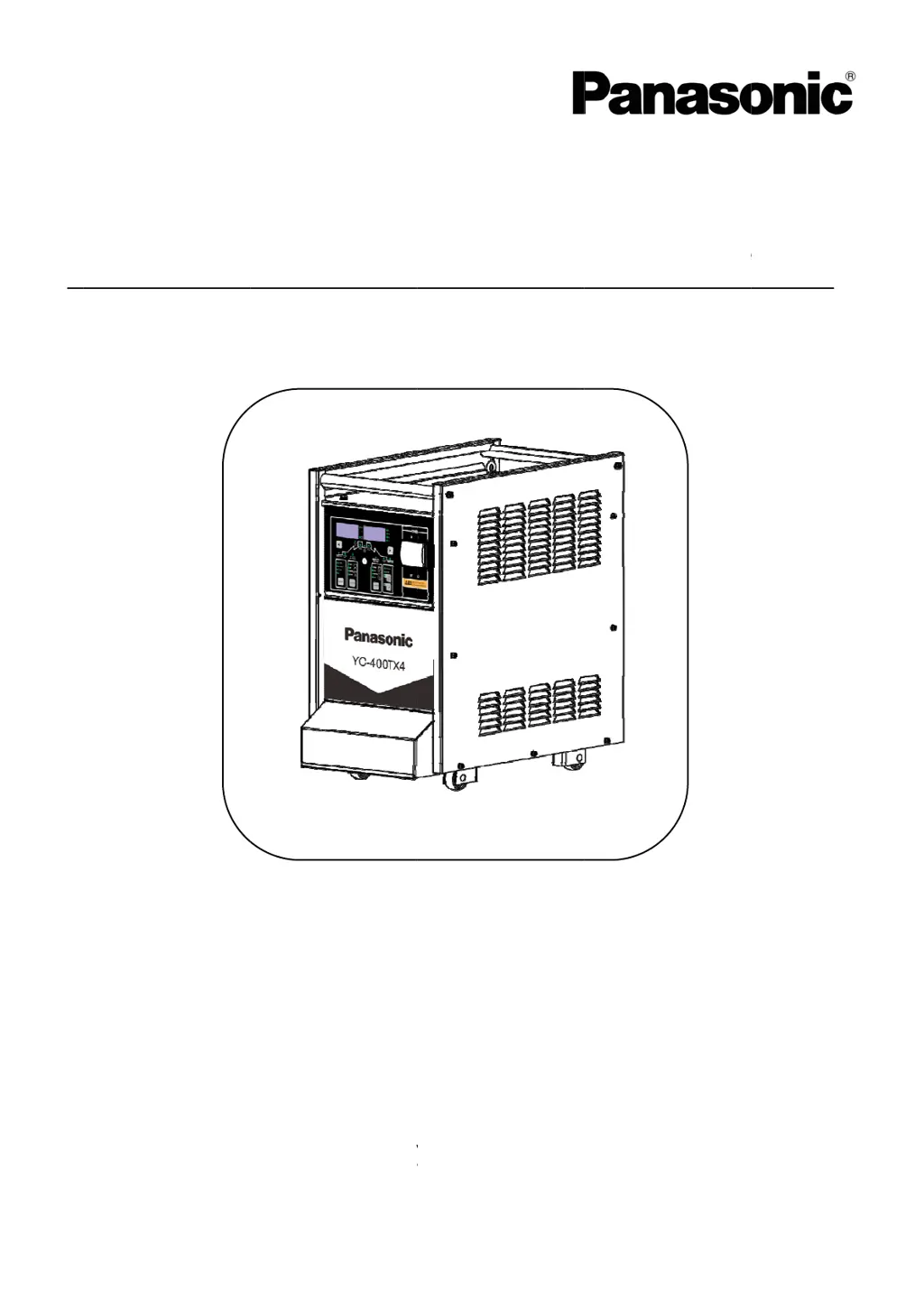

What to do if Panasonic Welding System shows temperature rise error?

- JJane JonesAug 6, 2025

If the Panasonic Welding System shows a temperature rise error, first, do not turn off the machine immediately; allow the temperature to decrease. Ensure the input power remains in a no-load state and wait. Examine the unit for overheating causes, such as airflow blockage at ventilation and cooling fan windows or exceeding the duty cycle, and remove them. If the issue persists, clean the cooling fan.