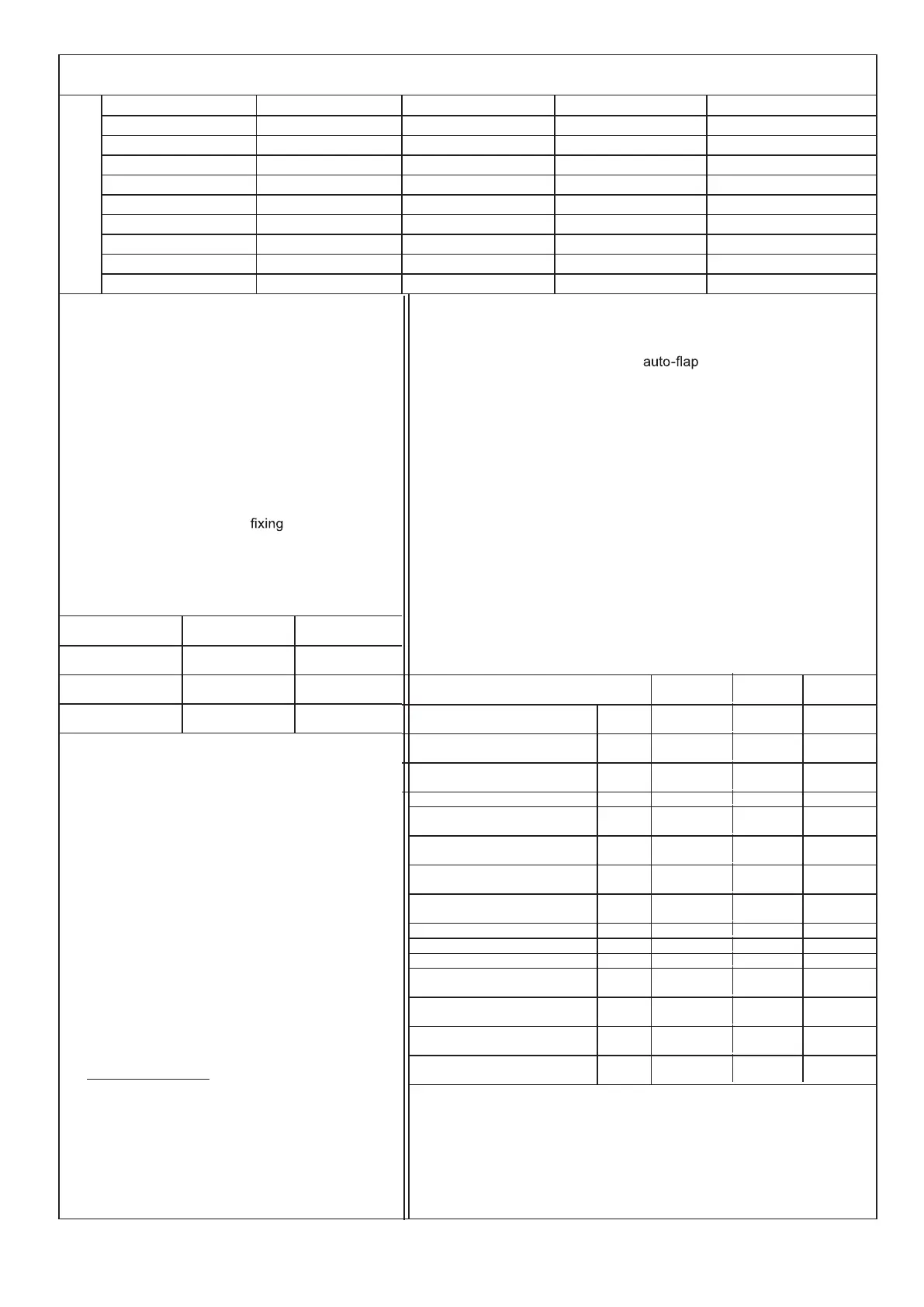

GHP Test Run Checklist

Model Name: U-

Manufacturing No.:

Indoor

1)S- 11)S- 21)S- 31)S- 41)S-

2)S- 12)S- 22)S- 32)S- 42)S-

3)S- 13)S- 23)S- 33)S- 43)S-

4)S- 14)S- 24)S- 34)S- 44)S-

5)S- 15)S- 25)S- 35)S- 45)S-

6)S- 16)S- 26)S- 36)S- 46)S-

7)S- 17)S- 27)S- 37)S- 47)S-

8)S- 18)S- 28)S- 38)S- 48)S-

9)S- 19)S- 29)S- 39)S-

10)S- 20)S- 30)S- 40)S-

1. Installation check

·

Equipment external visual, damage, missing

parts check (outdoor unit)

·

Equipment external visual, damage, missing

parts check (indoor unit)

·

Indoor unit/outdoor unit installation condition check

·

Outdoor unit anti-vibration mat, cradle condition

·

Drain tubing condition (outdoor unit)

·

Drain tubing condition (indoor unit)

·

Refrigerant tubing connections leak check

(air-tightness test)

·

Electrical power wire, signal wire connection

condition check

·

Removal of the indoor unit pad

·

Earth installation check

·

Leakage current breaker installation check

·

Amount of additionally charged refrigerant

check (kg)

·

Refrigerant tubing length (m)

