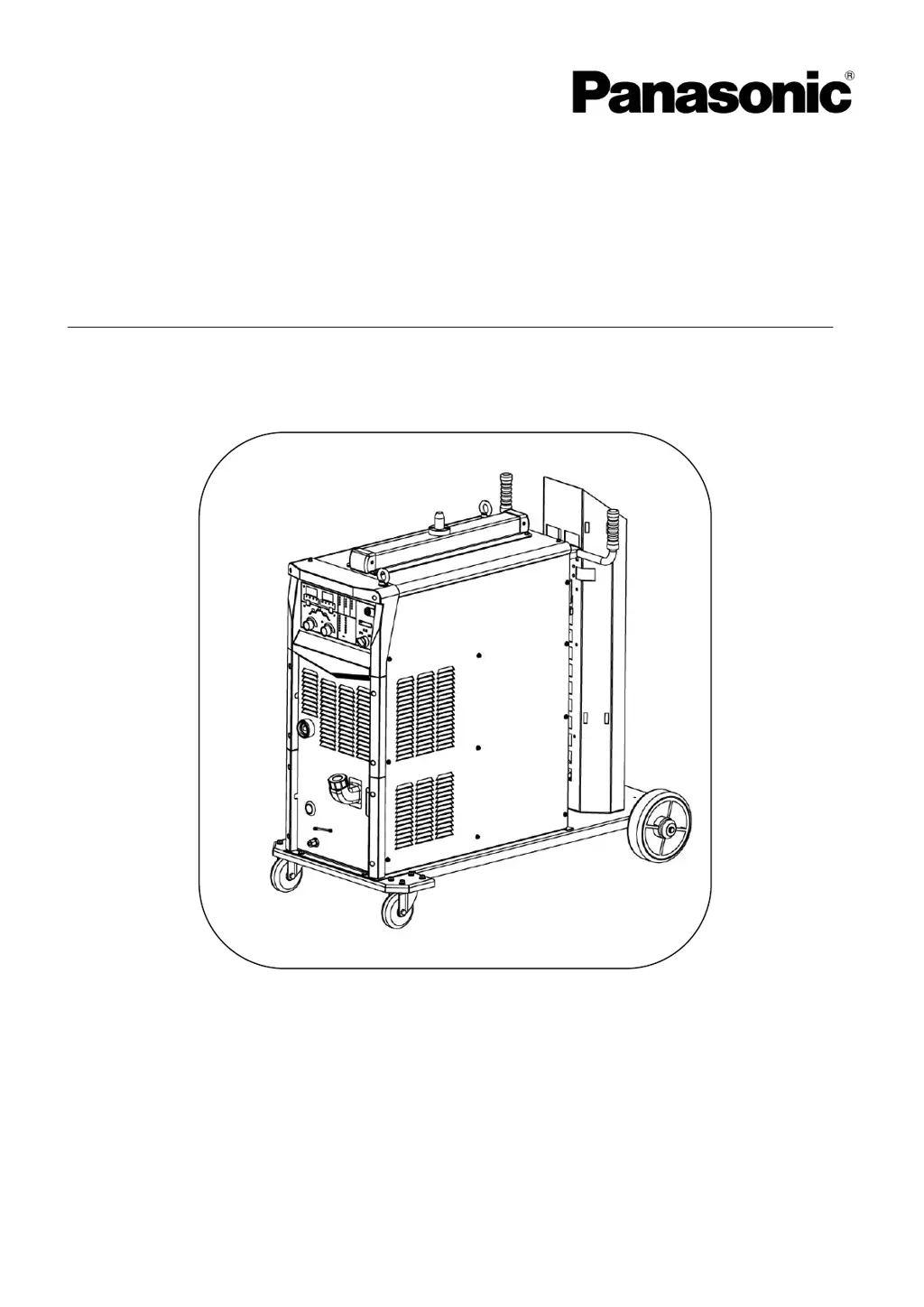

Why does my Panasonic YD-350FD2 show a temperature rise error?

- JJennifer HolderAug 19, 2025

If you get a temperature rise error on your Panasonic Welding System, it could be due to a rise in temperature inside the welding power source, over duty cycle or airflow blockage at ventilation and cooling fan windows. Do NOT turn OFF the machine before the temperature in the Product decreases. Keep the input power in no load state and wait for a while. Check and remove causes of over-heat. If the problem persists, clean the cooling fan.