30

●

Be sure to insulate both the gas tubing and liquid tubing.

In addition, wrap the supplied insulation material around

the tubing joints, and fasten in place with vinyl tape or other

means. Failure to insulate the tubing may result in water

leakage from condensation.

●

Plug all gaps at tube through-holes in the unit with insulation

or a similar substance to prevent air leakage.

●

When connecting an embedded ceiling type unit (like this

one) to a refrigerant system where individual operation is

possible, install 2 RAP valve kits (CZ-P160RVK2) in parallel.

(For details on connecting the RAP valve kit, refer to the

manual that came with the kit.)

Fig. 3-78

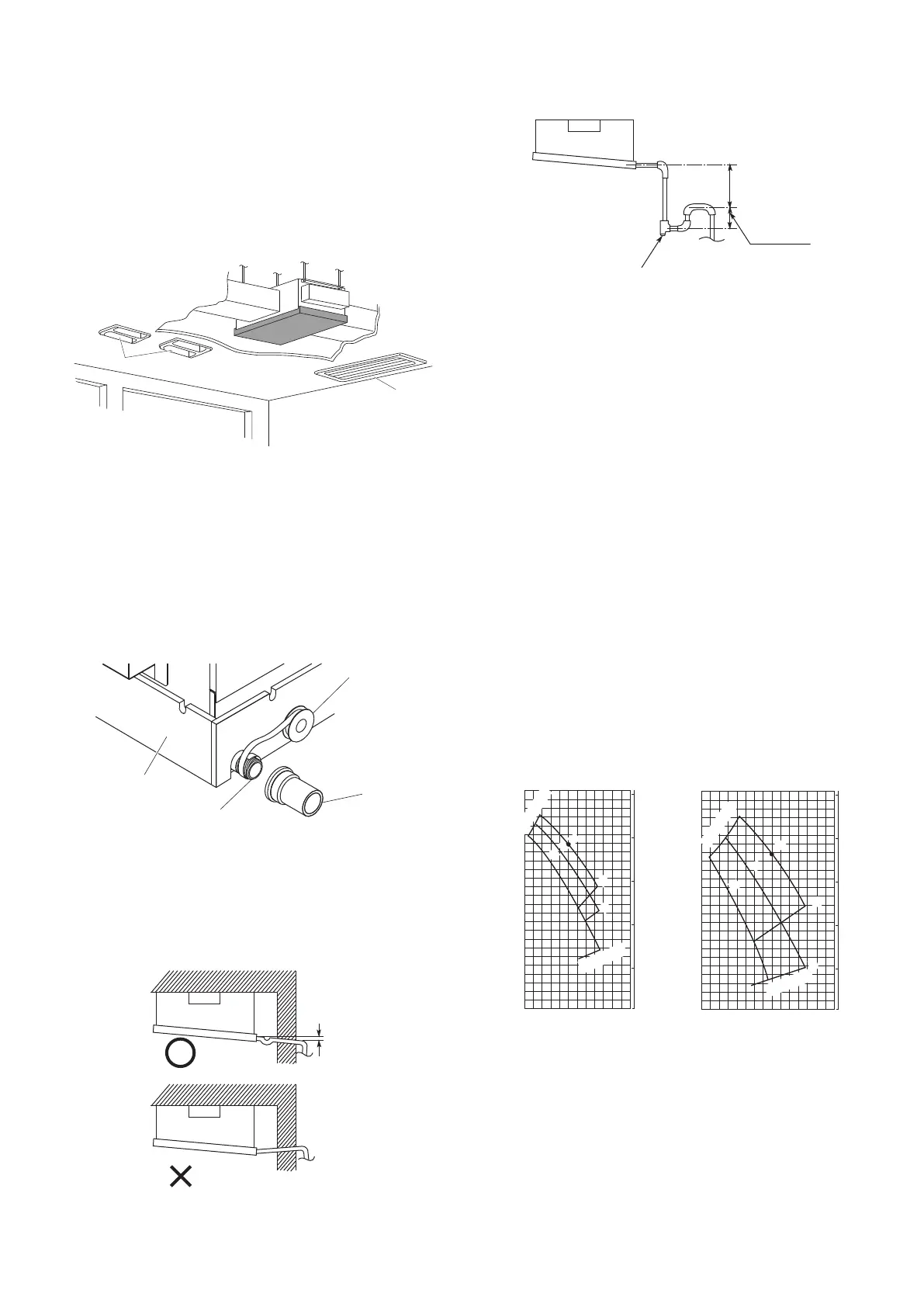

3-29. Installing the Drain Piping

(1) Prepare standard hard PVC pipe (O.D. 32 mm) for the

drain and use the supplied drain socket to prevent water

leaks. The PVC pipe must be purchased separately.

When doing this, apply adhesive for the PVC pipe at the

connection point.

(2) If connecting a drain joint (supplied) to the threaded drain

port, first wrap the drain port threads with sealing tape,

then connect the joint. (Fig. 3-79)

Fig. 3-79

(3) After connecting the drain pipe securely, wrap insulator

(field supply) around the pipe.

(4) Ensure the drain pipe has a downward gradient (1/100 or

more) and prepare traps as indicated in Fig. 3-80.

Fig. 3-80

(5) Also, in another part of the pipe arrangement, prepare

traps with an inspection plug to clean dust or debris that

may cause leaking of water. (Fig. 3-81)

Fig. 3-81

(6) After connecting the drain piping, slowly pour water into the

drain pan to check that the water drains smoothly.

3-30. Caution for Ducting Work

●

This unit has high static pressure (applicable external static

pressure Max. 167 to 216 Pa (17–22 mm Aq). In the case of

small pressure resistance (for instance, a short duct), install

a damper for adjusting air flow volume as air flow volume /

air flow noise increases.

