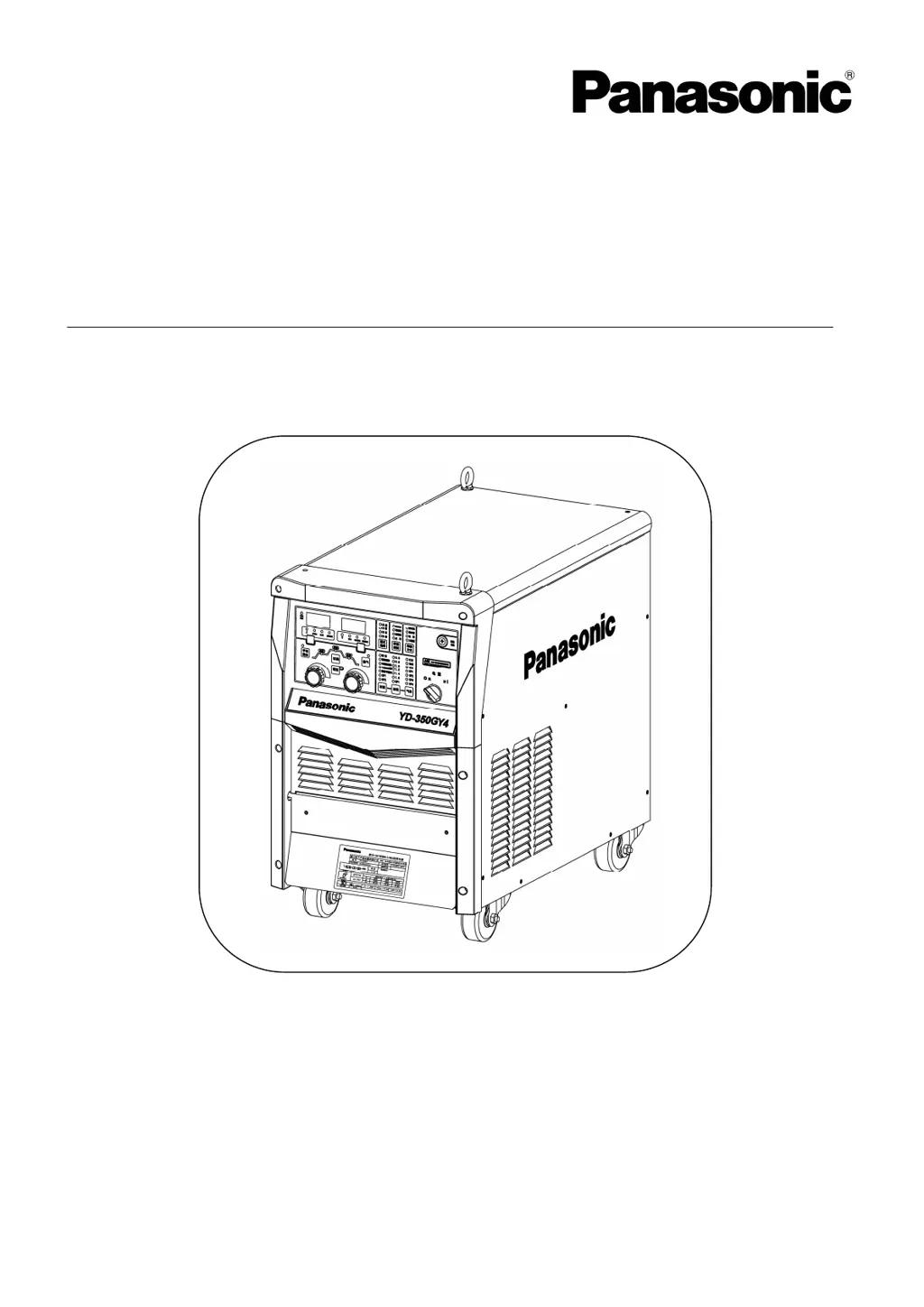

What to do if Panasonic YD-350GY4 Welding System shows temperature rise error?

- TTony RichardsAug 6, 2025

If your Panasonic Welding System indicates a temperature rise error, allow the unit to cool down without turning it off. Keep the input power in a no-load state and wait. The error should clear automatically once the power source cools. Also, inspect the system for any factors contributing to overheating, such as excessive duty cycle or blocked airflow at the ventilation and cooling fan windows. If the problem persists, try cleaning the cooling fan.