16

5. Pump one hold-up volume through the module and into a separate retentate vessel. Repeat

this step, each time pumping one hold-up volume into a separate retentate vessel. The

number of recovery flushes performed should be defined by the application and the targeted

recovery yield. This recovery step should be optimized for each application.

6. Stop the pump.

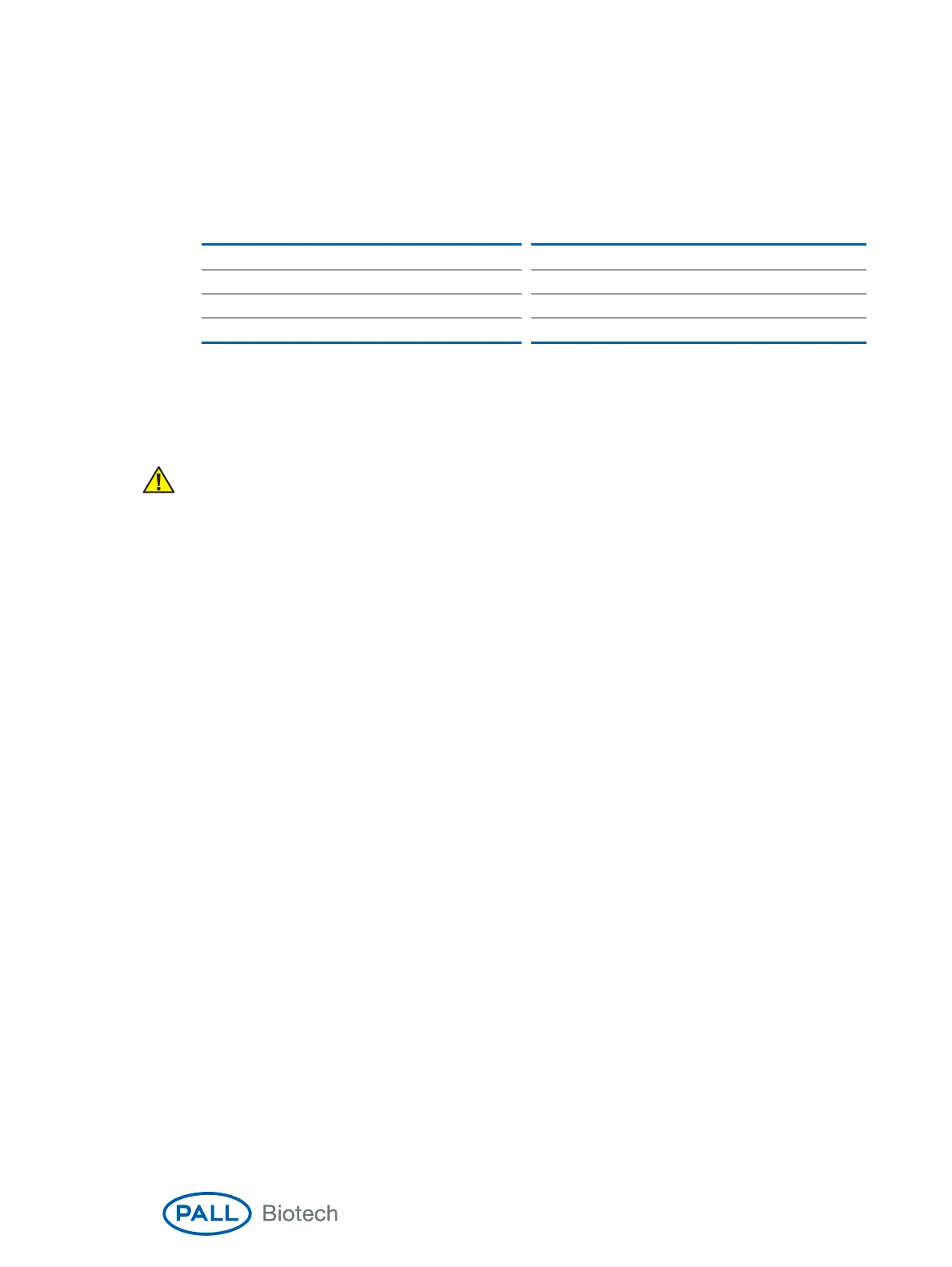

Table 4

Approximate minimum hold-up volumes for Cadence ILC modules

Module Size Minimum Module Hold-Up Volume*

T01 (0.065 m

2

) 20 mL

T02 (0.13 m

2

) 40 mL

T12 (0.7 m

2

) 200 mL

T06 (3.5 m

2

) 1,300 mL

* Actual total hold-up volume should be determined based on the setup. (See Procedure F)

Part 1 — Pre-Use Conditioning

and

Part 2 — Processing

are now complete. The user is ready

to begin

Part 3 — Post-Use Conditioning

which is optional and applicable only if the Cadence

ILC is to be reused. Otherwise, to proceed with

Part 4 – Post-Use Disposal

WARNING!

The Cadence ILC Module is a disposable device. It could potentially be used

several times. However, specific end-user studies should be conducted to identified the limited

re-use range and validate specific re-use requirements per application.

5.4 Part 3 — Post-Use Conditioning

After completing product recovery, clean, test, and prepare the Cadence ILC module for

storage or reuse in case the module would be utilized for multiple batches or for a specific

campaign. This section is optional and is not applicable when considering single-use processes.

Document and validate the cleaning process for biopharmaceutical applications.

u

Procedure K — Clean the Cadence ILC Module

If a sufficient amount of product has been removed from the module with buffer flushing during

product recovery, proceed directly to cleaning steps below.

If product must be flushed from the module with purified water or buffer before beginning

the cleaning step, follow Procedure B (Flush the Cadence ILC module). Then go to the

Cleaning Steps

below.

Cleaning Steps

Follow these steps to clean the Cadence ILC module and system:

1. Connect the feed line to a supply of cleaning solution (see Materials Section 5.1) at ambient

temperature.

2. Direct the retentate and permeate lines to drain.

3. Fully open the feed, retentate, and permeate 2 lines. Close the permeate 1 line.

4. Start the feed pump and adjust the feed pump speed to deliver a feed pressure of

1.4 – 4.1 barg (20 – 60 psig).

5. Open the permeate 1 line for 30 seconds and then close for the remainder of the

cleaning step.

6. – For Delta membranes: Stop the feed pump after 45 – 50 L/m

2

of cleaning solution

passes through the module.

– For Omega membranes: Stop the feed pump after 20 L/m

2

of cleaning solution passes

through the module. Then, introduce 30 L/m

2

of fresh cleaning solution and recirculate

at 1.4 – 4.1 barg (20 – 60 psig) for 1 hour with the permeate ports closed.

Loading...

Loading...