●

If the air conditioner is to be installed in a room such as

an office or meeting room which needs a low sound level,

provide a supply and return noise absorption chamber with

an acoustic liner.

●

Include an air filter (field supply) at the return duct.

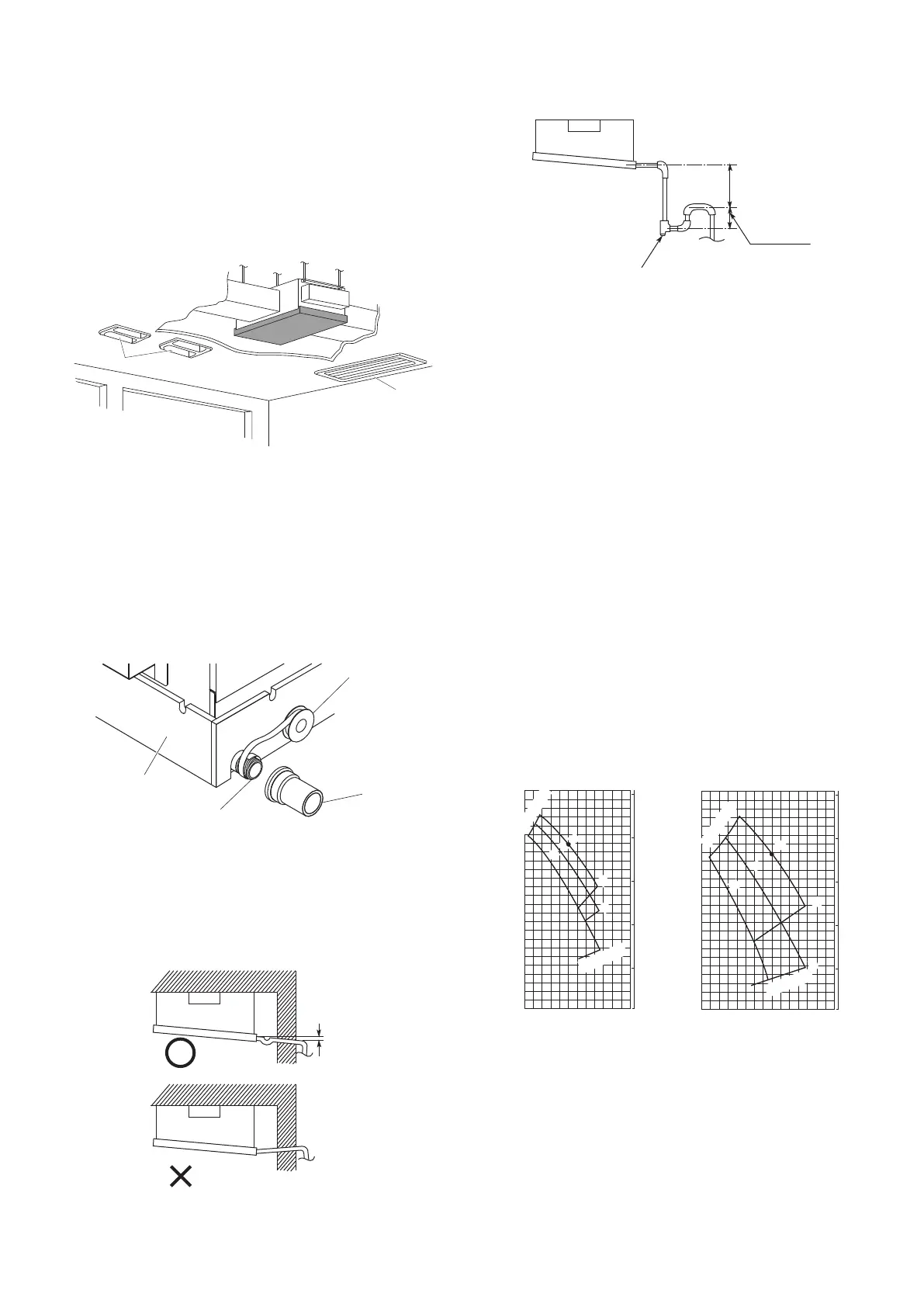

Indoor Fan Performance

How to Read the Diagram

The vertical axis is the External Static Pressure (Pa) while

the horizontal axis represents the Air Flow (m

3

/minute). The

characteristic curve for the “H,” “Med,” and “Lo” fan speed

control.

The nameplate values are shown based on the “H” air flow.

Therefore in the case of 73 Type, the flow is 23 m

3

/minute,

while the External Static Pressure is 190 Pa at “H” position. If

the external static pressure is too great (due to long extension

of duct, for example), the air flow volume may drop too low at

each air outlet.

H

H

M

M

L

20

0

5

10

15

20

25

25 30

(P a)

50

0

100

150

200

250

(mmAq)

H

H

M

M

L

25 30 35

0

5

10

15

20

25

(P a)

50

0

100

150

200

250

(mmAq)

Drain pan

Sealing tape

Drain opening

(25A male screw)

Drain joint

(supplied)

Min. 1/100

Downward gradient

Good

Not good

Inspection plug

Min. 50 mm

Min.

100 mm

73 Type

Air Flow (m

3

/minute)

External Static Pressure

Limit line

Limit line

106 Type

Air Flow (m

3

/minute)

External Static Pressure

Limit line

Limit line

Air-outlet grille

Air-intake grille

Panaindoor336013Eng.indb30Panaindoor336013Eng.indb30 2012/03/2121:07:132012/03/2121:07:13

Loading...

Loading...