS030T120407 0.7 1100

ILOS030T060407 3.5 5600

Loading...

Loading...