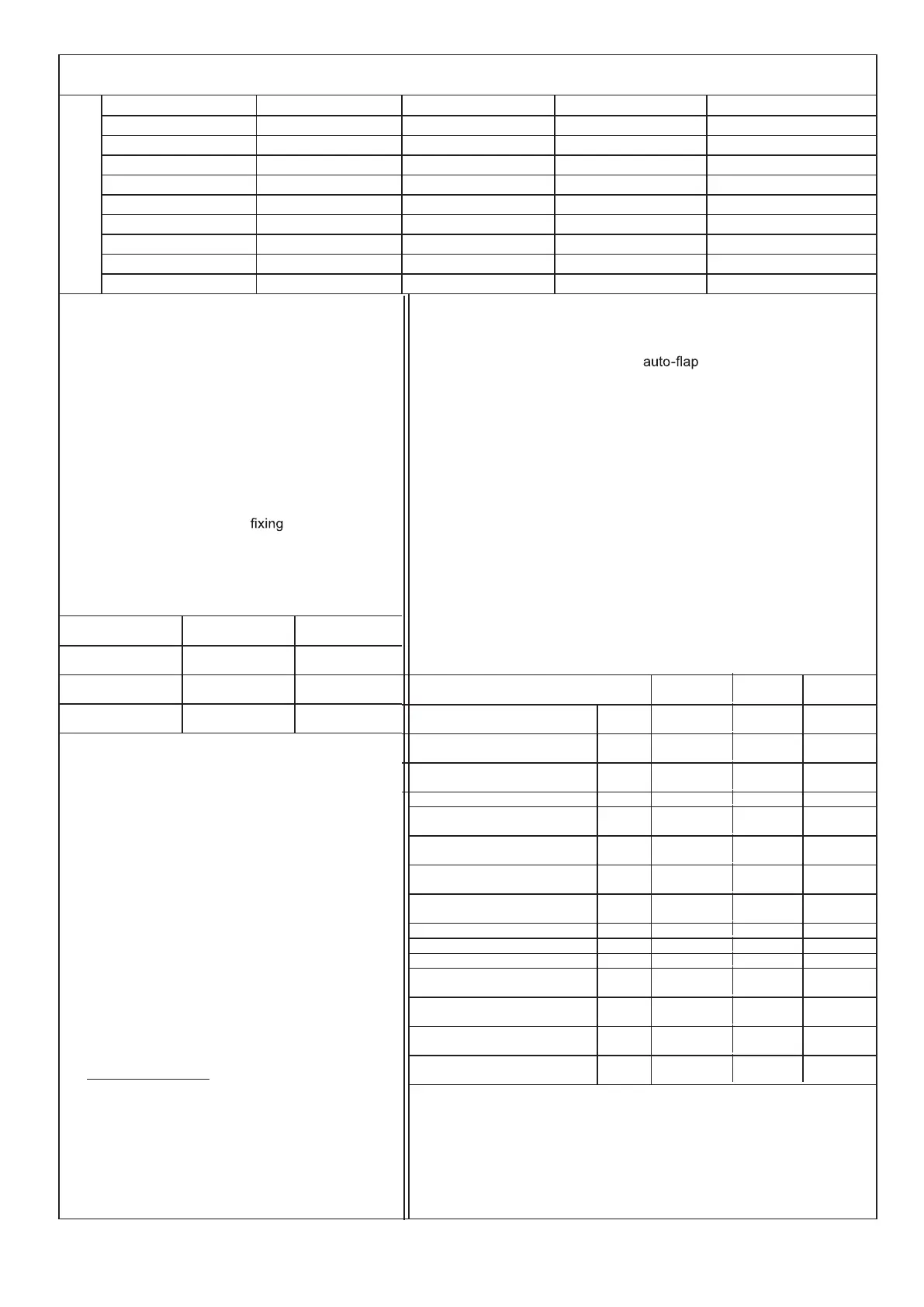

4. Engine system check

·

Engine starting condition (starting performance)

·

Error vibration and sound check

·

Check for external leak of oil and coolant

·

Harness installation state

5. Operation data collection

·

Data collection

·

[Operating mode:

·

After operation min.]

·

(Operate all indoor units, and take measurements)

Max. Min.

Outd

oor unit operation data

Outdoor

unit 1

Outdoor

unit 2

Outdoor

unit 3

Main tubing length -

Measurement item (sensor

name)

Unit

Measure-

ment value

Measure-

ment value

Measure-

ment value

Branch tubing

length

Number of engine revolu-

tions

min

-1

High/low differ-

ence

Compressor inlet pressure MPa

·

Insulation resistance check (Power Equipment)

Power side MΩ

Equipment side MΩ

·

Fuel tubing connectors leakage check

2. Checks and preparations before operation

·

Crankcase heater energized for 5 hours

·

Opening of closing valve (liquid side, gas side)

·

Check power phase

·

Fuel gas type check and setting

·

Coolant level check

·

Stop switch setting

·

Gas solenoid valve switch setting check

·

Number of indoor units connected setting

·

Outdoor unit address and terminal resistance

setting

·

Check of date and time, and adjustment

·

ROM version number check

·

Ver

Compressor outlet pressure MPa

Compressor inlet tempera-

ture

°C

Compressor outlet tempera-

ture

°C

Outdoor heat exchanger

inlet temperature

°C

Outdoor heat exchanger

outlet temperature

°C

Outdoor air temperatur

Coolant temperature °C

Outdoor fan temperature %

Degree of opening of out-

door unit solenoid valve

step

Degree of opening of out-

door unit liquid valve

step

Degree of opening of out-

door unit bypass valve

step

Degree of superheat of com-

pressor i

ntake

°C

(Units: Degree of opening: Step; Temperature °C)

OK: ○, NG: ×, Satisfactory after maintenance: ●, Work complete:

〆

, Not applicable: -, Adjusted: A, Tightened: T, Cleaned: C, Filled: L, Changed: E

°C

3. Function check

● Remote controller

·

Operation check

·

Check of changing air velocity and

operation

·

Temperature setting check

● Central control function

·

( )

·

Operation check

Loading...

Loading...